Process improvement isn't just a corporate buzzword; it’s a structured way to find and fix the things that slow you down, cause mistakes, and waste resources. Frameworks like Lean, Six Sigma, and Kaizen give you a proven roadmap to make your operations faster, sharper, and more cost-effective.

Choosing Your Process Improvement Framework

This is the most important decision you'll make. Picking the right approach from the start is the difference between meaningful, lasting change and a lot of wasted effort. Without a clear framework, improvement initiatives often fizzle out, feel disjointed, and don't deliver the results you need.

The whole point is to match the tool to the job. You have to get to the heart of what's really holding you back, whether you're trying to cut down delivery times at a food bank or guarantee bulletproof compliance in a healthcare program. For mission-driven organizations, this choice is even more critical—every efficiency gain means more people are served.

Diagnosing Your Core Challenge

Before you even think about specific methodologies, you need to play doctor. What’s the biggest pain point for your team? Are you dealing with waste, or is quality the real problem?

- Waste-Related Issues: This is anything that eats up time, money, or effort without adding value. For a CACFP sponsor, it could be the 20 extra minutes staff spend double-checking meal kits because of confusing pack lists. In a warehouse, it might be the "extra touches" on a pallet that add no value but take up valuable time.

- Quality-Related Issues: These are all about mistakes, defects, and inconsistency. A WIC vendor might be dealing with the wrong items going into home delivery boxes, risking non-compliance. A 3PL could be seeing a high rate of picking errors that frustrate clients and drive up costs.

Knowing which of these is your primary battle is half the victory. Some frameworks, like Lean, are built specifically to hunt down and eliminate waste. Others, like Six Sigma, are designed to stamp out defects and variation.

Aligning Methods With Operational Goals

Once you've diagnosed the problem, you can start looking for the right cure. You don't need to become a certified black belt overnight, but understanding the core idea behind each method is essential.

I've seen it happen too many times: an organization gets excited about a popular framework but fails to consider if it actually fits their culture or the problem at hand. For instance, Kaizen thrives on small, continuous improvements from everyone on the team. That requires a very different mindset than a data-heavy Six Sigma project run by a few specialists.

A disaster response team that needs to get ready-to-eat meals out the door faster would get huge benefits from Lean principles, which are all about speed and eliminating bottlenecks. On the other hand, a healthcare plan running a Food is Medicine grocery program has to obsess over accuracy and compliance. For them, the defect-crushing power of Six Sigma is a much better fit.

For a deeper dive into how leading organizations are tackling these issues, I highly recommend exploring our thought leadership articles. Getting this alignment right from the beginning is what sets successful process improvement efforts apart from the ones that never quite get off the ground.

Process Improvement Methodologies At a Glance

To make this a bit easier, I've put together a quick comparison of the most common methodologies. Think of this as a cheat sheet to help you narrow down the best starting point for your organization's unique challenges.

| Methodology | Core Principle | Best For… | Example Application |

|---|---|---|---|

| Lean | Eliminate waste (muda) and maximize value. | Speeding up processes, reducing non-value-added steps, and improving flow. | A food bank redesigning its volunteer packing line to reduce wait times and movement. |

| Six Sigma | Reduce defects and variation through statistical analysis (DMAIC/DMADV). | Achieving near-perfect quality, ensuring compliance, and solving complex problems. | A WIC vendor using data to find the root cause of errors in home delivery orders. |

| PDCA Cycle | Plan-Do-Check-Act. A simple, iterative four-step cycle for continuous improvement. | Quick, incremental changes and testing new ideas on a small scale. | A CACFP sponsor piloting a new, clearer meal pack list with one team before a full rollout. |

| Kaizen | Continuous, incremental improvement involving every employee. | Building a culture of improvement, empowering teams, and making small, ongoing gains. | A 3PL holding weekly team huddles to identify and solve small warehouse inefficiencies. |

| Root Cause Analysis (RCA) | Digging deep to find the underlying cause of a problem, not just the symptoms. | Solving recurring or persistent issues that have no obvious solution. | An SFSP site investigating why meal counts are consistently off by using the "5 Whys" technique. |

This table isn't exhaustive, but it provides a solid foundation. The key is to see these not as rigid, competing systems, but as a toolkit. Sometimes, the best solution is actually a hybrid approach that borrows ideas from multiple frameworks to fit your specific operational reality.

Building Your Foundation With Value Stream Mapping

You can't fix a process you don't truly understand. It's a simple truth, but it's where so many improvement efforts go wrong. Teams often jump straight into solutions, armed with assumptions, without ever getting a clear, shared picture of how work actually gets done.

This is exactly where Value Stream Mapping (VSM) comes in, and why it's such a critical foundational tool. Think of it less as a flowchart and more as the visual story of your entire workflow, from the first trigger to the final delivery. VSM forces you to document every touchpoint, every handoff, and every frustrating delay.

The whole point isn't to draw a perfect diagram on day one. It’s about getting the right people in a room to agree on the current reality—warts and all. That shared understanding becomes the non-negotiable starting point for any change that's going to stick.

Assembling Your VSM Team

Your map is only as good as the people building it. One of the classic mistakes is a manager trying to map out a process alone in their office. For VSM to work, you need a cross-functional team of the people who actually do the work every single day.

So, who needs a seat at the table?

- Frontline Staff: The warehouse picker, the CACFP program coordinator, the delivery driver. Their on-the-ground insights are pure gold for spotting the real-world bottlenecks nobody else sees.

- Department Leads: You'll want supervisors from procurement, logistics, and program management who can speak to how work flows (or gets stuck) between departments.

- Upstream/Downstream Partners: Sometimes this means inviting a key supplier or even someone from a partner distribution site. They help you see the bigger picture beyond your own four walls.

Bringing this group together does more than just get information on a whiteboard. It shatters silos and sparks those "aha!" moments when one team finally understands how their actions create headaches for another.

The real power of a value stream map is getting everyone to agree on the current state. Once the team sees the delays and waste laid out visually, the motivation to find solutions builds naturally.

Mapping a Real-World Example

Let's make this tangible. Imagine a third-party logistics (3PL) provider that handles kitting and fulfillment for a nutrition security program. They're assembling multi-day kits with some tricky allergen-segregated components. The clock starts when they receive a weekly order file and stops when kits are delivered to 50 different program sites.

Your VSM team would gather around a whiteboard (or a virtual one) and walk through the process, step by painful step, capturing key data as they go.

Key Mapping Stages to Capture:

- Order Processing: How does that EDI order file arrive? How long does it take to get processed and turned into a work order the warehouse team can actually use?

- Component Picking: What's the real process for picking dry goods versus refrigerated items and those crucial allergen-free products? You'll want to note travel time and any delays here.

- Kitting & Assembly: Where does the packing happen? Time how long it takes to assemble one box, and be sure to document any quality control checks along the way.

- Labeling & Staging: How are boxes labeled for their specific destinations? Crucially, how long do they sit in the staging area before getting loaded? This is a notorious hidden bottleneck.

As you map this out, you’ll start to see the classic "eight deadly wastes" of Lean in action—things like waiting for components, unnecessary motion from pickers walking miles every day, or building too many kits before they're needed. These pain points are your roadmap for improvement. A smooth, waste-free process is also fundamental to any successful brand partnership, forming the bedrock of an effective private label packaging setup.

Driving Daily Wins With Lean And Kaizen

While value stream mapping gives you a fantastic big-picture view, Lean and Kaizen are where the rubber meets the road. These are the tools that let you take immediate, practical action on the ground.

This isn't about launching some massive, top-down corporate project. Instead, it’s about a relentless, daily hunt for small improvements—driven by the people who actually do the work. Your team.

This whole philosophy of continuous improvement has some deep roots, tracing back to the Toyota Production System (TPS) developed in post-war Japan. Toyota figured out that by focusing on eliminating waste and empowering every single employee to make small, steady improvements—the very essence of Kaizen—they could blow past their global competitors.

They achieved efficiency advantages of 40% or more. This approach, which the world came to know as Lean Manufacturing, completely changed the game, showing everyone how to make high-quality products at a fraction of the cost. You can learn more about the evolution of these powerful business improvement methodologies and see how they still influence complex logistics today.

Eliminating The Eight Wastes

The heart and soul of Lean is identifying and getting rid of "muda," the Japanese term for waste. It's really about looking at every step in your process with fresh eyes and asking one simple question: "Does this actually add value for the person we're serving?" Anything that doesn't is a prime target for improvement.

Once you know what to look for, you'll start seeing these wastes everywhere in food service and logistics:

- Transportation: A volunteer walking all the way across the warehouse just to grab packing tape for senior food boxes.

- Inventory: Assembling way too many multi-day SFSP kits that are now just sitting in cold storage, tying up valuable space and capital.

- Motion: A kitchen worker who is constantly bending, twisting, and reaching for ingredients because the workstation layout is a mess.

- Waiting: Delivery drivers sitting in their trucks, engines idling, while they wait for someone to finish the paperwork so they can start their routes.

- Overproduction: Prepping more CACFP meals than are needed for that day's count, which inevitably leads to food waste.

- Over-processing: Requiring three different people to sign off on a simple inventory adjustment that one person could easily handle.

- Defects: Packing the wrong item in a WIC home delivery order, forcing a second, costly trip to make it right.

- Skills: Failing to ask the veteran warehouse lead for input on a new pack list design, completely ignoring their years of hands-on knowledge.

The goal isn't just to work faster; it's to remove the obstacles that make work harder and slower than it needs to be. A simple change, like moving packing supplies closer to the assembly line, can save hundreds of hours over a year.

Putting Kaizen Into Action With Focused Events

So, if Lean provides the philosophy, Kaizen gives you the method. It’s about creating a culture where every team member feels comfortable and empowered enough to raise their hand and say, "I have an idea to make this better."

Sometimes this happens organically in daily huddles. But when you need to tackle a specific, nagging problem, a Kaizen event (also called a "blitz") is an incredibly powerful tool.

This is a short, intense workshop—usually lasting anywhere from one to five days—that pulls a cross-functional team together to solve one single problem. And it's not some theoretical exercise. The team is expected to implement and test a solution before the event is even over.

Let's imagine an SFSP program with a parent pick-up system that's pure chaos. Cars are backed up down the street, parents are getting frustrated, and your staff is completely stressed out. A Kaizen event is perfect for this.

Here’s how it would work:

- Go See the Process: The team spends the first morning just observing the current pick-up line. They're timing how long each car takes, mapping out the staff's movements, and talking directly to parents and staff to understand the real pain points.

- Brainstorm and Design: Now armed with actual data and feedback, the team gets together to brainstorm solutions. Maybe they create a separate lane for pre-orders. Maybe they redesign the check-in form to be simpler, or pre-pack the meal bags so they're just grab-and-go.

- Implement and Test: That same afternoon, they try it. They rearrange the traffic cones, test out the new forms with real parents, and see how the flow improves right there in real-time.

- Refine and Standardize: Based on what they saw during the test, they make a few small tweaks. Once they land on a process that is measurably better, they document it. We're not talking about a 50-page manual; this is a simple, one-page Standard Operating Procedure (SOP), probably with photos, to make sure everyone follows the new, better way from now on.

This approach delivers tangible results, fast. You move from problem to solution in days, not months, and it energizes your team by showing them that their ideas can create real, immediate change. This is how you embed continuous improvement into your organization's DNA.

Ensuring Quality And Compliance With Six Sigma

While Lean and Kaizen are fantastic for boosting speed and cutting out waste, some situations demand a level of quality that's close to perfect. Think about highly regulated environments like food programs or healthcare. Here, an error isn't just an inefficiency—it can jeopardize safety, trigger compliance violations, and shatter trust.

This is exactly where Six Sigma shines. It’s one of the most powerful process improvement techniques when quality is non-negotiable.

Six Sigma isn't about making small, gradual changes. It's a hardcore, data-driven methodology for systematically digging up and eliminating the root causes of mistakes and inconsistencies in any process. The ultimate goal? To make a process so stable and predictable that it produces fewer than 3.4 defects per million opportunities.

This framework got its start back in the 1980s, developed by Motorola engineer Bill Smith as a way to take on the superior quality of Japanese manufacturing. By the 90s, it was being adopted by industry giants, helping them save fortunes by slashing error rates. These early wins proved that statistical process control wasn't just for factory floors; it was a universal key to achieving incredible quality. You can learn more about the history and evolution of this methodology and see its impact on businesses worldwide.

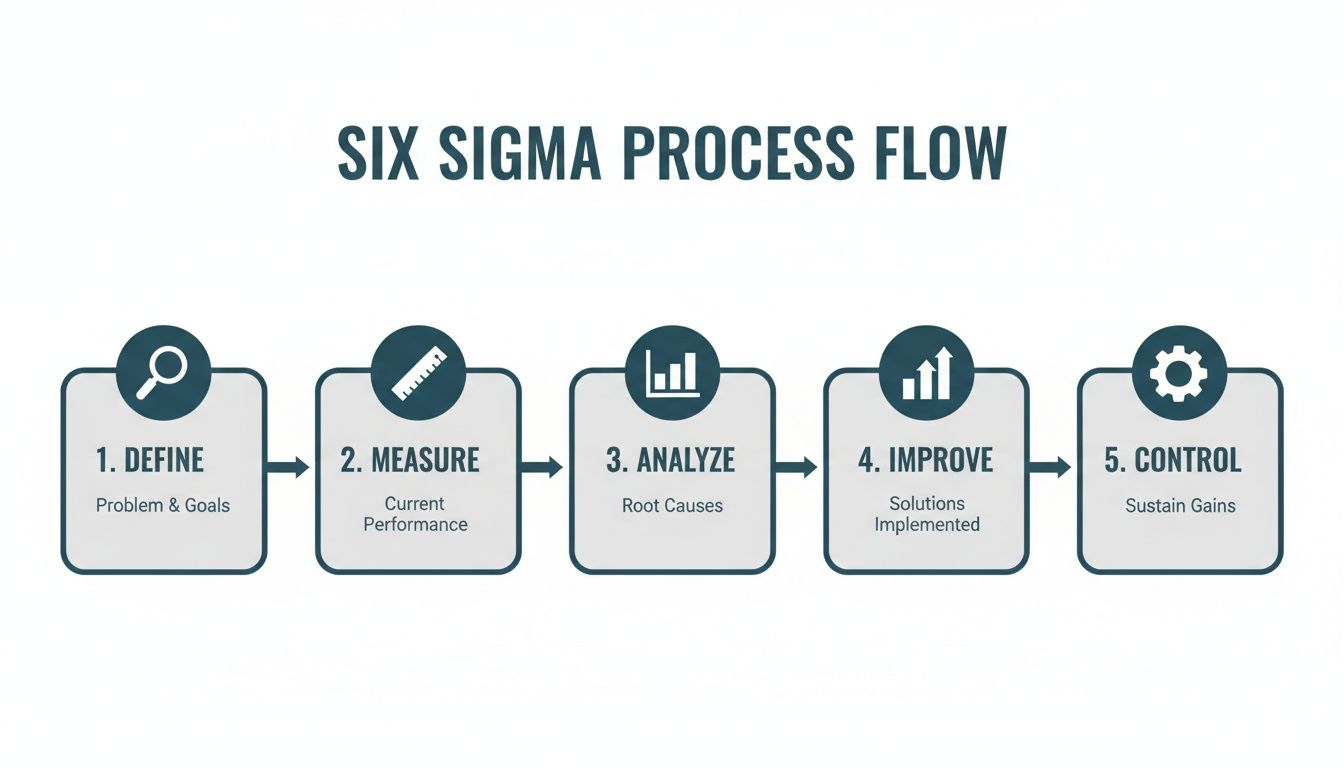

The DMAIC Framework

At the heart of any Six Sigma project is a five-phase roadmap called DMAIC. It stands for Define, Measure, Analyze, Improve, and Control. This structured approach gives you a clear path for untangling even the most complex quality problems.

1. Define: First things first, you have to clearly define the problem you're trying to solve, what the project goals are, and what your customers (or program participants) actually need. You have to get specific. A Managed Medicaid director overseeing a diabetes grocery program isn't just worried about "program outcomes." The real problem to define is: "How can we validate that our food kits are directly causing a measurable drop in participant A1c levels?"

2. Measure: Next, it's time to gather the data. You need to establish a baseline of how your process is performing right now. This phase is all about cold, hard facts—no assumptions allowed. For a WIC vendor manager, this might mean tracking the error rate in online orders, like how often an "inventory-aware substitution" sends out a non-compliant item.

3. Analyze: With solid data in your hands, you can start the detective work. The team digs into the numbers to find the root causes of the defects. Statistical tools often come into play here to pinpoint exactly where and why things are going sideways. The idea is to get past the symptoms and uncover the real source of the trouble.

4. Improve: Once you've identified the root cause, you can start developing, testing, and rolling out solutions to fix it. This could mean anything from redesigning a workflow and adding new quality checks to bringing in automation to eliminate the potential for human error.

5. Control: Finally, you lock in the gains. You establish controls to make sure the improvements stick for the long haul. This usually involves updating SOPs, training staff on the new way of doing things, and setting up a system to monitor performance over time. This last step is crucial for preventing the process from slowly sliding back into its old, error-filled habits.

Applying Six Sigma In The Real World

Let's imagine a WIC vendor manager is getting hammered with complaints about their new online ordering and home delivery system. Parents are frustrated because the "inventory-aware substitutions" are frequently wrong, leading to headaches and potential non-compliance with WIC-approved food lists. This is a perfect scenario for a Six Sigma approach.

-

Define: The project goal is crystal clear: reduce the substitution error rate to below 1% within three months.

-

Measure: The team meticulously tracks every single substitution error over a two-week period. They categorize them by item type, the warehouse picker who fulfilled the order, and the time of day. They discover a baseline error rate of 8%.

-

Analyze: As they dig into the data, a pattern emerges. They find that 75% of the errors happen with dairy and produce items, and they're most frequent during the evening shift when temporary staff are on duty. The root cause isn't just one thing; it's a combination of poor product images in the system and a lack of training for the temp workers.

The power of Six Sigma is that it forces you to look beyond the obvious. The problem wasn't just "bad substitutions"; it was a specific combination of system limitations and training gaps affecting a particular product category and shift.

Armed with these precise insights, the Improve phase becomes incredibly targeted. The team implements higher-quality product photos in the warehouse management system, creates a simple visual guide for common substitutions, and holds a mandatory 15-minute training huddle for all evening shift staff.

To wrap it up, in the Control phase, they establish a weekly audit of substitution accuracy. This ensures the new, lower error rate is sustained and doesn't creep back up. This is the methodical, data-backed power of Six Sigma in action.

How To Pilot, Measure, And Scale Improvements

A brilliant idea for a new workflow is just that—an idea. It’s a theory until you prove it works in the real world. Instead of overhauling your entire operation based on a hunch, the smartest move is to start small with a controlled pilot program.

This approach lets you test new process improvement techniques in a low-risk environment, gather actual data, and iron out the kinks before going all-in. Think of it as a dress rehearsal for your big show.

For a rural SFSP program testing a new home delivery model, a pilot might involve just one or two routes. This focused test allows the team to validate everything from pack lists to driver instructions without disrupting the entire service. It’s how a good idea becomes a proven, reliable process.

Designing A Meaningful Pilot

A successful pilot isn’t just about "trying something new." To be useful, it needs a clear structure and well-defined goals. Your pilot design should essentially be a miniature version of the scaled-up process, built to collect meaningful performance data.

So, where do you start? Begin by defining what success actually looks like. What specific metrics will tell you if the new process is a genuine improvement?

- Quantitative Metrics: These are your hard numbers. For a food bank, a goal could be to "reduce kitting time per senior box by 15%" or "decrease packing errors to less than 1%."

- Qualitative Metrics: Don’t forget the human element. Get feedback from the staff and volunteers who are hands-on with the pilot. Is the new process less stressful? Is it easier to learn? Their insights are pure gold.

Once you have your metrics, you need the right documentation. Clear Standard Operating Procedures (SOPs), updated pack lists, and simple audit checklists are non-negotiable. These tools make sure everyone involved in the pilot follows the new process consistently, which is absolutely critical for collecting clean, reliable data. To get a deeper handle on the efficiency of your new processes, it helps to understand effective methods for process evaluation.

From Measurement To Mastery

After running your pilot for a set period—maybe two weeks—it’s time to dig into the results. Did you hit your target metrics? The data will tell you what worked, what didn't, and what needs adjusting. This measurement phase is where you turn observations into actionable insights, much like the DMAIC cycle used in Six Sigma.

This visual shows the structured, five-step DMAIC approach—Define, Measure, Analyze, Improve, Control—which is the bedrock of data-driven process improvement.

Each step builds on the last, ensuring that any changes you make are based on solid evidence and built to last.

This structured approach is your safety net. It prevents you from scaling up a flawed process. If your pilot data shows the new workflow is only a slight improvement or, worse, introduces new problems, that's your cue to go back to the drawing board before committing more resources. This is a win, not a failure—you've just sidestepped a costly, large-scale mistake.

Scaling Success Across The Operation

Once your pilot has proven its worth and you’ve fine-tuned the process, you're ready to scale. This is where a great pilot can still stumble if the rollout isn’t managed well. Good change management is everything here.

Kick things off with comprehensive training. Use the rock-solid documentation you perfected during the pilot (your SOPs and checklists) as your training materials. Run hands-on sessions and make sure everyone understands not just what they need to do, but why this new process is better for everyone.

Think about it: in 1913, Henry Ford’s moving assembly line slashed Model T production time from over 12 hours to just 93 minutes. How? By emphasizing standardization and optimized movements. The same logic applies when you're scaling up compliant SFSP/CACFP multi-day kits for hundreds of childcare sites—a standardized pack list can cut errors dramatically.

Finally, set up a system for continuous monitoring. Your work isn’t done just because the new process is rolled out. Keep a close eye on those key metrics to ensure the gains you saw in the pilot are holding steady for the long term. This helps build a culture where improvement isn't just a one-off project, but an ongoing commitment to being the best you can be.

For organizations managing complex supply chains, exploring end-to-end logistics solutions can provide the backbone needed to support and sustain these scaled improvements.

Common Process Improvement Questions

Even the best-laid plans run into questions once you start applying them in the real world. This is where theory meets the messy, day-to-day reality of your operations. Here are a few of the most common questions we hear from food program and logistics managers, along with some straightforward advice to help you cut through the noise.

Our goal is to give you actionable insights you can apply with confidence, whether you're running a small food pantry or a large-scale 3PL.

How Do I Choose Between Lean and Six Sigma For My Food Bank Kitting Process?

This is a great question because it gets right to the heart of matching the right tool to the right problem. Your best bet really hinges on the primary challenge you're wrestling with on your kitting line.

Here’s a simple way to think about it:

-

Choose Lean for speed and flow. If your biggest headache is efficiency—volunteers standing around, bottlenecks slowing down the line, or too much time spent just walking to get supplies—Lean is your answer. It’s laser-focused on cutting out wasted steps and time to make the whole process faster.

-

Choose Six Sigma for quality and consistency. If your main problem is errors—the wrong items ending up in senior boxes, expired products slipping through, or box weights being all over the place—then Six Sigma is the better tool. It’s all about using data to find the root cause of defects and creating a process that's virtually error-proof.

Of course, many organizations eventually find a sweet spot by blending the two into "Lean Six Sigma." You can use Lean to speed things up, then bring in Six Sigma tools to make sure your faster process is also a higher-quality one.

What Is The Single Most Important First Step For A Small CACFP Sponsor?

When you're a small CACFP sponsor, time and resources are always tight. In that environment, the most powerful first step you can take is to conduct a Gemba walk. It’s a core technique from Kaizen, and the best part is, you don’t need any fancy software or expensive consultants to do it.

"Gemba" is a Japanese term that means "the real place"—where the work actually happens. The idea is simple: get out of your office and go see the process for yourself. Go to the kitchen, the packing area, or the delivery loading dock.

Just watch. Talk to the people doing the work. Ask what frustrates them, what takes too long, and what ideas they have for making things better. This direct observation will almost always reveal immediate, often simple, opportunities for improvement that can deliver a big impact without a big budget.

A Gemba walk is so powerful because it's grounded in reality, not assumptions. Your best ideas for improvement will almost always come from the frontline staff who live with the process every single day.

How Can Process Improvement Help With Government Program Compliance?

Process improvement isn't just about efficiency; it's absolutely fundamental to maintaining and simplifying compliance. Methodologies like Six Sigma are designed to create stable, predictable processes that minimize the risk of human error—which is often the root of compliance slip-ups.

Take an SFSP Rural Non-Congregate program, for instance. You could use these techniques to standardize your home-delivery kits, ensuring every single package meets strict Buy American and nutritional guidelines without fail. For a WIC vendor, mapping the online ordering workflow can help you build in safeguards that prevent unapproved item substitutions, eliminating a common source of errors.

By creating clear Standard Operating Procedures (SOPs) and audit checklists, you build a system that doesn’t rely on individuals remembering complex rules under pressure. This drastically reduces your risk of non-compliance and makes audit prep far less stressful. For more insights on this, exploring some common business automation questions can provide valuable context.

What Process Improvement Questions Should We Ask A Potential 3PL Partner?

When you’re vetting a third-party logistics (3PL) partner, you aren't just buying warehouse space; you're entrusting them with a critical piece of your operation and your reputation. Asking sharp questions about their documented processes is key.

Go beyond the basics of price and capacity. You need to dig into their commitment to quality and continuous improvement. Try asking pointed questions like these:

- "Can you show us your documented SOPs for allergen-segregated storage and kitting?"

- "What is your process for managing inventory accuracy, and what are your current metrics?"

- "How does your Warehouse Management System (WMS) handle exceptions or last-minute order changes?"

- "Can you walk us through your quality control checkpoints for a multi-pack assembly project?"

A truly solid 3PL partner will welcome these questions. They'll be able to show you that they have robust, repeatable processes in place—and that’s the best assurance you can get that they can protect your brand and deliver on their promises.

At Umoja Health, we don't just supply food; we provide the operational expertise to help our partners run compliant, efficient, and impactful programs at scale. If you're looking to strengthen your food program's logistics and compliance, we can help. Learn more about our solutions at https://umojahealth.com.