A digital transformation roadmap is your strategic playbook. It’s the document that spells out the why, what, how, and when behind your shift to a digital-first operation. This isn't just about buying new software; it’s a detailed guide to get your technology, processes, and people all pulling in the same direction toward clear business goals. The whole point is to make sure every dollar and hour you invest delivers real, measurable value.

Laying the Groundwork for Your Digital Transformation

Before you can build a new digital future, you need a brutally honest assessment of where you stand today. A successful digital transformation roadmap doesn't start with chasing the latest tech fad. It begins with a clear-eyed look at your organization's digital maturity.

This foundational step is non-negotiable for anyone, whether you're a CPG leader shifting to a food-grade 3PL or a food bank manager planning forward-buys. To get started, it helps to have a solid grasp of what digital transformation entails. This frames your assessment around business outcomes, not just flashy tech projects.

Assessing Your Digital Maturity

A thorough self-assessment is what saves you from the classic mistake of buying 'tech for tech's sake.' It forces you to take a hard look at four critical pillars: leadership buy-in, team culture, existing technology, and employee skill sets. This process quickly shines a light on your biggest gaps and highest-impact opportunities, ensuring your first moves are smart ones.

Let's be real about these initiatives—only 35% of digital transformation projects actually hit their targets. That high failure rate usually comes from misaligned strategies and a total failure to gauge readiness beforehand. For companies managing complex supply chains—like shipping shelf-stable foods nationwide or running FDA-registered 3PLs with EDI/WMS for Nutrition Security kits—this maturity check is your first line of defense against becoming another statistic.

A roadmap built on a weak foundation is a blueprint for failure. You wouldn't build a warehouse on uneven ground, and the same principle applies here. An honest look at your current state is the most critical investment you can make.

The Four Pillars of Readiness

To build your roadmap, you have to evaluate each of these areas to establish a firm baseline. A great way to structure this is by using a self-assessment framework to see where you land on the spectrum from beginner to advanced.

Take a look at this framework. It helps you honestly evaluate your organization's current state across the four key pillars of readiness.

Digital Maturity Self-Assessment Framework

| Assessment Pillar | Beginner Level (What this looks like) | Intermediate Level (What this looks like) | Advanced Level (What this looks like) |

|---|---|---|---|

| Leadership & Vision | Digital initiatives are siloed and lack a clear, unified vision from the top. | Leadership supports digital projects, but there isn't a single, cohesive strategy. | A clear digital vision is championed by the C-suite and integrated into all business goals. |

| Culture & People | The team is resistant to change; new tools are seen as a burden. | Some teams are open to new tech, but adoption is inconsistent and lacks enthusiasm. | The entire organization embraces change, actively seeking new tools and process improvements. |

| Technology & Systems | Systems are outdated and disconnected. Data is stuck in silos (e.g., separate WMS and EDI). | Some systems are integrated, but manual workarounds are still common to connect key data. | A fully integrated tech stack (e.g., seamless EDI/WMS) provides a single source of truth. |

| Skills & Capabilities | The team lacks the basic digital literacy needed for new systems. Training is an afterthought. | Key individuals have strong digital skills, but there are significant gaps across the broader team. | The organization invests in continuous training and upskilling, fostering widespread digital fluency. |

By working through this assessment, you get a much clearer picture of your strengths and, more importantly, the areas that need immediate attention before you invest in any new technology.

For example, an organization like Unidad Logistics uses its deeply integrated EDI/WMS capabilities to manage incredibly complex kitting and multi-pack workflows. You can see their advanced approach at https://umojahealth.com/unidad-logistics/. They didn't get there overnight. It started with a thorough assessment of their systems and a real commitment to closing the tech gaps that mattered most to their food-grade 3PL clients.

Evaluating these four pillars gives you a detailed, factual starting point. From that baseline, you can build a practical and achievable roadmap that solves real-world problems—like streamlining SOPs for senior food boxes or getting better inventory visibility for culturally specific foods—and delivers genuine value from day one.

Defining Your Goals and Prioritizing What Matters

After taking a brutally honest look at where you stand, the next move in building your digital transformation roadmap is figuring out where you’re headed. A vague goal like "be more digital" is a fast track to wasted money and failed projects. Real success comes from tying every single digital initiative to a specific, tangible program need that solves a real problem.

For example, a state SFSP administrator might need to develop compliant home-delivery kits to meet the new Rural Non-Congregate guidance. A Managed Medicaid director might be focused on launching a 12-week diabetes grocery program that needs bulletproof outcomes reporting to prove its worth. These aren't abstract tech goals—they are program-first objectives that technology is meant to serve.

This mindset completely changes the conversation from "what software should we buy?" to "what operational headaches can we eliminate?" It’s all about translating your organization's high-level vision into concrete objectives your team can actually get done.

From Big Ideas to Actionable Initiatives

So, how do you bridge the gap between that big-picture strategy and what your team does day-to-day? You need a practical way to turn broad goals into a prioritized list of projects. This is where you connect the "why" with the "what" and the "how."

Start by getting stakeholders in a room—people from every corner of your operation, from the warehouse floor to program compliance. The goal is to brainstorm a master list of potential initiatives.

Encourage everyone to think big and small. Nothing is off the table at this stage. You might end up with ideas like:

- Developing an EDI/WMS checklist for allergen-segregated storage to stop cross-contamination.

- Automating pack lists for 500 different CACFP sites to slash manual errors.

- Piloting a WIC home delivery workflow with inventory-aware substitutions built-in.

- Creating a new reporting dashboard for Food-is-Medicine program outcomes.

Once you have this raw list, the real work begins. You can’t do everything at once. Trying to is a recipe for burnout and failure. You have to prioritize.

Prioritizing with the Impact/Effort Matrix

A simple but incredibly powerful tool for this is the Impact/Effort Matrix. This framework helps you visually sort your ideas so you know what to tackle now, what to plan for later, and what to ignore completely. It forces you to weigh each initiative against two core criteria: its potential value (Impact) and the resources needed to pull it off (Effort).

You can map every initiative into one of four quadrants:

| Quadrant | Description | Example Initiative for Food Programs |

|---|---|---|

| High Impact / Low Effort | Quick Wins: These are your top priorities. They deliver huge value for minimal resources, building momentum and proving the roadmap’s value from day one. | Implementing a standardized digital checklist for receiving Buy American compliant products. |

| High Impact / High Effort | Major Projects: These are the big, strategic moves. They offer massive rewards but require serious planning and investment. | Integrating a new WMS across three warehouses to provide real-time inventory visibility. |

| Low Impact / Low Effort | Fill-Ins: These are nice-to-haves. You can knock them out when you have spare time, but they shouldn’t distract from the main event. | Creating a new color-coding system for internal shared drive folders. |

| Low Impact / High Effort | Time Sinks: Just avoid these. They chew up valuable resources for almost no meaningful return. | Building a custom social media platform for internal team communication. |

Focusing on "Quick Wins" first is a game-changer. These early successes build crucial buy-in from leadership and frontline staff, creating the political and cultural capital needed to tackle the larger, more complex "Major Projects" down the line.

This structured approach turns a messy wish list into a clear, sequenced plan. It ensures your digital transformation roadmap is both ambitious and achievable, focusing your energy on changes that solve the most pressing problems for your participants, partners, and stakeholders. That clarity is what separates a roadmap that gathers dust on a shelf from one that actually drives progress.

Building Your Technology and Integration Checklist

Once your goals are set and prioritized, your digital transformation roadmap has to get down to brass tacks. It's time to shift from the "what" to the "how." While technology is the engine for all this change, its real power comes from smart integration, not just a collection of flashy, disconnected tools that end up creating more problems—and data silos—than they solve.

This is where you build the technical blueprint for your operation. We’re moving from high-level ambitions to the nuts and bolts of your tech stack, aiming for a seamless ecosystem where data flows freely. That’s what enables smarter, faster decisions for everyone, from a warehouse manager on the floor to a program director reviewing KPIs.

Vetting Technology Partners and Core Systems

Choosing the right technology isn't about finding the most advanced software on the market; it's about finding the right fit for your specific operational reality. A generic Warehouse Management System (WMS) might work wonders for a standard e-commerce business, but it could completely buckle under the complexities of a food program.

Your evaluation checklist has to be laser-focused on the unique demands of food logistics and program compliance. As you assess potential partners or new systems, zero in on these critical capabilities:

- Complex Kitting and Multi-Pack Workflows: Can the system's EDI/WMS actually handle the intricate assembly instructions for an SFSP multi-day kit or a Food-is-Medicine grocery box? Don't just ask—demand a live demo using one of your most complicated pack-outs.

- Compliance and Traceability: Does the technology truly support lot tracking and recall management down to the individual unit? Critically, can it flag and segregate products to ensure Buy American compliance for your federal programs?

- Cold-Chain Management: If you're a CACFP sponsor shipping milk or other refrigerated items, does the system integrate with temperature monitoring devices? Can it trigger real-time alerts if a shipment deviates from its required temperature range?

Don't just take a sales pitch at face value. A truly capable partner can demonstrate how their system handles your most challenging edge cases, not just the easy, everyday tasks. If they can't show you, they can't do it.

Crafting a Data Integration Strategy

A solid integration strategy is what transforms a pile of separate applications into a single, intelligent platform. The ultimate prize here is a single source of truth for all your operational data. This is what finally eliminates the guesswork and endless manual reconciliation that plagues so many organizations.

A single source of truth means the inventory data in your WMS perfectly matches what your program portal shows—no exceptions. It means when a specific item for a WIC participant's order is out of stock, the system can automatically suggest a compliant, inventory-aware substitution without anyone needing to lift a finger. This is where you can explore advanced platforms that provide the connective tissue for your entire operation, similar to how the Umoja Health uCloud platform integrates various program and logistics functions.

To get there, you need to map out every key integration point. Think about how data needs to move between systems to automate decisions and give everyone the visibility they need.

Here’s a look at the critical integration points you should be planning for. A setup like this ensures that every piece of your operation—from the warehouse floor to the accounting department—is working off the same, up-to-the-minute information.

Key Technology Integration Points for Food Programs

| System/Process | Integration Point | Key Requirement Example | Target Program |

|---|---|---|---|

| WMS | ERP/Accounting | Automatically sync inventory receipts and shipments to generate invoices and update financial records without manual data entry. | All Programs |

| EDI | Partner Portals | Pull participant orders directly from a healthcare plan's portal into the WMS for fulfillment, eliminating manual order entry. | Food-is-Medicine |

| Program Portal | Inventory System | Provide real-time stock levels to participants during online ordering, preventing orders for out-of-stock items. | WIC Home Delivery |

| WMS | Reporting Dashboard | Feed live fulfillment data (e.g., kits packed per hour, order accuracy) into an executive dashboard for performance tracking. | SFSP/CACFP |

Getting this right doesn't just solve today's problems; it prepares you for tomorrow's challenges and opens the door to more advanced applications.

Think about how other industries apply this thinking. In healthcare, edge computing allows for real-time ICU monitoring to speed up diagnostics. You can apply that same logic to Disaster Response logistics when comparing self-heating meals versus ready-to-eat options for first-72-hour load plans. Financial services use AI virtual agents to field thousands of real-time queries—a model a CACFP operations lead could use to automate pack lists across 500 sites. This forward-thinking approach ensures your technology stack is built not just for now, but for what's next.

Executing Your Roadmap with Agility and Team Alignment

A brilliant digital transformation roadmap is just a nice document until you put it into action. Forget the old-school, rigid project plans that span multiple years and can't adapt to change. Modern digital transformation thrives on agile execution, breaking down huge goals into smaller, manageable sprints that deliver real value, fast.

This approach keeps your team focused and motivated. Instead of waiting years to see the results of a massive overhaul, you get to celebrate wins every few weeks. This iterative process allows you to learn and pivot, which is absolutely essential in the ever-shifting world of food programs and logistics.

Breaking Down Goals into Actionable Sprints

The heart of agile execution is taking a large, high-effort project from your roadmap and slicing it into bite-sized pieces. Each piece, or "sprint," is a short, time-boxed effort aimed at producing a specific, tangible outcome.

Let's say a major strategic goal is to "Launch a fully compliant WIC home delivery pilot program." Trying to tackle that all at once is just overwhelming. A much smarter way is to break it down into focused sprints:

- Sprint 1 (2 Weeks): Goal: Map the end-to-end WIC participant ordering workflow. Tasks: Interview three state vendor managers, document current JPMA process flows, and pinpoint the top five technical bottlenecks.

- Sprint 2 (3 Weeks): Goal: Develop a prototype for an inventory-aware substitution feature. Tasks: Define substitution logic for common WIC items, build a low-fidelity UI, and get feedback from a WIC participant focus group.

- Sprint 3 (4 Weeks): Goal: Pilot the home delivery packing process for 20 orders. Tasks: Create digital pack lists, test cold-chain protocols for milk, and measure pack-out accuracy and time.

This method makes progress visible and measurable, turning an intimidating project into a series of achievable steps.

Aligning Your Team with a RACI Chart

Of course, agile sprints only work if everyone knows exactly what they're supposed to be doing. This is where a RACI chart becomes your best friend. RACI stands for Responsible, Accountable, Consulted, and Informed, a simple but powerful framework for clarifying roles and responsibilities.

Miscommunication can derail even the best-laid plans, especially when you're navigating complex compliance landscapes with multiple stakeholders. A good RACI chart cuts through the ambiguity, ensuring tasks don’t fall through the cracks.

A project without clear roles is like a kitchen with too many chefs and no one washing the dishes. A RACI chart ensures every task has an owner, preventing chaos and keeping the entire project moving forward smoothly.

Let's apply this to our "WIC Home Delivery Pilot" example. A RACI chart here would clearly define who does what, creating seamless collaboration between state agencies, tech partners, and logistics teams. To manage a project this multifaceted, you need a deep understanding of your team's structure and capabilities, which you can learn more about by exploring how high-performing teams are organized.

| Task/Decision | State WIC Director | 3PL Operations Manager | IT Project Manager | CBO Partner Lead |

|---|---|---|---|---|

| Define Substitution Rules | Accountable | Consulted | Responsible | Informed |

| Test Packing Workflow | Informed | Accountable | Consulted | Responsible |

| Approve Participant UX | Accountable | Informed | Responsible | Consulted |

| Report on Pilot Metrics | Accountable | Responsible | Responsible | Informed |

This simple matrix makes it crystal clear who needs to do the work (Responsible), who has the final say (Accountable), who should provide input (Consulted), and who just needs to be kept in the loop (Informed). It’s an indispensable tool for maintaining alignment across your entire digital transformation roadmap.

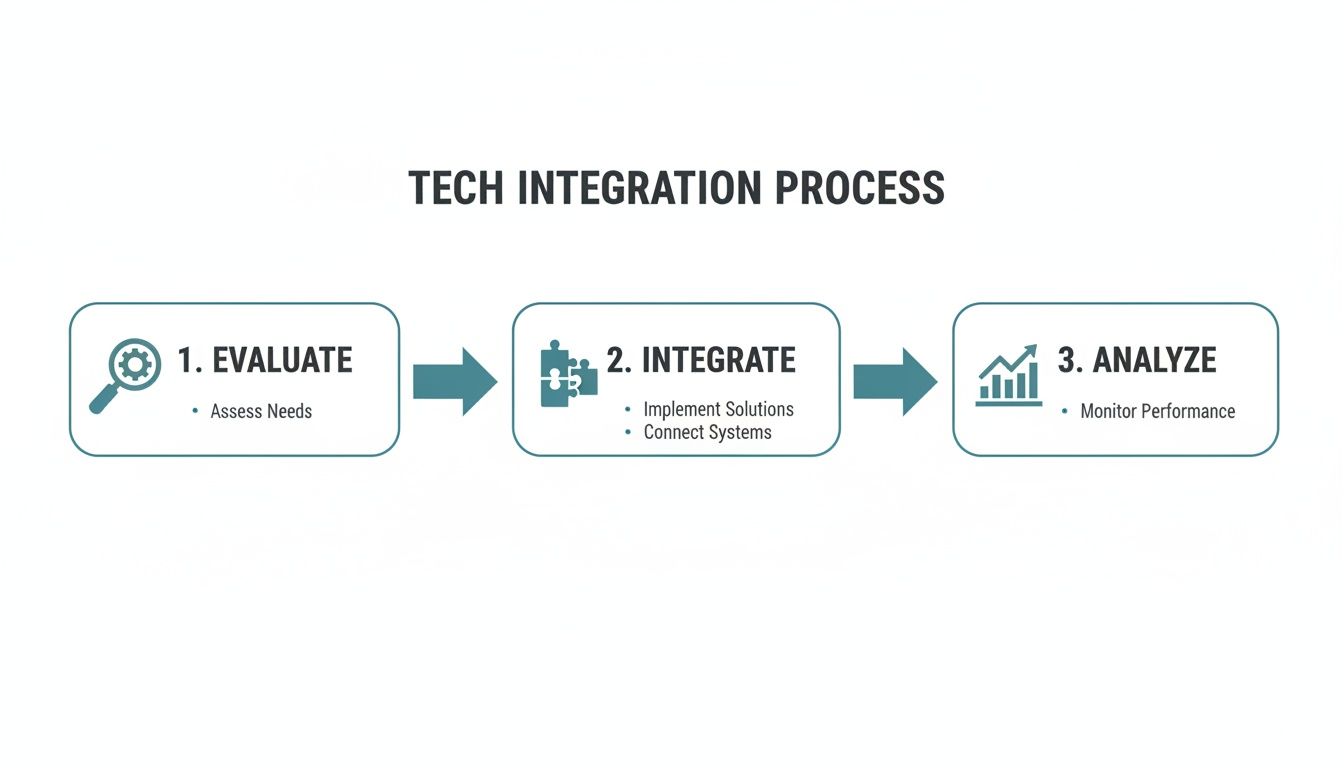

This diagram shows how technology evaluation, integration, and analysis happen iteratively within each sprint.

It’s a great visual reminder that successful execution isn’t a one-time setup. It's a continuous cycle, ensuring that each step builds intelligently on the last.

Measuring Success with KPIs That Actually Matter

So, how do you actually prove your digital transformation is working? A digital transformation roadmap is just a plan on paper until you can answer that question with hard numbers. This is where we get into measurement—moving past superficial "vanity metrics" to pin down the Key Performance Indicators (KPIs) that prove you’re hitting your goals and delivering a real return on investment.

Without solid metrics, you're flying blind. You might feel like things are getting better, but you can't prove it to leadership, and you definitely can't make smart, data-backed decisions about what to tackle next. The right KPIs take the guesswork out of the equation, shining a light on what’s working and what isn’t.

From Vague Goals to Tangible Metrics

The trick is to choose KPIs that directly reflect the specific outcomes you defined way back at the start of this journey. Generic metrics are useless here. Your indicators have to be tailored to the unique reality of your food program or 3PL operation.

A logistics operation obsessed with efficiency won't track success the same way a health program focused on participant outcomes will. Each operation needs its own distinct set of vitals to monitor.

-

For a logistics operation: Don’t just track "shipments per day." Get granular with KPIs like Order Fulfillment Accuracy (what percentage of our orders are picked, packed, and shipped without a single error?) or Reduction in Kitting Time (how many seconds have we shaved off assembling a multi-day SFSP meal kit?).

-

For a health program: Simple enrollment numbers don't tell the whole story. Instead, measure things like Participant Engagement Rate (are people actually logging into and using the new portal?) or Time to Generate Compliance Reports (how much faster can we pull the data to prove Buy American compliance for an audit?).

The most powerful KPIs are leading indicators, not lagging ones. A leading indicator, like 'pick-to-pack time,' predicts future success (faster fulfillment), while a lagging one, like 'quarterly revenue,' just reports on what already happened. Focus on the metrics that give you a chance to course-correct in real time.

Tailoring Dashboards for Different Roles

Data is only useful if it’s accessible and relevant to the person looking at it. A one-size-fits-all dashboard just creates noise, overwhelming some people while leaving others starved for the specific information they need. A critical part of a successful digital transformation roadmap is building role-specific dashboards that deliver the right insights to the right people.

This means your warehouse manager and your executive director should see completely different views, even if they're pulling from the same underlying data.

Example KPI Dashboards

| Role | Dashboard Type | Key KPIs Displayed | Purpose |

|---|---|---|---|

| Warehouse Manager | Operational Dashboard | Orders Packed Per Hour, Inventory Accuracy Rate, Dock-to-Stock Time, Kitting Errors by SKU | Provides a real-time, ground-level view to identify and fix immediate operational bottlenecks. |

| Program Director | Strategic Dashboard | Participant Satisfaction Score, Cost Per Meal Served, Compliance Audit Pass Rate, Program Enrollment Growth | Offers a high-level overview of program health, ROI, and alignment with strategic goals. |

This tailored approach is what makes data a practical tool for daily decision-making at every level. The warehouse manager can spot a problem on a specific packing line and get it fixed before lunch. Meanwhile, the director can use that program growth data to justify budget requests for the next fiscal year.

Ultimately, measurement isn't the final step—it's a continuous loop. The insights you pull from your KPIs feed right back into your roadmap, helping you refine priorities, adjust your sprints, and constantly improve. This data-driven cycle is what turns a one-off project into a sustainable culture of innovation, proving the value of your efforts every single day.

Answering the Tough Questions About Your Digital Transformation Roadmap

Kicking off a major strategic shift always brings up a lot of questions, and laying out a digital transformation roadmap is certainly no exception. I've seen countless organizations grapple with the same hurdles when trying to get from the planning stage to actual execution. Tackling these common concerns right from the start is the best way to build clarity and the confidence your team needs to push forward.

Let's dive into some of the most frequent questions that pop up in the food program and logistics world. My goal here is to give you practical, field-tested advice to help you navigate the tricky spots and make solid decisions as you build out your plan.

How Do We Get Leadership Buy-In When Budgets Are Tight?

This is the big one. The secret is to build a rock-solid business case that’s laser-focused on specific, measurable outcomes. Forget about pitching a massive, vague "digital overhaul." That’s a surefire way to get shut down.

Instead, come to the table with a prioritized plan that highlights some clear "quick wins." This shows you can deliver value right out of the gate. For example, you can show how a small, targeted investment in automating pack lists for CACFP kits will cut labor costs by a concrete percentage or boost order accuracy, both of which hit the bottom line directly.

The trick is to frame the investment not as a cost, but as a critical move toward greater efficiency and better compliance. Starting with a smaller pilot project is a fantastic way to prove the ROI and build the momentum you'll need for bigger investments down the line.

Stop asking for a blank check for 'transformation.' Instead, ask for a targeted investment to solve a specific, expensive problem. When you can prove a $50,000 investment will save $150,000 in the first year, the whole conversation changes.

What Is the Biggest Mistake When Integrating a New WMS?

Hands down, the most common mistake is focusing 100% on the technology while completely ignoring the people and processes it's meant to support. A new WMS rollout isn't a tech project; at its core, it's a change management project.

You have to get your end-users—everyone from the warehouse crew to the program administrators—involved from day one. I mean it. Map out their current workflows so you know exactly how the new system will change their day-to-day reality.

Another huge, and surprisingly common, oversight is failing to plan for data migration. Make sure you have clean, accurate data to import, and block out plenty of time for validation and testing before you even think about going live. A technically perfect system will crash and burn if the team isn’t ready for it or the data is a mess.

How Long Should Our Roadmap Be?

Think of your roadmap as a living, breathing document, not some rigid five-year plan carved in stone. Your high-level strategic vision might look out three to five years, but your detailed, actionable plan should zoom in on the next 12-18 months.

Break that shorter-term plan into quarterly goals and even monthly sprints. This kind of agile approach gives you the flexibility to adapt to new technologies, shifting compliance rules (like new SFSP guidance), and what your stakeholders need right now. Make it a habit to review and tweak the roadmap every quarter. This keeps you focused on immediate priorities while making sure you're still heading in the right long-term direction.

At Umoja Health, we live and breathe these complexities every day. From developing compliant home-delivery kits to rolling out robust Food-is-Medicine programs, we bring the food, logistics, and technology needed to make your digital transformation a real success. Learn how we can support your mission.