When you think about your program's expenses, what comes to mind first? For most, it's the food itself. But your true cost of service is so much more than that. It’s the grand total of every single direct and indirect expense required to get a meal from your warehouse into someone's hands.

Think of it like an iceberg. The food procurement costs you see on the invoice are just the tip. Lurking beneath the surface is a massive, hidden foundation of expenses—labor, storage, compliance, and a dozen other things. Getting a firm grip on this complete picture is absolutely essential for accurate budgeting, sustainable operations, and ultimately, scaling your impact.

Uncovering the Full Cost of Service

It’s a common mistake for organizations to equate the cost of goods with their total operational spend. This tunnel vision inevitably leads to underfunded programs and models that just can't last. The real cost of service is a complex calculation that has to account for every touchpoint in your supply chain, from the moment you source an item to the final delivery.

This guide is designed to give program managers at food banks, government agencies, and healthcare organizations a clear framework to master their operational finances. We'll walk through each component, piece by piece, offering practical ways to calculate and manage your complete spending.

Beyond the Price Tag

Calculating this all-in number demands a shift in mindset. You have to start accounting for every activity that supports service delivery, even those that don't seem directly tied to a single meal kit. While the context is different, it's helpful to see how other industries tackle this; for instance, guides decoding the cost of software development often provide a great roadmap for breaking down similar direct and indirect cost structures.

So, what are these hidden costs? Here are a few major categories that often fly under the radar:

- Labor Costs: This isn't just your warehouse crew. It’s the program managers, the compliance officers, and the administrative staff who keep the wheels turning.

- Facility Overhead: Rent, utilities, insurance, and maintenance for your storage and kitting facilities are significant, steady contributors to your bottom line.

- Technology and Systems: Those monthly fees for Warehouse Management Systems (WMS), Electronic Data Interchange (EDI), and specialized reporting software add up quickly.

- Compliance and Reporting: The time and resources poured into meeting specific program requirements—whether for USDA grants or Food is Medicine initiatives—are substantial and very real costs.

To help you start organizing these moving parts, here's a quick look at the core components we'll be diving into.

Key Cost of Service Components at a Glance

| Cost Category | Description | Example for a Food Program |

|---|---|---|

| Direct Product Costs | The purchase price of all food and non-food items in a kit. | Cost of canned vegetables, pasta, protein, and juice boxes. |

| Kitting & Labor | All labor expenses for assembling kits, including wages and benefits. | Paying staff to pack 1,000 meal boxes for a weekend SFSP. |

| Storage & Warehousing | Costs for facility rent, utilities, insurance, and equipment. | Monthly lease on a warehouse with cold storage for produce. |

| Fulfillment Fees | Transactional costs for picking, packing, and preparing orders. | A per-box fee charged by a 3PL for packing diabetes-friendly kits. |

| Last-Mile Delivery | All expenses related to transporting kits to their final destination. | Fuel, driver wages, and vehicle maintenance for home delivery routes. |

| Compliance Overhead | Administrative costs for meeting program rules, tracking, and reporting. | Staff time spent on generating USDA-required monthly reports. |

This table provides a high-level map of where we're headed. Each of these categories represents a critical piece of the financial puzzle.

The numbers don't lie. Within the US food service contractors industry, operating costs consume a massive portion of revenue. Purchases make up 75-80% of the spend, followed by wages at 10-15%. This leaves razor-thin profit margins of about 3-5%. That data alone underscores how critical it is to track every single expense to stay financially healthy. By adopting this more detailed, iceberg-view of your costs, your organization can build programs that are resilient, effective, and ready to scale.

Mapping Your Direct Costs From Procurement to Storage

To get a true handle on your total cost of service, you have to start with the most tangible expenses—the ones you can literally see, touch, and track on a spreadsheet. These are your direct costs, and they form the concrete foundation of your budget. Think of it like building a house: you have to pour the slab and frame the walls long before you start picking out paint colors.

These foundational expenses really boil down to three main pillars: product procurement, kitting and assembly, and warehousing. Each one comes with its own set of variables that can swing your final per-kit cost one way or the other. Getting these right is the first critical step toward building a food program that's both sustainable and financially predictable.

The True Cost of Product Procurement

Sourcing your products is so much more than just finding the cheapest can of beans. Smart procurement is a delicate dance, balancing cost, compliance, and the actual needs of the community you serve. For a program focused on seniors, that might mean locking in prices on specific OAA-compliant items before seasonal demand sends costs soaring.

For other programs, the priority might be sourcing culturally connected foods that truly resonate with local families. That requires deeper relationships within the supply chain and might look different on paper, but the value it delivers goes far beyond basic nutrition. These decisions are ground zero for your budget, as product costs are almost always the single biggest chunk of your direct spending.

Key Takeaway: Great procurement isn't just about the price tag. It's about strategic sourcing that aligns with everything from program rules (like Buy American provisions for SFSP) to participant dignity and long-term budget health.

Kitting and Assembly Labor Expenses

Once the products are in the door, your next direct cost is the labor it takes to assemble everything into ready-to-go kits. This is a huge opportunity for savings if you're smart about it. The cost here isn't just an hourly wage; it's a direct measure of time and motion. How many minutes does it take one person to build one box?

This is precisely why having clear, volunteer-friendly Standard Operating Procedures (SOPs) is a game-changer. A simple workflow that cuts down on steps and confusion can slash your labor cost per kit, whether you're using paid staff or wrangling volunteers. And don't forget the physical materials—the cardboard boxes, packing tape, and any dividers are all direct costs that need to be in your calculation.

As organizations grow, figuring out the details of a streamlined https://umojahealth.com/private-label-packaging-setup/ can unlock even more efficiency in this part of the process.

Navigating Warehousing and Storage Costs

Finally, before a single kit goes out for delivery, it's sitting in your facility racking up storage costs. Warehousing isn’t a flat fee; the price tag shifts depending on exactly what you need to store. A major piece of this is the inventory carrying cost, which covers not just the space but also things like insurance and the risk of spoilage.

The type of storage you need is the biggest cost driver. Here’s a quick look at what we typically see in food programs:

- Ambient Storage: This is your basic, room-temperature storage for shelf-stable goods like pasta, grains, and canned foods. It's the most straightforward and cost-effective option.

- Temperature-Controlled Storage: If you're dealing with produce, dairy, or frozen items, your costs jump. Refrigeration and freezing require specialized equipment and use a lot more energy.

- Allergen-Segregated Storage: In FDA-registered facilities, preventing cross-contamination is non-negotiable. Creating separate, controlled zones for allergens like nuts, soy, or gluten takes up more space and requires careful management, which adds to the bottom line.

Each of these direct cost pillars—procurement, kitting, and storage—needs to be tracked with precision. They are the most visible and controllable expenses you have. By breaking them down, you can start building a cost-of-service model that truly reflects reality.

Decoding Fulfillment and Last-Mile Delivery Expenses

Once your meal kits are sourced, packed, and stored, you hit what’s often the most complicated and unpredictable part of your cost of service: actually getting them into the hands of participants. This is where fulfillment and last-mile delivery come in, and it's where tiny operational details can blow up your budget.

Think of it this way: all your direct costs up to this point—procurement, kitting, storage—are like building a car. They are the essential, fairly predictable parts like the chassis, engine, and wheels. But fulfillment and delivery? That’s the fuel and the final road trip. The cost can swing wildly depending on the traffic, the terrain, and exactly where you're going.

This is where the behind-the-scenes magic of a fulfillment center happens. These costs aren't just about labor. They include the technology that makes large-scale distribution even possible, like Warehouse Management Systems (WMS) and Electronic Data Interchange (EDI) integrations that keep orders flowing and tracked automatically.

The Critical Last Mile

That final journey from a warehouse to a person’s doorstep—the last mile—is notoriously the most expensive piece of the entire logistics puzzle. This single leg of the trip can eat up more than half of your total shipping budget.

For programs that count on direct-to-home delivery, like SFSP Rural Non-Congregate models or innovative WIC mobile shopping pilots, getting a handle on last-mile costs isn't just important; it's non-negotiable.

To really get it, you have to see the difference between two main shipping models:

- Bulk Freight (LTL/FTL): This is for moving big batches of goods between hubs, like from a central warehouse to a regional food bank. Less-Than-Truckload (LTL) and Full Truckload (FTL) are your go-to options for moving product in bulk, and it's far more cost-effective.

- Parcel Shipping: This is about sending individual boxes straight to homes using carriers like UPS or FedEx. It's incredibly convenient for the families you serve, but the cost for each box is much, much higher than shipping in bulk.

The smartest strategy usually involves a blend of both. You might use FTL to ship pallets of kits to a local community partner, who then takes care of the final, hyper-local distribution. This gives you the best of both worlds: bulk savings combined with targeted, on-the-ground outreach.

Navigating Specialized Logistics

The complexity—and cost—of your last mile multiplies when you need specialized handling. These aren't just minor bumps in the road; they are major cost drivers that have to be baked into your per-kit calculations from day one.

A perfect example is managing cold-chain requirements for something like milk in CACFP multi-day meal kits. This means refrigerated trucks, insulated packaging, and temperature monitoring, all of which add expense and compliance headaches.

Likewise, navigating specific program rules, like designated parent pick-up windows or needing proof of delivery, adds labor and administrative time that shows up directly on your invoice. For organizations trying to scale up, finding smart food program logistics solutions is a critical step to keep these variables from spiraling out of control.

The global food service market is projected to expand from $3.9 trillion in 2025 to $6.5 trillion by 2035, with delivery and takeaway segments expected to dominate at a 55% market share. This powerful consumer trend toward convenience directly impacts how food programs must think about distribution, especially when designing workflows for no-fee home delivery in rural WIC pilots to slash redemption costs and improve access. Discover more insights about the growing food service market at Fact.MR.

Ultimately, designing a cost-effective distribution strategy means you have to pick apart every single step of the journey. By breaking down fulfillment fees, comparing bulk freight against parcel shipping, and planning for the unique demands of your program, you can build a delivery model that works for your budget and for the community you serve. This diligence turns the unpredictable last mile from a budgetary black hole into a manageable, strategic part of your total cost of service.

Uncovering Indirect Costs and Compliance Overhead

While direct costs lay the groundwork for your budget, the expenses that truly shape a sustainable cost of service are often lurking just out of sight. These are your indirect costs and compliance overhead—the absolutely essential, non-negotiable expenses that keep your program running safely, legally, and effectively.

Think of it like running a restaurant. The direct costs are the ingredients you buy for each dish. The indirect costs? That's the rent for the building, the manager's salary, and the electricity bill humming in the background. You can't make a single plate of food without them, but you also can't easily pin their cost to just one meal.

These expenses are the lifeblood of your operation, even if they never physically touch a meal kit. They provide the operational backbone that makes everything else possible. Getting a handle on these costs is the difference between a program that just survives and one that’s truly built to scale and thrive.

Peeling Back Administrative and Facility Overhead

Administrative overhead covers all the people and systems that manage your program but aren't physically packing boxes. This includes the salaries for your program managers, grant writers, and the customer service staff fielding questions from participants. It’s also the cost of the software that tracks inventory (WMS) and the systems that communicate with partners (EDI).

Facility costs fall squarely into this category, too. Beyond the straightforward cost of your warehousing space, a host of other expenses are always running:

- Utilities: The electricity powering your coolers, lights, and office computers.

- Insurance: The liability and property insurance protecting your inventory and operations.

- Maintenance: Routine upkeep for forklifts, conveyor belts, and the facility itself.

These costs are constant, and they have to be factored into every single unit you produce. Ignoring them gives you a dangerously incomplete picture of your financial health.

The Non-Negotiable Cost of Compliance

Compliance overhead is arguably the most critical—and most often underestimated—indirect cost. These aren't optional line items; they are the required investments for participating in regulated food programs and steering clear of hefty penalties. For any organization working within the federal nutrition safety net, this is a major budget item.

For instance, many of the child nutrition programs demand strict adherence to specific rules that generate very real costs. Meeting the USDA's Buy American provision involves extra sourcing diligence and documentation. For Food is Medicine programs, generating detailed outcome reports for healthcare partners requires specialized staff time and software.

Key Insight: Compliance isn't just about following rules; it's a strategic investment in your program's integrity and long-term sustainability. The cost of non-compliance—whether through fines, lost funding, or reputational damage—is always higher than the cost of getting it right from the start.

Managing complex protocols also adds to this overhead. Running an FDA-registered facility with allergen segregation zones, for example, demands meticulous training, separate storage areas, and rigorous cleaning procedures. Each of these necessary steps adds labor and supply costs that must be accounted for. These aren't "extra" expenses—they are fundamental to delivering a safe and compliant service.

How to Calculate Your Per-Unit Cost of Service

Alright, we’ve identified our costs. Now it's time to put them to work by figuring out exactly what it costs to produce a single meal kit or grocery box. This is where the magic happens—moving from abstract budget lines to a concrete, actionable number.

Knowing your true per-unit cost of service is what allows you to build precise budgets, confidently justify your expenses to funders, and negotiate sustainable reimbursement rates. It's the process of taking all your operational spending and neatly assigning a fair share to every single person you serve.

Think of it like splitting a dinner bill with friends. You start by adding up what each person ordered—the entrees, the drinks. Those are your direct costs. But what about the shared appetizer or the tip? You have to figure out a fair way to divide those up, too. Those are your indirect costs. This calculation does the exact same thing for your program.

The Foundational Formula

At its core, the math is refreshingly simple. You just add up all the direct costs that go into one unit and then add a calculated slice of your total indirect costs. The result is a complete, all-in number that represents the genuine expense of delivering that single unit of service.

Total Per-Unit Cost of Service = (Total Direct Costs Per Unit) + (Allocated Indirect Costs Per Unit)

This formula gives you a clear, defensible figure that goes way beyond just the price of food. It ensures that every part of your operation, from the program manager's salary to the warehouse electricity bill, is properly accounted for.

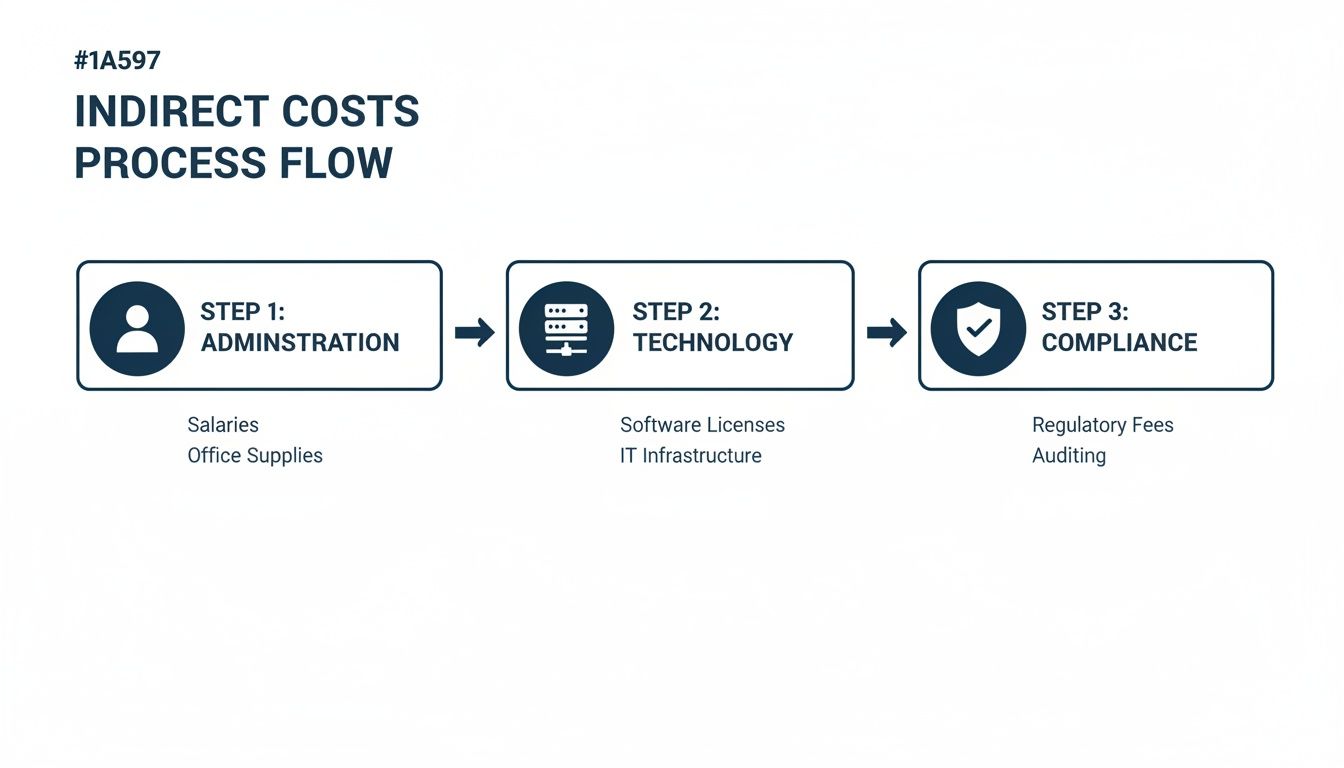

The diagram below shows how all those different indirect costs—administration, technology, compliance—flow into your operational budget. They aren't just separate expenses; they're the foundation supporting every single kit you produce.

As you can see, these administrative, tech, and compliance functions are foundational pillars, not isolated budget lines.

Allocating Your Indirect Costs

The trickiest part of the equation is fairly distributing those shared, indirect costs. How much of your director’s salary or your warehouse management software subscription should be assigned to one SFSP meal kit?

The most common—and effective—method is to calculate an allocation rate.

Here’s a simple, step-by-step way to find yours:

- Sum All Indirect Costs: Add up all your indirect expenses over a set period, like one month. This includes everything from administrative salaries and rent to software fees and compliance overhead.

- Count Total Units Produced: During that same period, count the total number of units you produced or served. This could be meal kits, grocery boxes, or even individuals.

- Calculate the Allocation Rate: Just divide your total indirect costs by your total units produced. The result is the dollar amount of indirect cost you should "allocate" to each individual unit.

Here’s what that looks like in practice:

- Total Monthly Indirect Costs: $20,000

- Total Kits Produced in a Month: 10,000

- Indirect Cost Allocation Rate: $20,000 / 10,000 kits = $2.00 per kit

Simple as that. This means for every kit you assemble, you need to add $2.00 to its direct costs to get to your true cost of service.

Putting It All Together: A Sample Per-Kit Calculation

Let's walk through a real-world example to see how this all comes together. We’ll calculate the cost for a 7-day multi-day meal kit for an SFSP Rural Non-Congregate program.

The table below breaks down how we apply the direct costs and our newly calculated indirect allocation rate to find the total cost of service for a single kit.

Sample Per-Kit Cost Calculation (SFSP 7-Day Rural Kit)

| Cost Component | Example Cost Per Kit | Notes |

|---|---|---|

| Direct Food & Beverage | $18.50 | Includes all USDA-compliant meal components for 7 days. |

| Direct Packaging | $1.25 | Cost of the box, insulation, and packing tape. |

| Direct Kitting Labor | $2.75 | Based on an average time to assemble one kit. |

| Allocated Indirect Cost | $2.00 | Using the allocation rate calculated above. |

| Total Per-Unit Cost | $24.50 | The true, all-in cost to produce and deliver one kit. |

This final $24.50 figure is your North Star. It’s the number you can take to the bank—the one you use to negotiate reimbursement rates with state agencies, build solid grant proposals, and make smart decisions about where you can be more efficient.

Understanding this calculation is more important than ever as the broader foodservice world keeps changing. With consumer spending forecasted to hit $921.7 billion by 2025, operators are feeling the squeeze. Labor and food costs remain top concerns, often eating up 30-35% and 28-33% of expenses, respectively. This pressure makes mastering your own cost of service absolutely essential. You can dig deeper into these foodservice industry trends at Future Market Insights.

Strategies to Optimize Costs and Strengthen Contracts

Understanding your total cost of service is a huge first step, but it’s not the destination. The real magic happens when you turn that knowledge into action. Armed with a precise per-unit cost, you can finally start spotting real opportunities for savings and writing much smarter, more effective contracts.

This is the point where all that analysis turns into a stronger, more sustainable program. You'd be surprised how small operational tweaks can cascade into significant savings. It really comes down to looking at your entire workflow—from the moment product arrives to that final delivery—and asking, "How can we do this better?"

Driving Operational Efficiency

Start with your kitting process. This is often low-hanging fruit. Designing a volunteer-friendly assembly line with simple Standard Operating Procedures (SOPs) is a game-changer for reducing labor costs and boosting output. When the steps are crystal clear, you minimize errors and slash training time, letting you build more kits faster without bloating your payroll.

Logistics is another area ripe for optimization. Instead of defaulting to expensive parcel shipping for every single delivery, it’s time to explore hybrid models. Imagine sending bulk shipments via mixed-truckload freight to regional hubs. From there, your community partners can handle the local distribution. This one move can dramatically cut your last-mile expenses by blending the efficiency of bulk freight with the targeted reach of local delivery.

Key Insight: Optimizing your cost of service isn't about cutting corners on quality; it's about making savvier strategic choices. Every single process, from how a box is packed to how a truck is loaded, is a chance to improve efficiency and reinvest those savings right back into your mission.

Crafting Smarter Procurement and Contract Language

Your cost analysis also becomes your secret weapon at the negotiating table. When you know your numbers cold, you can build partnerships and structure contracts that protect your budget and ensure program integrity from day one. Vague language is the enemy—it almost always leads to unexpected costs and friction later on.

Clarity is your best friend. By getting incredibly specific in your Requests for Proposals (RFPs) and contracts, you set concrete expectations and give yourself a tool to hold partners accountable. This isn't about being difficult; it's about being proactive to prevent costly misunderstandings down the road.

Here are a few practical examples of what this looks like in the real world:

-

For State SFSP Administrators: When writing RFPs for Rural Non-Congregate programs, get granular on home delivery. Explicitly define your proof of delivery standards, spell out parent pick-up rules, and include the exact phrasing required to meet the USDA's Buy American provision.

-

For Food Bank Procurement Managers: In your vendor agreements, build in specific language for forward-buys on OAA-compliant senior items or culturally relevant foods. This helps you lock in pricing before seasonal demand sends costs soaring, giving you much-needed budget predictability.

-

For CPG Partners Evaluating 3PLs: Your service level agreements (SLAs) need to be ironclad on technology. Clearly define requirements for EDI and WMS integrations, lay out allergen-segregated storage protocols, and map out kitting workflows to guarantee the 3PL has the chops to meet your operational demands.

Ultimately, a detailed command of your cost of service is the bedrock for both operational excellence and rock-solid partnerships. It empowers you to refine your processes, eliminate waste, and write airtight contracts that safeguard your resources and amplify your program's impact.

Frequently Asked Questions About Cost of Service

Trying to get a firm grip on program expenses brings up a lot of the same questions for organizations, big and small. The truth is, understanding your cost of service isn't a one-time calculation—it’s an ongoing discipline. This section tackles some of the most common questions managers face when building food programs that are both effective and financially sound.

Think of this as your quick-reference guide. The answers here are direct and designed to help you navigate the typical hurdles and make smarter decisions about your operational finances.

How Often Should We Recalculate Our Cost of Service?

Your cost of service is a living number, not something you can "set and forget." Market conditions, what your suppliers are charging, and your own operational realities just change too fast for a once-a-year review to be enough.

The best practice? Give your numbers a solid review every quarter, and then do a complete, deep-dive recalculation annually. But you should also trigger an immediate recalculation any time a major variable changes, like:

- You sign a new contract with a major supplier.

- Fuel prices jump (or drop) and stay there.

- Your delivery model shifts, say from bulk drops to individual home deliveries.

Keeping this rhythm ensures that your budgets, grant proposals, and any rate negotiations are always built on what’s happening right now, not what was true six months ago.

What Is the Biggest Hidden Cost Most Food Programs Miss?

Without a doubt, it’s compliance overhead. It’s easy to track the price tag on food or a shipping invoice, but the time and resources you pour into just meeting program rules are just as real—and they add up fast.

This is all the staff time that goes into meticulous documentation, pulling together detailed reports for funders like the USDA, managing complex allergen protocols, and making sure your suppliers are adhering to standards like the Buy American provision.

These aren't just administrative tasks; they are a fundamental cost of doing business in the regulated food program space. Getting this wrong can lead to costly penalties or even jeopardize your eligibility.

How Can a 3PL Partner Help Reduce My Overall Cost of Service?

A specialized Third-Party Logistics (3PL) provider can be a game-changer for your total cost of service, mostly through their sheer scale and expertise. Because they handle logistics for so many different clients, they get access to much better rates on shipping and warehousing than you ever could alone. It's a volume game.

But it's not just about bulk discounts. Their expertise in inventory management (using sophisticated WMS/EDI systems), fulfillment, and compliance takes a huge administrative weight off your shoulders. This helps you avoid expensive mistakes, makes your whole operation run smoother, and frees up your team to focus on what they do best: managing your program and serving participants, not wrestling with logistical headaches.

At Umoja Health, we provide the culturally connected foods, compliant meal kits, and expert logistics support that power effective and scalable food programs nationwide. We help our partners master their cost of service from procurement to the last mile. Learn how our solutions can strengthen your program.