Finding the right warehouse isn't about browsing listings—it's about a deep, honest look at your own business first. The entire search hinges on turning your daily operations, your specific inventory needs, and your growth ambitions into a rock-solid facility blueprint. Get this part right before you start looking, and you'll sidestep costly mistakes and land a space that actually fuels your long-term success.

Defining Your Operational Needs Before You Search

Jumping into warehouse listings without a clear plan is like going grocery shopping when you're starving. You’re guaranteed to make impulsive, expensive choices that you'll end up regretting. The most important work you'll do when renting a warehouse happens right at your own desk, long before you ever step foot on a property. It's all about a thorough needs assessment that turns your business goals into a tangible checklist.

This is about so much more than just guessing your square footage. You need to map out every single touchpoint of your product's journey, from the second it arrives at your door until it’s on a truck headed to a customer. A detailed plan not only makes your search laser-focused but also gives you serious leverage when it's time to negotiate the lease. It ensures you don't pay for features you’ll never use or, even worse, overlook something absolutely critical.

From Daily Volume to Workflow Zones

First, let's get concrete with your numbers. How many pallets do you really receive each day? What’s the average number of orders you pick, pack, and ship out? These figures directly determine the number and size of receiving docks you need and dictate how you should lay out your packing stations. A business shipping 500 small parcels a day has completely different facility needs than one moving 20 large freight pallets.

With those metrics in hand, start visualizing your workflow. A smart layout is your best defense against bottlenecks and wasted labor. You need clearly defined zones for a smooth, productive operation.

- Receiving Area: This needs to be more than just a patch of floor. You need real space for inbound pallets, quality control checks, and breaking down shipments. And it has to be right next to the loading docks—that's non-negotiable.

- Storage and Inventory: This is where clear height is king. A warehouse with a 24-foot clear height can effectively double your storage capacity compared to a 12-foot ceiling, all without taking up another square foot of floor space.

- Picking and Packing Stations: Put these in a central location to slash travel time for your team. Don't forget to account for space for packing materials, scales, and label printers.

- Shipping and Staging: You need a dedicated spot where outbound orders can be consolidated and staged before the carrier arrives. This simple step prevents absolute chaos and costly shipping errors.

The goal is to create a one-way flow for your inventory. A product should move in a straight or U-shaped line—from receiving to storage, to picking, to packing, and finally out the door. No backtracking. This one principle can be a game-changer for your operational speed.

Specialized Requirements and Future-Proofing

Does your inventory have unique needs? The details here are what separate a good warehouse from a great one. If you're storing food, you absolutely need an FDA-registered facility with ironclad pest control and sanitation protocols. For businesses handling products with allergens like nuts or gluten, documented allergen-segregated storage areas are a must to prevent cross-contamination. And if you're in the world of perishable goods, a warehouse with cold chain management capabilities—think refrigerated or frozen zones with constant temperature monitoring—is essential.

Looking ahead is just as critical. The global warehousing market is projected to hit $869.32 billion by 2025, largely driven by the relentless growth of e-commerce. With automation poised to cut labor costs by up to 30%, planning for future tech integration is just plain smart.

Finally, think about growth. The warehouse you sign a lease on today needs to work for you for the next three to five years. A good rule of thumb is to secure 15-25% more space than you currently need. This buffer gives you breathing room for seasonal inventory spikes, new product launches, and general business growth, saving you from a premature and incredibly disruptive move.

For companies that need a comprehensive solution without the long-term lease commitment, exploring options like food-grade 3PL services for kitting and storage can provide a scalable, flexible alternative. This kind of strategic foresight ensures your warehouse becomes a catalyst for growth, not a constraint.

Choosing the Right Location and Lease Structure

Finding the right warehouse isn't just about getting four walls and a roof over your inventory. It’s a massive strategic decision. The right spot can dramatically cut your transportation costs, speed up delivery times, and even make it easier to find and keep great employees. Think of your warehouse as the heart of your supply chain—if it’s in the right place, everything else just flows better.

Once you’ve got a location in mind, you’ll be staring down a lease agreement. This isn't just a piece of paper; it’s the financial and operational rulebook you'll live by for years. Understanding the fine print, from lease types to key negotiation points, can save you a fortune and a world of headaches later on.

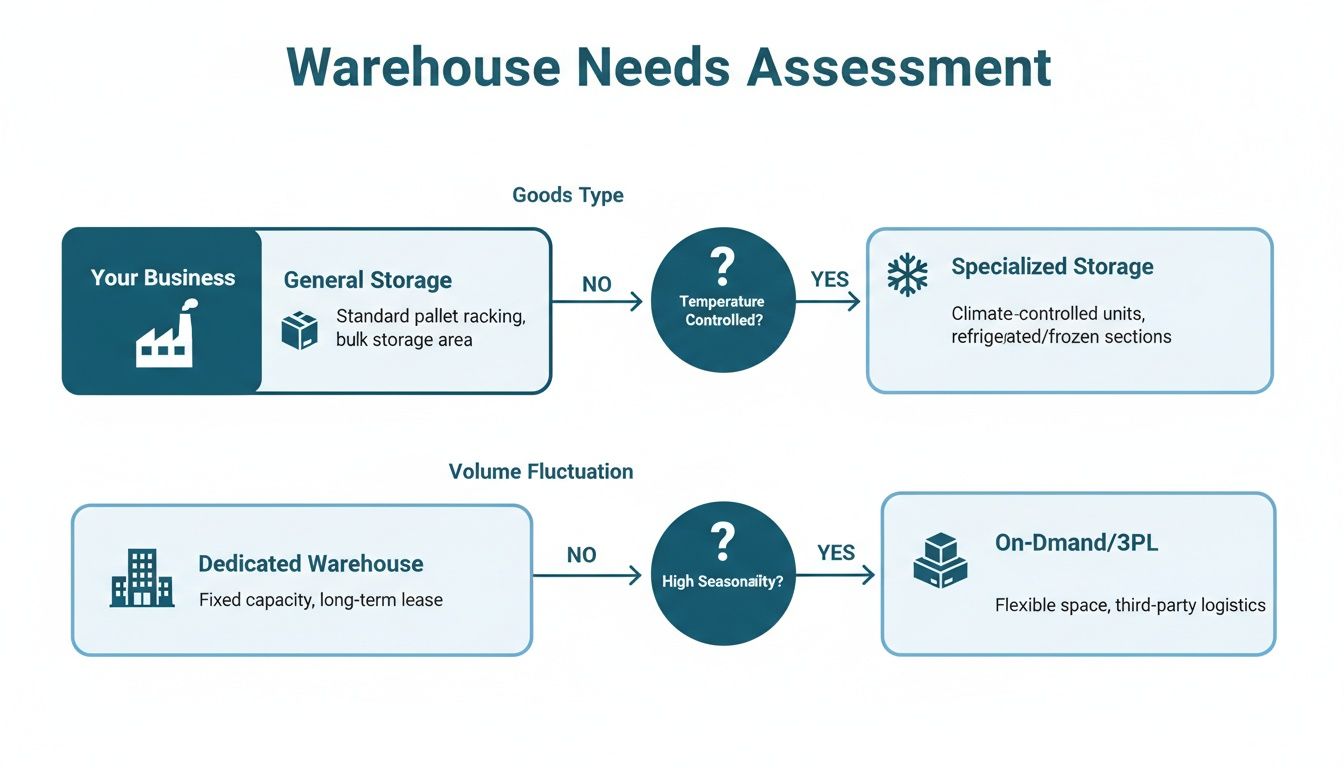

This decision tree helps visualize the initial assessment, guiding you from your core business type toward either a general or specialized warehouse path.

The takeaway here is simple: Nail down your core operational needs early, and every other decision, from the site visit to signing the lease, becomes much clearer.

Analyzing Site Selection and Logistics

Your warehouse's address dictates how fast—and how cheaply—you can move your products. A building five minutes from a major highway is worlds apart from one buried on congested city streets. Proximity to interstates, ports, and rail lines directly impacts your freight costs, both for goods coming in and orders going out. For an e-commerce brand that built its reputation on two-day shipping, this is everything.

Look beyond the highways and consider your team. Can people actually get to this location? A warehouse with no public transit access or one that requires a brutal commute is going to be a tough sell for potential hires.

Finally, and this is a big one, you have to dig into local zoning laws. These rules determine what kind of business you can legally run in a specific area. You absolutely cannot sign a lease for a food distribution hub in a zone that’s only approved for light industrial manufacturing. Checking the zoning isn't just a suggestion; it's a critical step to avoid a legal and financial nightmare.

Decoding Commercial Lease Types

Not all warehouse leases are built the same. The structure of the agreement spells out who pays for which expenses, and that has a huge effect on your real monthly cost. Before you even think about negotiating, you need to understand the three main flavors of commercial leases.

When you're looking to rent a warehouse, you'll likely encounter one of these three lease structures. Each one divides the responsibility for property expenses differently between you (the tenant) and the landlord. Getting this right is crucial for accurate budgeting.

Comparing Commercial Warehouse Lease Types

| Lease Type | Tenant Responsibility | Landlord Responsibility | Best For |

|---|---|---|---|

| Triple Net (NNN) | Base Rent + Property Taxes, Insurance & Common Area Maintenance (CAM) | Major structural repairs (roof, foundation) | Businesses wanting lower base rent and more control over operational costs. The most common for warehouses. |

| Modified Gross (MG) | Base Rent + some operating expenses (e.g., utilities, janitorial) | Taxes, Insurance, CAM, and major structural repairs | Companies seeking a balance between the predictability of a Gross lease and the lower base rent of an NNN lease. |

| Full-Service Gross | One flat monthly rental payment | All operating expenses, including taxes, insurance, CAM, and often utilities | Startups or businesses that need highly predictable monthly costs and minimal property management duties. |

Most businesses renting a warehouse will find themselves looking at a Triple Net (NNN) lease. The base rent can look incredibly appealing, but you have to factor in the "nets"—taxes, insurance, and CAM. These can easily add another 25-50% to your monthly payment, so be sure to budget accordingly.

Negotiating Favorable Lease Terms

The good news? The current market often favors tenants. As of mid-2025, U.S. vacancy rates for warehouses over 100,000 SF have climbed to 7.6%, and the supply-to-demand ratio is a healthy 4:1. This gives you real leverage at the negotiating table.

When you sit down to talk terms, think beyond the monthly rent. There are a few key clauses that can make or break your lease financially.

- Tenant Improvement (TI) Allowance: This is cash from the landlord to help you customize the space. It can cover anything from building out offices to installing specialized lighting or upgrading the electrical system.

- Renewal Options: Lock in the right to renew your lease at a pre-agreed rate. This is your shield against being priced out or kicked out when your term is up.

- Early Termination Clause: Life happens. This clause gives you an exit plan if your business grows faster than expected or needs to pivot, though it will likely come with a penalty fee.

Always—and I mean always—have a commercial real estate attorney review your lease before you sign. Their fee is a small price to pay for the expertise they bring in spotting risky clauses and protecting your interests. For companies that need specialized capabilities like FDA-registered food-grade storage but want to avoid a long-term lease commitment, a full-service 3PL partner like Unidad Logistics is an excellent alternative.

Mastering Compliance and Specialized Requirements

When you're renting a warehouse, especially for sensitive industries, the four walls and a roof are just the beginning. The real challenge often lies in navigating the complex web of regulations that govern your operations. Getting compliance wrong isn't just a paperwork headache; it can mean crippling fines, huge inventory losses, and a black eye for your brand's reputation.

For anyone handling food, pharmaceuticals, or other regulated goods, compliance is the absolute foundation of the business. It touches everything, from daily sanitation schedules to the way you train your team. This isn't about just checking a box to meet the minimum standard. It's about creating a culture of safety and quality that protects your products, your people, and your customers. Before you even think about signing a lease, you have to do your homework and confirm the property meets all relevant rules, including understanding local zoning laws.

Navigating Food-Grade Warehouse Standards

If your products are going to be consumed, the compliance bar is set incredibly high. An FDA-registered warehouse is the bare minimum, and honestly, registration is just the first step. Keeping that status means you're locked into a strict set of protocols designed to stamp out any chance of contamination and keep your products safe.

It all starts with a documented, rigorously enforced sanitation schedule. Then there's your pest control program, which needs to be comprehensive, with regular inspections and detailed logs. Every square inch of the facility, from the dock doors to the highest rack, has to be covered.

A huge piece of the food-grade puzzle is your allergen control plan. Cross-contamination can have life-or-death consequences, so you need a bulletproof system for keeping products with common allergens—think peanuts, dairy, gluten—completely separate. This usually involves:

- Designated Storage Zones: Physically separate areas for different allergen groups.

- Color-Coded Equipment: Using specific pallet jacks, tools, and bins for allergen-free zones.

- Clear Labeling and Signage: Making sure every employee can instantly identify segregated areas.

Cold Chain Management and Temperature Control

For businesses in the perishable goods game, maintaining the cold chain is everything. A temperature slip of just a few degrees can wipe out thousands of dollars of inventory in the blink of an eye. A truly compliant cold chain operation isn't just about having good refrigeration units; it's about constant monitoring and validation.

Your warehouse needs to have temperature monitoring systems that feed you real-time data and send alerts the second something is off. This lets you jump on a problem before it becomes a disaster. It's also critical to have clear Standard Operating Procedures (SOPs) for how temperature-sensitive products are handled during receiving and shipping to keep their time on the dock to an absolute minimum.

A strong compliance culture isn't built on rules alone; it's built on proactive monitoring and continuous improvement. Your goal should be to find issues before an auditor does.

Upholding OSHA Safety Standards

Beyond product-specific rules, every single warehouse has to live by Occupational Safety and Health Administration (OSHA) standards. These regulations are there to protect your most important asset: your people. A safe warehouse is an efficient one, and cutting corners on OSHA guidelines is a fast track to workplace accidents, injuries, and serious operational downtime.

The big areas of focus for OSHA compliance usually include:

- Forklift Operation: Every operator must be properly certified and stick to strict safety protocols. No exceptions.

- Racking Integrity: Racks need to be installed by pros, have clearly posted weight limits, and be inspected for damage on a regular basis.

- Emergency Preparedness: This means clearly marked exits, accessible fire extinguishers, and an evacuation plan that everyone knows by heart.

Building this compliance framework is a lot of work, but it's one of the most important investments you'll make. It ensures your business runs safely, legally, and effectively, giving you a solid foundation to build on.

Budgeting Beyond the Monthly Rent Check

When you're hunting for a warehouse, it's easy to get tunnel vision. All you see is that big, bold base rent number on the listing. But focusing only on that figure is a classic rookie mistake—it tells just a fraction of the real financial story.

The true cost of operating a warehouse is a mosaic of one-time setup fees, recurring operational expenses, and critical technology investments. If you’re not prepared, these costs can absolutely blow up your budget. A smart budget turns these potential surprises into predictable, manageable line items.

Accounting for One-Time Setup Costs

Before a single pallet of your inventory rolls through the door, you’ll be hit with a series of upfront costs just to get the space operational. These are capital-intensive, one-off investments that demand careful planning.

Here’s what you should expect to pay for right out of the gate:

- Security Deposit: Standard practice. Plan for the equivalent of one or two months' gross rent to secure the lease.

- Initial Build-Out: This covers any changes needed to make the space work for you, like building out office space, adding specialized lighting over packing stations, or installing floor drains for sanitation.

- Racking and Shelving Installation: That empty warehouse is just a big box. You'll need to buy and professionally install the pallet racking and shelving systems designed for your inventory's specific weight and volume.

- Utility and Service Activation: Don't forget the fees to get the lights on and the internet running. Activating electricity, water, gas, and high-speed internet can sometimes require deposits, too.

Unpacking Recurring Operational Expenses

Once you're up and running, your monthly financial commitment goes way beyond that rent check. These ongoing costs are simply the price of doing business in your new space.

This is especially true if you’ve signed a Triple Net (NNN) lease, which is the most common structure for industrial properties. Under an NNN lease, you're on the hook for your share of the building's major operating expenses, often bundled together as Common Area Maintenance (CAM) fees.

Your real monthly cost is the base rent plus the "nets." As a rule of thumb, budget an extra 25-50% of your base rent to cover these variable operational expenses. This buffer will save you from some serious financial headaches.

These recurring costs almost always include:

- Property Taxes: Your slice of the property's annual tax bill, paid monthly.

- Building Insurance: This covers the physical structure. You'll still need your own policies for liability and your contents.

- Common Area Maintenance (CAM): This bucket covers landscaping, parking lot upkeep, snow removal, and maintaining any shared facilities.

- Utilities: Your direct costs for electricity, water, gas, and trash disposal.

- Pest Control and Janitorial Services: These are non-negotiable for maintaining a clean and compliant facility, especially if you're in the food and beverage space.

Factoring in Technology and Systems

In today's logistics world, technology isn't a "nice-to-have"—it's the core of an efficient operation. The right systems drive accuracy, boost productivity, and give your business room to scale. Budgeting for these tools from day one is non-negotiable.

Here are the key technology investments to plan for:

- Warehouse Management System (WMS): This software is the brain of your operation. A WMS directs everything from receiving and putaway to picking, packing, and shipping, giving you real-time control.

- Electronic Data Interchange (EDI): EDI is how you automate communication with retail partners and suppliers. It gets rid of manual order entry and dramatically cuts down on costly errors.

- Security Systems: This includes everything from CCTV cameras and access control systems to alarm monitoring services that protect your inventory and assets.

While the market is always moving, recent trends have created some interesting opportunities for tenants. Warehouse leasing demand saw its first quarterly dip in 15 years back in Q2 2025, but the long-term outlook still points to a need for up to 1.1 billion more square feet by 2028, thanks to e-commerce. You can learn more about why warehouse demand is shifting on marketplace.org. This temporary shift could give you the leverage to negotiate better terms and build a more stable budget.

By understanding the total cost of occupancy, you move from simply renting a space to making a smart, sustainable investment in your business's future.

Designing Your Warehouse for Maximum Efficiency

You’ve signed the lease. Now the real work begins. An empty warehouse is a blank canvas, giving you a rare chance to engineer your operational flow from the ground up. This isn't just about filling space—it's about designing a system that gets the most out of every square foot, every labor hour, and every piece of tech you put in place.

A well-designed layout can turn a simple storage building into a high-performance fulfillment engine. The goal is a logical, streamlined path for inventory that cuts out backtracking, prevents bottlenecks, and makes every task—from receiving to shipping—as smooth as possible.

Crafting a Winning Warehouse Layout

The foundation of an efficient warehouse is its workflow. You want your inventory's journey to be a one-way street, moving seamlessly from one station to the next without ever doubling back. This linear or U-shaped flow is the cornerstone of a productive operation.

Start by mapping out your key zones:

- Receiving: This area needs plenty of room right by the dock doors for inbound inspection, quality control, and breaking down pallets.

- Put-Away and Storage: This will be your largest zone. The layout here has to make storing goods fast and accurate.

- Picking and Kitting: Position this area to minimize how far your team has to travel. This is where individual items are picked for orders and, if you do it, assembled into kits.

- Packing and Shipping: The final stop. This zone needs space for packing materials, scales, printers, and a staging area for outbound trucks.

Just optimizing this flow can dramatically reduce travel time, which often eats up more than 50% of a picker's day. Even small tweaks, like placing your fastest-moving products closest to the shipping area, can deliver huge productivity gains.

The most common mistake I see businesses make is underestimating how much space they need for clear, wide aisles. Skimping here creates traffic jams for forklifts and pallet jacks, slowing down the entire operation and creating serious safety hazards.

Selecting and Installing Racking Systems

Your racking is the skeleton of your warehouse. The right system maximizes your vertical space—your most valuable and underused asset—and keeps your inventory safe and accessible. Your choice will come down to your product type, weight, and how fast it moves. Getting this right is critical; you can learn more about choosing industrial storage racks to see what best fits your specific needs.

For instance, a business shipping thousands of different small SKUs might go for high-density shelving. On the other hand, a company moving uniform pallets of a single product would be better off with a standard selective pallet rack system. Whatever you choose, always have it professionally installed and clearly labeled with its maximum weight capacity to meet OSHA standards.

Integrating Technology for Accuracy and Speed

In modern logistics, trying to do everything by hand is a liability. Technology is what elevates a good layout into a great one, giving you the data and automation you need for precision and scale. Two systems are non-negotiable.

First, a Warehouse Management System (WMS) is the brain of your operation. It gives you real-time visibility into your entire inventory, directing every task from receiving and put-away to optimized picking paths and shipping verification. It’s your single source of truth for what you have and where it is.

Second, Electronic Data Interchange (EDI) automates communication between you and your partners, like major retailers or suppliers. It replaces manual purchase orders and invoices with standardized electronic documents, which drastically cuts down on errors and speeds up the entire order-to-cash cycle. Technology is also vital for specialized tasks; for example, many companies rely on specific software to manage complex workflows like those in food-grade kitting programs.

Finally, remember that a great warehouse still depends on its people. Develop clear Standard Operating Procedures (SOPs) for every single task, from receiving a shipment to packing an order. Comprehensive training on these SOPs, your WMS, and your safety protocols is what ensures consistency, reduces errors, and creates a safe, productive environment for your team.

Your Top Questions About Renting a Warehouse

Even with the best plan in hand, renting a warehouse for your business can feel like navigating a maze. A lot of questions pop up, and getting straight answers is the only way to move forward with confidence.

Let's dive into some of the most common questions we hear from business owners. We'll cover everything from the real-world costs you can expect to the lease clauses that can make or break your operation.

How Much Does It Really Cost to Rent a Small Warehouse?

This is usually the first thing people ask, but the answer isn't a single number. The "sticker price"—the base rent—can be all over the map depending on the location and quality of the building. For instance, a 5,000-square-foot space in a hot logistics area could easily run you over $10,000 a month. That same size in an older building off the beaten path might be closer to $4,000.

But here's the catch: the base rent is just the starting line. You absolutely have to budget for the extra operational costs, especially if you're looking at a Triple Net (NNN) lease.

As a solid rule of thumb, budget an extra 25-50% of your base rent to cover these NNN costs. If a warehouse has a $6,000 monthly base rent, you should plan on a total monthly spend of anywhere from $7,500 to $9,000.

What are these extra costs? They typically include your share of:

- Property Taxes: Your slice of the building's overall tax bill.

- Building Insurance: This covers the landlord's structure, not your stuff inside.

- Common Area Maintenance (CAM): These are the fees for things like landscaping, parking lot care, and snow removal.

Before you get serious about any space, always demand a detailed breakdown of these NNN costs from the landlord.

What Key Clauses Should I Look for in a Warehouse Lease?

That lease agreement is a dense, legally-binding document. It’s easy to get overwhelmed, but zeroing in on a few critical clauses can save you from massive headaches later. You need to look beyond the monthly rent and lease term and get into the nitty-gritty.

Here are four clauses that need your undivided attention:

- The 'Use' Clause: This section spells out exactly what you're allowed to do in the space. If it’s too restrictive—say, it only permits "general storage"—but you plan on doing food kitting or some light assembly, you could technically be violating your lease. Make sure it’s written broadly enough to cover everything you do now and might do in the future.

- Tenant Improvement (TI) Allowance: This is a huge negotiation point. It’s the amount of money the landlord agrees to kick in for your custom build-out. A good TI allowance can save you a ton of cash upfront.

- Maintenance and Repairs: This clause gets specific about who fixes what. Tenants are usually on the hook for interior, non-structural issues, while the landlord handles big-ticket items like the roof, foundation, and exterior walls. Knowing this distinction can save you from surprise repair bills.

- Renewal Options and Escalation Clauses: First, understand your rights to renew the lease. Just as important, know how much your rent is going to go up each year. The escalation clause defines that annual rent hike, so make sure it's a predictable and reasonable rate.

Seriously, the complexity here is no joke. We always recommend having a commercial real estate attorney give the lease a thorough review before you even think about signing.

When Is Using a 3PL Better Than Renting a Warehouse?

Having your own warehouse gives you total control, but it's not the right play for every business. Sometimes, partnering with a Third-Party Logistics (3PL) provider is a much smarter, more strategic move.

A 3PL is probably the better option if your business needs to:

- Stay Flexible: If you deal with big seasonal spikes or unpredictable sales, a 3PL lets you scale your space and labor up or down instantly. You only pay for what you use, so you’re not stuck with a half-empty warehouse during the slow season.

- Avoid Big Upfront Costs: Leasing means coming up with a security deposit, paying for a build-out, and buying all your own racking and equipment. A 3PL wipes those major capital expenses right off the table.

- Outsource Tricky Compliance: Need specialized handling like FDA-registered food storage, allergen segregation, or cold chain management? A good 3PL already has the certifications, infrastructure, and trained staff to do it right. You get to tap into their expertise without having to build it all from scratch.

- Focus on What You Do Best: Running a warehouse is a business in itself. Handing off the logistics and fulfillment to a 3PL frees you up to concentrate on what actually grows your company: product development, marketing, and sales.

At the end of the day, if you value agility and want to sidestep long-term commitments and financial risk, a 3PL is a powerful alternative to renting.

For businesses that need expert, compliant logistics without the headache of a lease, Umoja Health offers a complete range of FDA-registered 3PL services through Unidad Logistics. Find out how our food-grade storage, kitting, and fulfillment solutions can help you grow.