Choosing a 3PL food logistics provider isn’t just another procurement task—it's a critical investment in your brand’s integrity, your customers’ safety, and your operational future. Get this wrong, and you're not just looking at spoiled products. You're facing costly recalls, hefty regulatory fines, and a partnership that could sink your business.

Why Your 3PL Food Logistics Partner Is Mission Critical

When you’re entrusting a partner with food or health-related products, you need to go far beyond simple cost comparisons. The scrutiny has to be almost forensic. The risks are enormous, from financial losses due to spoilage all the way to irreversible brand damage from a public recall. Unlike standard logistics, food supply chains are governed by iron-clad regulations where a single temperature slip-up or a cross-contamination incident can have disastrous consequences.

This is exactly where a specialized 3PL food logistics provider becomes essential. They are the guardians of your product's quality and safety, from their warehouse doors to the final destination. The global third-party logistics market is already huge—projected to hit USD 1.48 trillion by 2030. But within that, the specialized food logistics segment is growing fast, expected to reach $222.44 billion by 2033. That growth underscores just how complex and important this niche is. You can dig into more details in this global market analysis of the 3PL industry.

The True Cost of a Poor Partnership

The financial fallout from a bad logistics partnership goes way beyond lost inventory. Just think about the potential ripple effects:

- Costly Recalls: A single recall can drain millions in logistics, product destruction, and legal fees. And that doesn't even touch the long-term loss of consumer trust.

- Regulatory Penalties: Failing to comply with regulations like the Food Safety Modernization Act (FSMA) can lead to crippling fines and even operational shutdowns.

- Reputational Damage: In our hyper-connected world, a food safety issue can explode into a public relations nightmare overnight, destroying the brand equity you've spent years building.

Lessons from Umoja’s Procurement Process

Our experience sourcing and managing logistics for complex public health programs has taught us some hard-won lessons. As the Umoja Health leadership team can attest, a great partnership is built on transparency, proven capabilities, and a shared commitment to the mission. We quickly learned that the best questions to ask during the vetting process are the ones that demand documented proof, not just verbal promises.

A premier 3PL doesn't just promise compliance; they provide the auditable data trails, validation reports, and real-time visibility to prove it. This is the fundamental difference between a vendor and a true partner.

This guide is the result of those experiences, distilled into a practical framework. It’s designed to help you get past the surface-level sales pitches and ask the tough questions that reveal a provider's true operational DNA. We’ll give you the tools you need to assess their compliance, technology, and commitment, ensuring your chosen partner acts as a resilient extension of your own brand.

Building Your Vetting and Evaluation Framework

Before you even think about sending out an RFP, you need a bulletproof internal framework. This isn't just a simple checklist; it's your strategic playbook for telling a 3PL's marketing pitch apart from their real-world operational muscle. A solid framework means every potential 3PL food logistics provider gets measured by the same exacting standards.

Your evaluation has to start with the absolute non-negotiables of food safety. This means you have to push beyond simple "yes/no" questions and demand documented proof of their compliance and day-to-day rigor. The goal is to get a crystal-clear picture of how they actually operate before a contract is ever on the table.

Getting this foundational step right prevents incredibly costly surprises down the road. It forces a potential partner to show you, not just tell you, that they know how to handle sensitive food products.

Core Competencies That Demand Proof

A true food-grade 3PL runs on a foundation of documented, verifiable processes. Your vetting framework needs to be sharp enough to scrutinize these core areas because they are the literal backbone of a safe supply chain. Vague assurances are a major red flag; you have to demand the paperwork.

Here are the key areas to validate:

- FSMA & HACCP Compliance: Don't just ask if they are compliant. Ask for their Food Safety Modernization Act (FSMA) plan and their Hazard Analysis Critical Control Point (HACCP) documentation. A confident, capable provider will have these ready to go, clearly outlining how they prevent specific food safety hazards.

- Temperature Control Validation: It's not enough to know they have cold storage. Request temperature mapping studies for their warehouses and their trailers. This is the only way to prove temperatures are consistent across the entire space, eliminating the dangerous hot spots that can ruin a product. While you're at it, verify they have redundant power, like backup generators.

- Allergen & Cross-Contamination Protocols: Ask for a copy of their Standard Operating Procedures (SOPs) for allergen control. This document should detail everything from how they physically segregate allergenic products to the sanitation verification they perform between runs.

This isn't overkill; this level of scrutiny is fast becoming the industry standard. The United States 3PL market is gearing up for massive growth and is projected to expand by USD 132.3 billion between 2025 and 2029. In such a competitive space, the best providers are using advanced cold chain management and robust tech systems to stand out. You can learn more about these trends in the U.S. 3PL market.

A critical lesson I've learned from years of complex procurement is that the most insightful questions are the ones that ask "how" and "show me," not just "do you." A provider's willingness and ability to produce validation reports, SOPs, and audit results speaks volumes about their transparency and operational maturity.

Questions to Ask That Reveal a 3PL's True DNA

To get past the glossy brochures and canned RFP responses, you need questions that probe the reality behind the promises. The table below isn't your generic checklist; these are the kinds of questions that reveal a provider's true capabilities. They're designed to test not just if a system exists, but how effective and resilient it is under real pressure.

| Category | The Uncommon Question to Ask | Why It's a Critical Differentiator |

|---|---|---|

| Pest Control | "May I see your pest control logbooks and the trend analysis reports from your third-party provider for the last six months?" | This moves way beyond a simple "yes, we have pest control." It reveals the service frequency, pinpoints recurring issues, and shows how proactively they use data to prevent infestations—a core FSMA requirement. |

| Employee Training | "Describe your onboarding and continuous training program for food handling. Can you provide sanitized training records and competency assessments?" | A strong answer reveals a documented, ongoing training program, not a one-and-done orientation. This is your proof of their commitment to maintaining a workforce trained on GMPs, allergen handling, and food defense. |

| Technology & Traceability | "During a mock recall, what is your guaranteed response time to provide a full traceability report, and can you demonstrate this capability live in your WMS?" | This puts their system to the test. A top-tier provider can execute a mock recall and generate detailed, lot-level traceability reports in minutes, not hours. They'll also be confident enough to demo it for you on the spot. |

| Corrective Actions | "Walk me through your CAPA (Corrective and Preventive Action) process for the last time a client-critical KPI was missed. What was the root cause and what documented changes were made?" | This question tests for a culture of accountability and continuous improvement, not blame. It shows you how they diagnose problems, implement fixes, and verify that those fixes actually work to prevent a recurrence. |

| Business Continuity | "What specific communication protocols and operational pivots are in your plan if your primary facility becomes inaccessible due to a natural disaster?" | This question assesses resilience far beyond a backup generator. It shows you how they would manage customer communication, reroute inventory, and deploy resources from other sites to keep your business running. |

Uncovering A 3PL Provider's True Capabilities

Once you’ve got your internal framework dialed in, it’s time to look outward and start probing potential partners. This is where you dig past the slick marketing brochures and get a real look at their day-to-day operations. A top-tier 3PL food logistics provider won’t just give you answers; they’ll show you the documented proof of their processes, systems, and how they handle pressure.

The point here isn’t to catch them in a mistake. It’s to truly understand the depth of their operational maturity. If you ask superficial questions, you’ll get superficial answers. To really separate a capable partner from a potential liability, your questions need to be specific, evidence-based, and designed to reveal their actual strengths and weaknesses.

Going Beyond The Standard RFP

A standard Request for Proposal is an open invitation for canned, pre-approved marketing speak. To get a genuine feel for what a provider can do, you have to ask questions that force them to demonstrate their processes, not just talk about them. This means asking to see specific reports, logs, and procedural documents that prove their systems work the way they say they do.

This approach creates a level of transparency that quickly weeds out the pretenders. It's not just about what services they offer; it's about finding a partner whose operational DNA matches your needs. The best way to do that is to get into the weeds of how they manage the things that matter most in food logistics, from cold chain integrity to business continuity. Getting perspective on finding a logistics partner who truly understands your business can offer some valuable outside insights into this critical evaluation process.

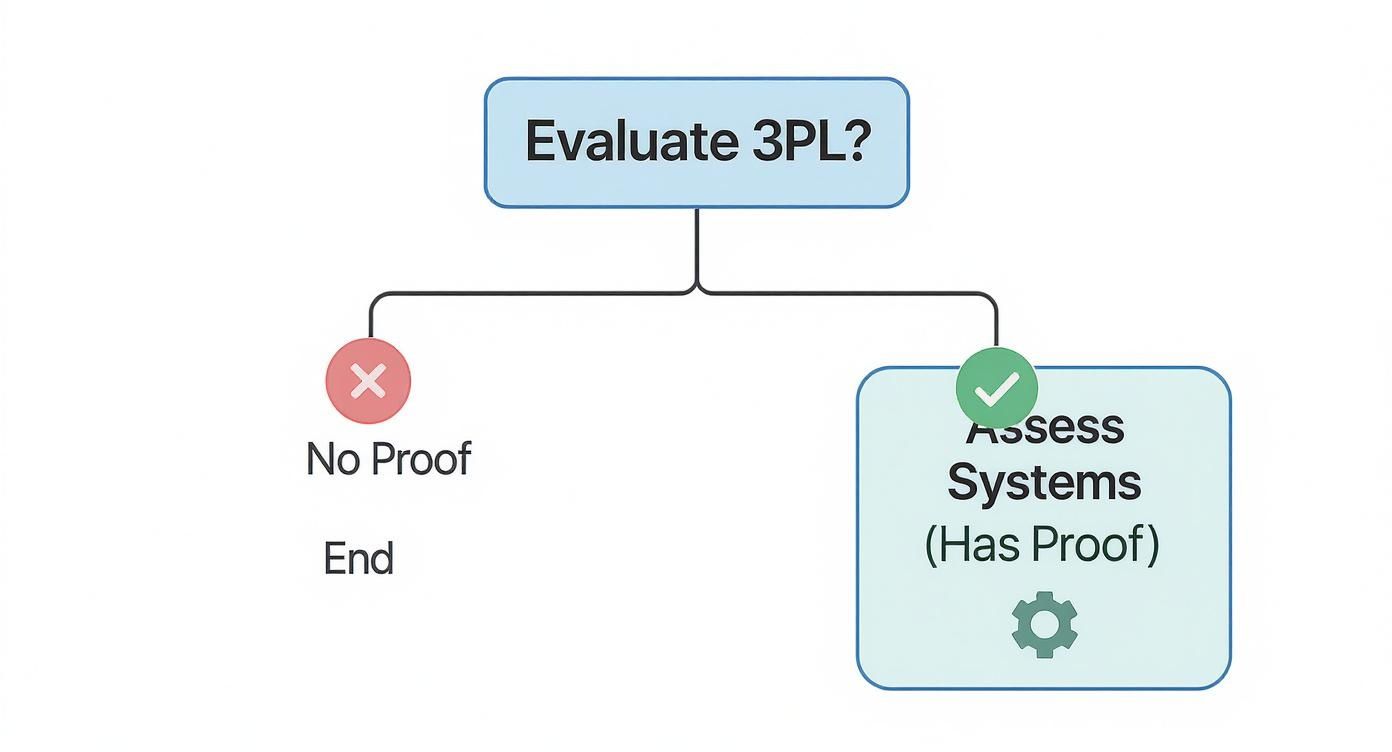

The decision tree below maps out a simple but effective way to approach this vetting process. Notice the emphasis on getting proof before you go any further.

This visual underscores the most important first step: always demand verifiable proof before you invest more of your team's time evaluating a provider’s systems.

A Deeper Dive With Advanced Vetting Questions

The table below is your playbook for asking the tough questions—the ones that can’t be answered with a simple "yes." Each one is designed to peel back the layers of a 3PL’s operations, giving you a clear view of their compliance, technology, and contingency planning. At Umoja, our experience has taught us that these are the questions that expose potential gaps before they become your problems. This is especially vital when we vet partners for our own specialized logistics and distribution solutions.

A provider's reaction to these detailed questions is as telling as their answers. A true partner welcomes deep scrutiny and is prepared to back up their claims with data and documentation. Hesitation or deflection is a significant red flag.

When you ask the right questions, you get a window into how a provider thinks, how they solve problems, and just how prepared they are for the unexpected.

The following questions go far beyond a standard RFP. They are designed to force a detailed, evidence-based conversation that reveals a 3PL's true operational strength.

Advanced Vetting Questions for Your Potential 3PL Food Logistics Provider

| Category | Question | What a Strong Answer Looks Like |

|---|---|---|

| Compliance | "Describe your sanitation verification process between allergen runs. Can you provide the last three validation reports, including ATP swab test results?" | A strong provider will immediately produce detailed SOPs and validation reports. They will confidently explain their sanitation methods, the specific tests used (like ATP swabs), and the corrective actions taken for any failed tests, proving their allergen control program is active and effective. |

| Cold Chain Integrity | "Provide a temperature mapping study for one of your refrigerated zones and explain how you use this data to determine product placement and sensor locations." | This goes beyond "we monitor temperatures." A top-tier 3PL will provide a formal study showing temperature variations and explain how it informs their storage strategy to avoid hot spots. They will also show you real-time sensor data from their monitoring platform. |

| Technology Integration | "Walk us through the process and timeline for integrating our ERP with your WMS. What are the key data points you require for a seamless EDI connection?" | A capable partner will have a documented, phased onboarding plan. They can clearly define the necessary data fields (e.g., PO numbers, lot codes, expiration dates) and provide a realistic timeline, demonstrating experience with complex integrations. |

| Business Continuity | "Beyond power outages, detail your contingency plan for a labor shortage or a regional transportation disruption. How would you prioritize client orders?" | This tests their operational resilience. A robust answer includes cross-training programs, relationships with temporary staffing agencies, and partnerships with a diverse carrier network. They should also have a clear, documented protocol for client communication and order prioritization during a crisis. |

Using these questions as a starting point will fundamentally change the dynamic of your vetting process. You'll move from a passive recipient of information to an active investigator, ensuring the partner you choose is genuinely equipped to handle the complexities of your business.

Meeting Specialized Program Logistics Requirements

Standard food logistics is already a tough business. But logistics for government and health programs? That’s another level entirely. A generic 3PL food logistics provider simply doesn't have the specialized systems or deep compliance knowledge needed for programs with ironclad rules, like the Summer Food Service Program (SFSP), WIC, or Medicaid-funded meal deliveries.

These aren't just about moving boxes from A to B. They are mission-driven operations where real people depend on perfect execution. The right partner understands that a late delivery isn't just an inconvenience—it's a child missing a meal. This requires a precision that goes far beyond what you'd find in a typical commercial contract.

Private equity and institutional investors are definitely taking notice. The food logistics market is expected to jump from USD 122.23 billion in 2024 to USD 222.44 billion by 2033. This growth highlights the surging demand for true experts who can navigate these incredibly complex supply chains.

Navigating Program-Specific Mandates

Every government or health program has its own unique set of logistical challenges. A 3PL that’s great in one area might be completely out of its depth in another, which is why you have to vet for specific, proven experience.

- Complex Kitting and Assembly: Programs like SFSP or CACFP often need multi-day meal kits. This means assembling various components into a single package, demanding pinpoint inventory management and an assembly process that guarantees both accuracy and food safety.

- Strict Delivery Windows: Whether it's a beneficiary pickup or a home delivery, the schedule is everything. A 3PL has to operate a rock-solid last-mile delivery network with real-time tracking to hit these non-negotiable deadlines.

- Beneficiary Data Privacy: For any Medicaid-funded meal program, your 3PL will be handling Protected Health Information (PHI). This makes HIPAA compliance an absolute deal-breaker, requiring secure data protocols and rigorous employee training.

In mission-driven logistics, failure is not an option. A premier 3PL must demonstrate not just the ability to execute but the resilience to adapt, whether that means managing complex kitting for nutrition programs or rapidly scaling for disaster response.

When you're vetting a provider, you absolutely have to confirm their grasp of all relevant food safety symbols and regulations. This ensures every single item is handled, labeled, and stored correctly from the moment it enters their facility.

The Disaster Response Litmus Test

Nothing shows you what a 3PL is really made of like a disaster response situation. When a hurricane, flood, or fire hits, that logistics partner becomes a frontline responder. It’s the ultimate stress test of their scalability, problem-solving skills, and operational integrity under pressure.

In a crisis, a 3PL has to:

- Rapidly Scale Operations: They need to get assets moving, lock down transportation, and boost staffing almost overnight to handle a huge influx of emergency supplies.

- Manage Unconventional Distribution: Forget standard loading docks. Deliveries are going to emergency shelters, community centers, and makeshift sites, which demands incredibly flexible last-mile solutions.

- Maintain Product Integrity: Even in total chaos, cold chain integrity and food safety can't be compromised. The provider must have the systems to track and protect product quality, no matter what.

This kind of analysis shows why you can't afford to skip the details when vetting for specialized capabilities. Whether it's handling the fine print of government kitting programs or pulling off a flawless disaster response, you need a partner who was built for the complexities of your mission.

Defining Your RFP and Service Level Agreements

Once you have your evaluation framework locked in, it's time to turn it into the documents you'll actually use for procurement. A generic Request for Proposal (RFP) just won’t cut it when you’re vetting a 3PL food logistics provider. Your documents need to be sharp, specific, and designed to pull out the detailed, comparable bids that show what a provider can really do.

This is where your internal checklist becomes a binding set of expectations. Vague language gets you vague proposals, making a true side-by-side comparison impossible. Your RFP should be a litmus test, demanding proof and pushing potential partners to put their real expertise on display.

Crafting a Food-Specific RFP

Your RFP is the first formal step toward building real accountability. It must have clauses that force providers to go beyond slick marketing claims and show you the hard evidence of their compliance and operational muscle. This is how you prevent nasty surprises down the road and ensure everyone is aligned from day one.

Make sure to include specific language that requires bidders to submit:

- GFSI-Recognized Certifications: Don't just ask if they have one. Mandate they submit their current Safe Quality Food (SQF) or BRCGS certificate and the full audit report. A passing score isn't enough; you want to see the details. This proves their commitment to globally recognized food safety standards.

- Critical Standard Operating Procedures (SOPs): Ask for copies of their key SOPs. You’ll want to see their allergen control program, their sanitation verification process, and their mock recall procedure, at a minimum.

- Technology Stack Details: Require them to spell out the details of their Warehouse Management System (WMS) and Transportation Management System (TMS). You need to know its specific capabilities for lot tracking, EDI integration, and real-time temperature monitoring.

A well-crafted RFP doesn't just ask questions; it demands documentation. The goal is to make your expectations so clear that only a truly qualified food logistics partner can provide a satisfactory response.

Taking this detailed approach means the bids you get back will be full of actionable data. It lets you make your decision based on evidence, not just a gut feeling.

From Agreements to Accountability

After the RFP, your Service Level Agreement (SLA) is where you turn performance expectations into a contract. For food logistics, generic metrics like ‘On-Time Delivery’ are dangerously insufficient. Your SLAs and the Key Performance Indicators (KPIs) that measure them have to reflect the unique risks baked into the food supply chain.

You have to think in terms of outcomes that directly impact the safety and quality of your product. These are the KPIs that make performance measurable and hold your partner accountable for the things that actually matter.

Meaningful, food-specific KPIs should include:

- Temperature Deviation Incidents: Track the number of incidents per month where a product’s temperature goes outside its specified range. The goal here should always be zero.

- Order Fill Rate Accuracy: This needs to be measured by line item. The KPI tracks the percentage of orders shipped completely and correctly, which is absolutely critical for complex kitting programs.

- Mock Recall Response Time: How long does it take them to give you a complete traceability report—from the farm to the final delivery—for a specific lot? A top-tier provider should be able to do this in under an hour.

Kicking Off a Successful Partnership

Signing on the dotted line isn't the finish line; it's the starting gun. A truly seamless launch with your 3PL food logistics provider sets the tone for the entire relationship, turning all those contractual promises into day-to-day operational reality. Getting this right hinges on a structured, collaborative game plan that leaves absolutely no room for guesswork.

The very first move is to build a joint implementation team. This group needs key players from both your side and the 3PL's, covering the essential bases: operations, IT, quality assurance, and account management. This is your mission control, responsible for steering the project, keeping communication lines wide open, and making sure everything stays on schedule.

From Data Integration to Operational Readiness

Once the team is assembled, the immediate focus has to be on technology. The digital handshake between your Enterprise Resource Planning (ERP) system and their Warehouse Management System (WMS) is the absolute backbone of your partnership. This demands a detailed project plan with rock-solid timelines for setting up the Electronic Data Interchange (EDI) connections. These links are what automate the flow of everything from purchase orders to shipment confirmations, killing the risk of manual errors.

Before a single pallet of your product hits their receiving dock, you have to validate every single operational procedure. I mean every single one. This involves physically walking through each process on the warehouse floor—from receiving and inspection to the nitty-gritty of picking, packing, and shipping. This pre-launch dry run is your final, best chance to spot potential snags, get aligned on specific handling requirements, and confirm that your SOPs are understood and will be followed to the letter.

A Kitting Workflow Example

To put this in real-world terms, let's walk through a complex kitting process for something like a multi-day meal pack program. This is a common ask and a true test of a 3PL’s precision and quality control under pressure.

Sample Kitting & Assembly Workflow:

- 1. Bulk Product Receiving: The 3PL takes in bulk inventory—think cases of juice boxes, snacks, and shelf-stable entrées. Every pallet gets inspected, and lot numbers are scanned directly into the WMS.

- 2. Move to Kitting Zone: Products are then transferred from general storage to a dedicated, allergen-controlled kitting area. This isn't just a suggestion; it's a critical step for preventing cross-contamination.

- 3. Assembly Line Setup: The kitting line is physically configured based on the specific pack-out diagram for that meal box. Each station has a clear job, like adding one or two specific components.

- 4. In-Process Quality Checks: A supervisor is constantly performing random spot-checks at multiple points on the line. They’re verifying component accuracy, checking expiration dates (FEFO – First Expired, First Out is the rule), and making sure the packaging is perfect.

- 5. Final Labeling & Sealing: Once a kit is assembled, it's weighed to confirm everything is there. A final label—with the kit SKU, lot number, and expiration date—is applied before the box is sealed shut.

- 6. Palletization & Staging: The finished kits are stacked onto pallets, stretch-wrapped for stability, and moved to a designated outbound staging area, ready for shipment.

This kind of detailed, on-the-floor walkthrough ensures your partnership starts on solid ground. It helps you dodge the common pitfalls that can derail a new logistics relationship right out of the gate.

Frequently Asked Questions

When it comes to picking a 3PL food logistics provider, you're navigating a minefield of compliance rules, tech specs, and operational realities. Even with a solid plan, questions always pop up. Here are some straight answers to the most common ones we hear.

What Is the Biggest Mistake Companies Make?

Hands down, the most common and costly mistake is chasing the lowest price while ignoring compliance and actual capabilities. It’s easy to get drawn in by a low per-pallet or per-case rate, but that often means skipping the deep dive into a provider's food safety protocols, temperature control validation, and traceability systems.

This shortcut almost always leads to massive hidden costs down the road. We're talking product spoilage, rejected shipments, hefty regulatory fines, or even recalls that can shatter a brand's reputation. Think of a slightly higher price from a certified, tech-forward provider as an investment—one that protects you from risk and safeguards your brand.

How Important Is Technology Like WMS?

It's everything. You simply can't manage modern food logistics without it. A solid Warehouse Management System (WMS) is non-negotiable for lot tracking, ensuring proper First-Expired-First-Out (FEFO) stock rotation, and keeping allergens properly segregated.

And it's not just about what happens inside the warehouse. Real-time temperature monitoring and GPS tracking give you a live view of your products' entire journey. This isn't a luxury; it's what allows you to step in before a temperature deviation becomes a full-blown crisis. This tech is the foundation for ensuring food safety, hitting regulatory targets, and producing the clean audit trails you need to prove it.

Should We Choose a National or Regional 3PL?

The honest answer? It completely depends on your distribution map and what you need to get done. Big national players offer massive networks and can scale with you, which is great if you're shipping coast-to-coast. The trade-off is that they can sometimes be rigid when you have unique, hands-on requirements.

A key lesson from our work is that specialized needs, like complex kitting for government programs or last-mile delivery in rural areas, are often better served by a regional expert who offers more personalized service and deep local knowledge.

This is where smaller, regional providers shine. They often bring more flexibility and a tailored approach to the table. The best move is to vet providers based on their proven track record in the specific regions you operate in. Some companies even find a hybrid approach works best, using a national provider for the broad strokes and regional specialists for the finer details.

At Umoja Health, we deliver that perfect blend of nationwide scale and the specialized, hands-on service that complex food and health programs demand. Whether you need an FDA-registered 3PL for critical storage and kitting or a partner to manage mission-critical nutrition programs, we execute with precision and care. See how we can help at https://umojahealth.com.