Before you can fix a process, you have to know what a “good” process even looks like for your specific operation.

In the world of food logistics and programmatic fulfillment, generic solutions just don't cut it. The challenges of kitting nutrition boxes for seniors are worlds apart from managing a cold chain for school meals or ensuring strict allergen segregation for a 3PL client. This is where a practical, boots-on-the-ground mindset for change really matters.

Forget chasing industry buzzwords. This journey starts with getting crystal clear on where you stand today. It’s about moving past abstract goals and digging into the concrete realities of your warehouse floor. Think of this foundational stage less as a revolutionary overhaul and more as establishing a clear, data-informed baseline of your current performance.

Building Your Foundation For Process Excellence

Identifying Your Core Key Performance Indicators

The first move in building this foundation is picking the right Key Performance Indicators (KPIs). These metrics are the vital signs of your operation. They tell you exactly where you stand and point directly to the areas ripe for improvement. Without them, any attempt at process improvement is just guesswork.

For food-grade and programmatic operations, your KPIs absolutely must reflect efficiency, quality, and compliance. I've found that a handful of metrics give you the most bang for your buck:

- Overall Equipment Effectiveness (OEE): This is a powerhouse metric for measuring the real performance of your automated packing lines. It rolls up availability, performance, and quality into one simple score.

- Order Fill Rate: What percentage of your orders are shipped completely and on time? A low fill rate is a direct hit to client satisfaction and program success.

- Cold-Chain Compliance: If you're handling perishables like milk for CACFP kits, this is completely non-negotiable. It tracks the percentage of shipments that held the required temperature all the way to the final destination.

- Inventory Accuracy: This measures the gap between what your system says you have and what's actually on the shelves. Inaccurate inventory is a recipe for stockouts, delays, and wasted resources.

The cost to fix a problem once it reaches a customer is exponentially higher than the cost to fix its root cause. By tracking the right KPIs, you shift from a reactive mindset of fixing defects to a proactive strategy of preventing them entirely.

Shifting From Generic Goals to Specific Outcomes

Once you have your core metrics locked in, you can start translating those broad ambitions into tangible objectives. "Improving efficiency" is way too vague to be useful.

A much better goal is, "Increase kits-per-labor-hour by 15% within the next quarter by redesigning our packing station layout." See the difference? This approach connects every single improvement initiative directly to a measurable business outcome.

For a food bank manager, this might mean slashing the time volunteers spend walking between component bins. For a CPG brand vetting a new logistics partner, it means setting clear, non-negotiable expectations for order accuracy and on-time delivery rates. This initial groundwork—defining success with hard numbers—is the essential starting point for any meaningful and sustainable process improvement strategy. It's the roadmap you need to guide every decision that follows.

Mapping Your Workflow To Reveal Hidden Inefficiencies

You can't fix what you can't see.

That’s the simple but powerful idea behind Value Stream Mapping (VSM), a cornerstone tool for any serious process improvement effort. A VSM forces you to pull back from the day-to-day grind and visualize every single action, from the moment raw materials hit your dock to the second a finished product heads out the door.

For programmatic work like food kitting, this isn’t just a theoretical exercise. It's a hands-on way to expose the hidden friction points that burn through resources, slow down delivery, and open the door for errors. The goal is to create a crystal-clear "current state" map that shows you exactly what’s working and, more importantly, where things are breaking down.

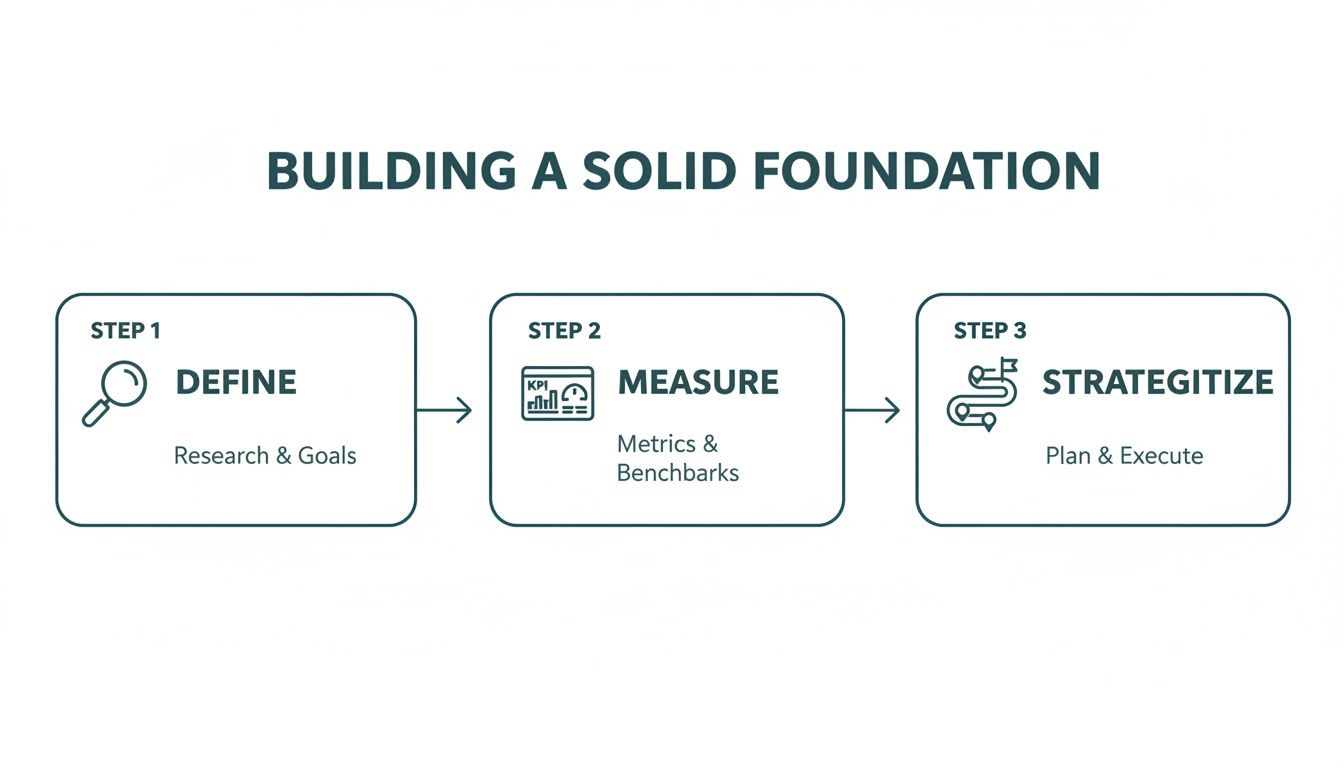

This process lays a simple but critical foundation for improvement by defining your goals, measuring performance, and then building a strategy.

As the diagram shows, without a clear definition of the process and solid metrics, any strategy is just guesswork.

Creating Your First Value Stream Map

You don’t need fancy software to get started. All it really takes is a big whiteboard, a pile of sticky notes, and the right people from your team in the room.

The most critical part? You have to physically walk the process. Lean practitioners call this a "Gemba walk." It means you document each step as it actually happens, not as the SOP says it should happen or how you think it happens.

Let's use a real-world example: assembling a "food-is-medicine" box for a managed care partner. Imagine this box has shelf-stable items, fresh produce, and some educational pamphlets.

Your map would start with things like:

- Component Receiving: How long does it take to unload pallets, verify the manifest, and move goods into quarantine? Write it down.

- QA Inspection: Document the time spent inspecting produce quality and checking expiration dates. Is there a consistent bottleneck here?

- Kitting Line Setup: Measure how long it takes to stage all the necessary components for the assembly line.

- Assembly: Time the cycle time for each station. How long does it take one person to complete their specific task for a single box?

- Final QA & Sealing: Note the time for a final accuracy check, adding cold packs, and sealing the box for shipment.

- Staging & Shipping: Track the time from when a box is sealed to when it’s loaded onto the delivery vehicle.

By documenting every step in this excruciating detail, you’ll reveal the total lead time—giving you a hard number to beat.

Distinguishing Value From Waste

As you build out your map, you’ll start categorizing every action into one of three buckets. This is where the real "aha!" moments happen, because it forces you to see the process through your customer's eyes.

- Value-Added Activities: These are the steps the client (like a healthcare plan) is actually paying for. In our kitting example, this is basically just accurately picking items and packing the box. It's almost always a shockingly small part of the total time.

- Necessary, Non-Value-Added Activities: These are tasks that don't add direct value but are required for compliance or safety. Think temperature checks for cold-chain integrity or documenting lot numbers for traceability. You can't just eliminate them, but you can find ways to make them faster and less disruptive.

- Pure Waste (Muda): This is everything else. It’s the time spent walking across the warehouse to find a tape gun, waiting for more produce to arrive at the line, or reworking a kit because of a packing error. This is your primary target.

A common mistake is trying to optimize a necessary but non-value-added task before asking if it can be simplified or combined with another step. Always go after the pure waste first—it’s the lowest-hanging fruit and delivers the quickest wins.

When you visually separate these activities on your map—maybe with different colored sticky notes—it becomes painfully obvious where your team’s effort is going. You'll see that a few minutes of actual "value-added" assembly are surrounded by hours of non-value-added movement, waiting, and inspection.

This powerful visual lays the groundwork for targeted, high-impact improvements. It also provides a clear framework for discussing the importance of efficient workflows in specialized areas, such as the design and execution of nutrition-focused kitting programs for community health. This clarity is the essential first step toward building a leaner, more effective operation.

Applying Lean And Six Sigma Tools For Targeted Results

Your Value Stream Map has done its job—it's pulled back the curtain on all the hidden friction points in your workflow. You now have a concrete list of what’s holding you back. The next move is to bring in the right methodologies to fix these specific problems. This isn't about blindly adopting a rigid system; it’s about having a toolbox full of proven solutions and picking the right tool for the job.

Methodologies like Lean and Six Sigma are absolute powerhouses for creating change that actually sticks. Lean is all about a relentless focus on getting rid of waste and making things flow better. Six Sigma, on the other hand, is laser-focused on crushing process variation and stamping out defects. When you use them together, there isn't an operational challenge you can't tackle.

Driving Small Wins With Kaizen

One of the most powerful and easy-to-implement principles from the Lean world is Kaizen, which simply means "continuous improvement." Forget waiting around for a massive, disruptive overhaul. Kaizen is about making small, smart, incremental changes every single day.

This approach is perfect for getting your frontline staff and volunteers involved. For instance, a food bank manager could huddle up the team for a quick Kaizen event to brainstorm ways to improve their packing stations. The solution might be as simple as moving the most-used items closer or reorganizing component bins, but these tiny tweaks add up to huge gains in kits-per-hour and way less volunteer fatigue.

The real magic of Kaizen is that it empowers the people who actually do the work. They're the ones who see the problems up close, and they almost always have the most practical ideas for how to fix them.

Tackling Complex Issues With The Six Sigma DMAIC Framework

For those bigger, more stubborn problems, the DMAIC framework from Six Sigma gives you a structured, data-driven roadmap to a real solution. DMAIC stands for Define, Measure, Analyze, Improve, and Control. It’s a systematic method that forces you to find the root cause before you even think about implementing a fix.

Let's see how this works in a real-world programmatic food operation:

- Define: The problem is a high error rate (4%) in senior meal boxes—specifically, low-sodium items are frequently missing. This is a big deal, as it puts participant health and contract compliance at risk.

- Measure: For a full month, you collect data. You track the types of errors, when they happen, and which packing lines are the culprits. You confirm the 4% error rate and discover that most mistakes occur right around shift changes.

- Analyze: You get the team together and use a tool like a fishbone diagram to dig into potential root causes. The top contenders? Poor communication during handoffs, confusing bin labels, and no consistent verification process.

- Improve: The team decides to pilot a solution on just one line. They introduce a standardized checklist for every shift handoff, implement color-coded labels for special dietary items, and add a mandatory two-person verification check for every 50th box.

- Control: The pilot is a huge success, dropping the error rate to below 0.5%. Now, you roll out the new SOPs to every line, update all the training guides, and keep a close eye on the metric to make sure the improvement sticks.

By sticking to the DMAIC process, you’re not just putting a bandage on the symptoms—you’re surgically removing the root cause. This is what stops the same old problems from creeping back in a few months down the road.

When applied thoughtfully, both Lean and Six Sigma offer powerful ways to drive meaningful change. The table below illustrates how each methodology can address common hurdles in food logistics, helping you choose the best approach for your specific challenge.

Lean vs. Six Sigma Application In Food Logistics

| Challenge | Lean Approach (Focus on Flow & Waste) | Six Sigma Approach (Focus on Variation & Defects) | Real-World Example |

|---|---|---|---|

| Long Kitting Changeover Times | Apply SMED principles to analyze and reduce setup time. Convert internal setup steps (line stopped) to external ones (line running). | Analyze changeover time data to identify sources of variation and standardize the most efficient procedures across all teams. | Pre-staging components for the next kit run while the current one is still active, slashing downtime from 45 to 15 minutes. |

| High Error Rate in Meal Boxes | Use Poka-Yoke (mistake-proofing) like color-coded bins for allergens or designing workstations where the wrong component simply won’t fit. | Use the DMAIC cycle to statistically identify the root cause of errors (e.g., a specific shift, a confusing label) and implement a controlled solution. | A food bank realizes 70% of errors are due to a confusing label on two similar-looking grain packets and redesigns the packaging. |

| Inefficient Warehouse Layout | Conduct a "spaghetti diagram" exercise to visually map worker movement. Reorganize inventory based on frequency of use (ABC analysis) to minimize travel time. | Collect data on pick times and distances to identify statistically significant bottlenecks. Use data to justify a new, optimized warehouse layout. | A 3PL moves high-volume items for a holiday kit closer to the packing lines, reducing worker travel by 30% and boosting throughput. |

| Inconsistent Cold Chain Adherence | Implement visual management tools like color-coded temperature indicators on pallets and standardized checklists for loading refrigerated trucks to ensure flow. | Analyze temperature log data to find patterns of deviation. Use statistical process control (SPC) charts to monitor temps in real-time and alert staff to anomalies. | A distributor finds that temperatures spike during a specific 30-minute loading window and implements a new pre-chilling SOP for their staging area. |

Ultimately, choosing between Lean and Six Sigma—or combining them—depends on whether your primary goal is to eliminate waste and improve speed (Lean) or to reduce defects and variability (Six Sigma).

Speeding Up Changeovers With SMED

Another killer tool from the Lean arsenal is Single-Minute Exchange of Die (SMED). Don't let the clunky manufacturing name fool you; the concept is brilliantly simple: drastically cut the downtime it takes to switch from making one thing to making another.

For any 3PL or kitting operation, this is a game-changer. Think about your team having to switch from packing family nutrition kits to assembling specialized "food-is-medicine" boxes for a healthcare partner. That changeover involves clearing the line, hauling in new components, changing signage, and briefing the team on completely new packing rules. It's all downtime.

SMED provides a framework for analyzing every single step of that changeover. You sort tasks into two buckets: things that can only be done when the line is stopped ("internal" setup) and things that can be done beforehand ("external" setup). The goal is to convert as many internal steps to external ones as possible, effectively erasing non-productive time.

With SMED, an operation could realistically take a 45-minute changeover and crush it down to less than 15 minutes. That adds hours of productive capacity back into every single week. This kind of strategic operational thinking is what separates the leaders from the rest, and you can explore more of these concepts in our thought leadership content.

Using Technology To Drive Next-Generation Efficiency

Methodologies and frameworks are foundational, but let's be real—modern manufacturing process improvement is turbocharged by technology. In the world of food logistics, where margins are razor-thin and compliance is everything, integrating the right tech isn't just a "nice-to-have." It's how you build a resilient, scalable operation that can keep up.

Tools like the Internet of Things (IoT), artificial intelligence (AI), and digital twins aren't just buzzwords anymore. They're solving real-world headaches on the warehouse floor, moving from theory to practical application. These technologies do more than just nudge your metrics; they offer entirely new ways to see, understand, and fine-tune incredibly complex workflows.

Preventing Downtime With Predictive Maintenance

In food distribution, equipment failure can be a full-blown catastrophe. Just imagine a refrigeration unit dying in a warehouse packed with multi-day meal kits for a CACFP sponsor. You're looking at massive product loss, a serious food safety risk, and a huge blow to your reputation. This is exactly where predictive maintenance, powered by IoT sensors and AI, becomes a total game-changer.

Instead of just reacting to breakdowns, IoT sensors constantly monitor the health of your critical equipment—compressors, fans, motors—by tracking variables like temperature, vibration, and energy consumption. All that data is fed into an AI model that learns the machine's normal "heartbeat."

From there, the system can spot anomalies and predict a potential failure weeks before it happens, flagging it for maintenance long before it grinds your operation to a halt. It’s a proactive strategy that keeps the cold chain secure and your promises intact.

Streamlining Operations With WMS And EDI Integration

As you scale up, especially when you bring a third-party logistics (3PL) partner into the mix, manual processes quickly become a crippling bottleneck. Integrating your Warehouse Management System (WMS) with Electronic Data Interchange (EDI) is one of the most fundamental steps you can take toward operational excellence.

This integration automates the flow of information between you, your suppliers, and your clients, creating a single source of truth. Here's what that looks like in the real world:

- Automated Order Processing: An order placed by a client flows directly into your WMS via EDI. No more manual data entry, no more costly human errors.

- Real-Time Inventory Visibility: Inventory levels update automatically across every system, giving you and your partners an accurate, live view of exactly what’s on the shelves.

- Faster, More Accurate Shipping: The WMS generates pick lists, packing slips, and shipping labels on its own, ensuring the right orders get out the door correctly and on time.

For anyone managing complex kitting projects or high-volume fulfillment, this level of automation isn't optional. It’s the very backbone of an efficient, error-free operation. At the core of modern efficiency is solid automation; check out this guide to industrial controls automation to see how these systems are put together.

Simulating The Future With Digital Twins

The idea of a "digital twin" might sound like something out of a sci-fi movie, but it's an incredibly practical tool for process improvement. A digital twin is a virtual, dynamic model of a physical process, a piece of equipment, or even your entire warehouse. It gives you a risk-free sandbox to test changes and run "what-if" scenarios.

Think about organizing a large-scale kitting event with volunteers. Instead of just guessing at the best layout for packing stations, you could use a digital twin to simulate different setups. You could model the flow of people and materials to pinpoint bottlenecks and figure out the most efficient configuration before a single volunteer even shows up.

Or take a more complex challenge, like planning a disaster response shipment. A digital twin lets you model different logistics scenarios, factoring in variables like road closures, truck capacity, and delivery schedules to map out the most effective response strategy. These powerful simulation tools are just one example of the advanced logistics solutions that technology now offers. By using them, you shift from reactive problem-solving to proactive, data-driven optimization—building a truly forward-thinking and resilient operation.

Making Sure Your Improvements Stick: Compliance and Change Management

You can chase operational gains all day, but they mean absolutely nothing if they put you on the wrong side of compliance. Every single efficiency you introduce has to be built on a rock-solid foundation of regulatory and safety protocols. This is where the world of manufacturing process improvement has to seamlessly merge with rigorous, detail-oriented oversight.

In food logistics, the stakes couldn't be higher. A new kitting process that doubles throughput but compromises allergen segregation isn't an improvement; it's a critical failure waiting to happen. In the same way, a workflow tweak that overlooks Buy American provisions could instantly jeopardize a major government contract.

To successfully embed process changes, you need to keep two things in focus at all times: the technical and regulatory details on one hand, and the people who will execute those changes day in and day out on the other.

Weaving Compliance Into Your Process DNA

Compliance can't be an afterthought you check off at the end. It has to be baked into the improvement design process from the moment you start. When you map out a new workflow, you must simultaneously map out all its compliance touchpoints.

Think of it this way: for every step in a process, there's a corresponding compliance requirement.

- Receiving Raw Goods? That immediately triggers protocols for supplier verification, lot number tracking, and initial QA checks.

- Setting Up a Kitting Line? This demands documented procedures for allergen segregation, ensuring dairy, nuts, or gluten are handled in designated zones with specific, separate equipment.

- Storing Finished Kits? Cold chain integrity is everything. That means validated SOPs for temperature monitoring, data logging, and immediate corrective actions if a deviation occurs.

For businesses in high-risk sectors like manufacturing, tying your system to established standards is non-negotiable. Pursuing something like ISO 45001 certification for manufacturing is crucial for building a truly robust management system. It ensures safety and quality aren't just goals, but are systematically managed and verified.

A common pitfall is viewing compliance as a barrier to speed. The reality is that well-designed, compliant processes are faster and more reliable because they eliminate the rework, waste, and catastrophic risks that come from cutting corners.

Managing The Human Side Of Change

You can design the most brilliant, efficient, and compliant process on paper, but if your team doesn't buy in and adopt it, it's completely worthless. The human element is the most critical—and often the most overlooked—part of any process improvement initiative. This is where a real change management strategy becomes essential.

Resistance to change is just human nature. It comes from uncertainty, fear of the unknown, or a feeling of losing control over a job someone has done the same way for years. Your job is to replace that uncertainty with clear communication and confidence.

Start by explaining the "why." Don't just announce a new SOP is coming. Show the team the Value Stream Map. Point out the exact bottlenecks and frustrations the new process is designed to eliminate. When people understand the purpose behind the change, they are far more likely to get on board.

Building A Culture Of Continuous Improvement

True, lasting change isn't a one-time project; it's a cultural shift. The real goal is to move from top-down mandates to a bottom-up movement where everyone on the floor feels empowered to identify and suggest improvements.

This doesn't just happen on its own. It requires a few key things:

- Hands-On Training: Don't just send an email. Provide comprehensive, hands-on training for any new process or technology. Make sure every team member feels competent and supported as they learn.

- Open Feedback Loops: Create simple, accessible channels for staff to voice concerns, ask questions, and offer suggestions about the new workflow. A suggestion box, a quick weekly huddle, or a dedicated digital channel can work wonders.

- Celebrate Small Wins: When a team successfully implements a change that moves a KPI in the right direction, celebrate it. Publicly. This recognition reinforces the value of their effort and builds momentum for whatever comes next.

By integrating rigorous compliance checks with a thoughtful change management plan, you ensure your process improvements are not only effective but also sustainable and safe. It’s this dual approach that truly transforms an operation, creating a resilient system where efficiency and quality go hand in hand.

Common Questions from the Field

When you're trying to improve manufacturing processes in the world of programmatic food logistics, a lot of questions come up. It's only natural. We hear similar things from program managers, operations leads, and procurement specialists who are all wrestling with the same kinds of hurdles.

These aren't just theoretical questions. They get right to the heart of the real-world challenges you face every day—from trying to fund a project to making sure the people on the floor are actually on board with the changes.

How Do We Start With A Limited Budget?

This is probably the most common reality we see. But a tight budget doesn't have to be a roadblock; it just means you have to be smarter about where you start. The goal is to find low-cost, high-impact changes that build momentum and prove the concept.

Start with a "Gemba walk." This is just the simple act of getting out on the warehouse floor and watching the work happen. It costs nothing but your time, and I guarantee you'll immediately spot major inefficiencies that are completely invisible from behind a desk. Another fantastic, low-cost tool is a whiteboard. Grab your team and draw a Value Stream Map together to visualize waste without needing any fancy software.

From there, you can focus on a few simple changes:

- Kaizen Events: These are all about small, continuous improvements. For instance, just reorganizing a kitting station to cut down on how far volunteers need to walk can dramatically increase your kits-per-hour rate without spending a dime.

- Implement 5S: The principles—Sort, Set in Order, Shine, Standardize, and Sustain—are absolutely foundational. An organized workspace is a more efficient and safer workspace, and getting there is mostly a matter of focused, structured effort.

These early activities create real momentum and often generate the very savings you can use to fund bigger projects down the road.

What Are The Most Important KPIs For A Food Kitting Operation?

For any food kitting program, your Key Performance Indicators (KPIs) need to give you a crystal-clear picture of efficiency, quality, and compliance. You could track a hundred different things, but focusing on a handful of vital metrics will give you the most actionable information.

If I had to choose, these five are essential:

- Order Fill Rate: This is the gold standard—the percentage of orders you complete accurately and deliver on time. It's a direct measure of how well you're meeting your programmatic promises.

- Kits Per Labor Hour: This is your core efficiency metric. It tells you how productive your packing lines are and helps you accurately forecast how much labor you'll need for the next big project.

- Inventory Accuracy: When you're dealing with specific SKUs for dietary needs, knowing exactly what you have is non-negotiable. Your goal here should always be 99% or higher.

- Cold Chain Compliance Rate: If you have kits with perishables like milk or fresh produce, this is critical. It measures the percentage of shipments that stayed within the required temperature range all the way from your warehouse to the final drop-off.

- Picking & Packing Accuracy: This tracks errors like wrong items or missing items. For allergen-sensitive or diet-specific food-is-medicine programs, this isn't just a quality metric—it's a safety metric.

How Can We Ensure Buy-In From Staff And Volunteers?

Getting your team to buy into changes really comes down to two things: involvement and communication. It’s human nature—people support what they help create.

You have to involve the people actually doing the work. Bring your frontline staff and your most committed volunteers into your Value Stream Mapping sessions and Kaizen events. They have insights from the ground that managers will always miss. They know what's frustrating, what's slow, and what could be done better.

When people feel heard and see their own ideas put into action, they shift from being passive participants to being true champions for the change. That kind of grassroots support is far more powerful than any top-down directive.

Always be clear about the "why" behind any change. Explain how a new process makes their job easier, safer, or allows them to make a bigger impact on the community you serve. Celebrate the small wins publicly to build positive energy, provide excellent hands-on training, and make sure there’s an open feedback loop where people can share concerns without feeling judged.

At Umoja Health, we don't just supply food. We provide complete programmatic and logistics solutions that are grounded in the principles of continuous improvement. From designing volunteer-friendly kitting SOPs to implementing compliant cold-chain protocols, we help partners like you achieve true operational excellence.

Discover how our expertise can support your mission at https://umojahealth.com.