When we talk about commercial project management, we're not just talking about getting a project done on time. We're talking about a strategic discipline that ties every single action back to specific financial and business goals.

It’s the crucial bridge between the technical side of a project—the how—and its commercial success, making sure every decision boosts profitability, meets contract terms, and pushes strategic objectives forward.

Why Commercial Project Management Is Non-Negotiable

Can you imagine trying to run air traffic control with nothing but a messy collection of spreadsheets and a chaotic storm of emails? It sounds absurd, but that's exactly how many food programs operate when launching their most critical initiatives.

Without a solid, structured framework, even the best intentions can quickly spiral into confusion, blown deadlines, and very expensive mistakes. This is precisely where commercial project management proves its worth.

It’s not just more corporate jargon; it’s the command center for your entire operation. Think about what it takes to scale up a CACFP meal kit program or launch SFSP Rural Non-Congregate delivery. These aren’t simple to-do lists. They are incredibly complex projects with dozens of moving parts, from navigating federal compliance to managing the intricate dance of cold-chain logistics. A formal approach brings order to that chaos.

Moving Beyond Chaos to Coordinated Action

Without this discipline, teams are stuck in a reactive loop, constantly putting out fires instead of preventing them in the first place. Commercial project management flips that script, shifting the entire focus from crisis management to proactive, confident control.

It works by establishing crystal-clear lines of communication, defining who is responsible for what, and creating a single source of truth that everyone on the project can rely on.

This structured system gets every single stakeholder on the same page and moving in the same direction. From the procurement manager sourcing Buy American-compliant goods to the 3PL partner handling the final mile of delivery, everyone is aligned. Ambiguity is replaced with a clear, actionable roadmap.

A disciplined project management approach is the essential toolkit for preventing costly failures and ensuring compliance. It transforms abstract goals into a concrete plan, making it possible to serve communities effectively and prove program impact to stakeholders.

A Framework for Success and Accountability

At the end of the day, this is all about building a system that guarantees accountability and delivers predictable, repeatable outcomes. It's the engine that ensures resources are used wisely, risks are spotted before they blow up, and goals are hit on time and on budget.

For any organization dedicated to improving nutrition security, a rock-solid project framework isn't a nice-to-have; it's non-negotiable.

This strategic oversight delivers real, tangible benefits that go far beyond just one project:

- Enhanced Compliance: It creates clear, auditable trails and enforces strict adherence to complex regulations like WIC or OAA.

- Improved Stakeholder Confidence: When you have clear reporting and transparent progress, you build incredible trust with funders, state agencies, and community partners.

- Greater Program Impact: By running a tighter ship, more resources—time, money, and energy—can be poured back into the core mission of feeding people.

In the world of large-scale food programs, success is measured in more than just meals delivered. It’s measured in the reliability and integrity of the entire operation. Commercial project management provides the blueprint to achieve both, turning ambitious ideas into measurable, impactful realities.

Building a Rock-Solid Governance Framework

Behind every successful food program is a strong foundation of governance. Without a clear blueprint for who makes the decisions and who is held accountable, even the most well-intentioned projects can veer off course. This can quickly lead to compliance headaches, blown budgets, and a whole lot of confusion among partners.

Governance isn't about creating red tape for the sake of it. It’s about establishing the rules of the road so that everyone—from state agencies to warehouse teams—knows their lane and the project keeps moving forward.

Think of it like building a house. You absolutely need a master architect who designs the structure and makes sure it’s up to code. But you also need a foreman on-site, directing the daily work and making quick calls. Your governance model is what defines how they work together, ensuring information flows smoothly and risks are handled before they become full-blown crises. It’s the very thing that turns a sprawling network of partners into a cohesive, high-functioning team.

Choosing Your Governance Model

In commercial project management, your governance model really comes down to two main styles. Picking the right one hinges on how your organization works and how complex the food program is.

A Centralized Model is like having that single, master architect overseeing the entire job site. A dedicated Project Management Office (PMO) or a lead program director calls the shots, standardizes processes, and acts as the single source of truth. This approach is perfect for massive, complex programs that require tight control over compliance and finances, like rolling out a statewide WIC home delivery pilot.

On the other hand, a Decentralized Model empowers the individual "foremen" on the ground. Project leads within different partner organizations or departments get the autonomy to manage their own piece of the puzzle. This fosters speed and local adaptability, making it a great fit for programs like tailoring CACFP meal kits to specific regional tastes. In reality, many of the most successful programs land somewhere in the middle, using a hybrid approach that combines central oversight for things like compliance with decentralized execution for day-to-day operations.

The most effective governance framework is one that is clearly documented, shared with everyone involved, and consistently followed. It replaces guesswork with clarity, making sure the right people are making the right decisions at the right time.

Defining Roles and Responsibilities

Once you’ve settled on a model, the next crucial step is defining who does what. Gray areas are the enemy of good project execution. A detailed breakdown of roles and responsibilities is the only way to prevent tasks from falling through the cracks and to establish clear lines of accountability.

This goes way beyond just making a list of job titles. It means getting specific about who has the final say on big-ticket items like procurement approvals, budget adjustments, and compliance sign-offs for tricky regulations like Buy American.

A Responsibility Assignment Matrix (RACI) chart is a fantastic tool for this, but even a straightforward table can bring immense clarity. Here’s how roles typically shake out in a large-scale food program.

Key Roles and Responsibilities in Food Program Management

To bring a complex food program to life, you need a diverse team where every player knows their part. The table below outlines the core duties and decision-making power for the key stakeholders who make it all happen.

| Role | Primary Responsibilities | Key Decision Authority |

|---|---|---|

| State Administrator | Ensures program aligns with federal guidelines, manages funding, and oversees vendor contracts. | Approves major program changes, final budget allocation, and compliance reporting. |

| Procurement Manager | Sources food and supplies, manages supplier relationships, and ensures product compliance (e.g., OAA). | Selects vendors, negotiates pricing, and approves purchase orders within budget. |

| 3PL Partner Lead | Oversees warehouse operations, kitting, inventory management, and last-mile delivery logistics. | Manages logistics schedules, oversees cold chain protocols, and resolves delivery issues. |

| Community Org Lead | Coordinates participant outreach, manages distribution sites or enrollment, and gathers feedback. | Determines local distribution schedules and manages volunteer-led kitting efforts. |

By meticulously defining these roles, you build a system where everyone understands exactly how they contribute to the mission. This clarity is the cornerstone of effective commercial project management, giving your team the confidence to execute their duties and ensuring the entire project moves forward as one cohesive unit.

Navigating Compliance and Cold Chain Controls

When you're running government and community food programs, compliance isn't just about checking boxes. It’s the very foundation of trust, safety, and keeping your operation above board.

One slip-up can trigger a failed audit, steep financial penalties, or even worse—a loss of faith from the communities you’ve worked so hard to serve. This is where strong commercial project management turns compliance from a headache into a real advantage.

It gives you the framework needed to get a handle on the complex web of rules, whether you're dealing with Buy American provisions for SFSP kits or tracking inventory for a new WIC pilot. This kind of structured oversight makes sure every box packed and every mile driven hits the highest possible standard of accountability.

Mastering Complex Federal Regulations

Food program regulations can feel like a tangled mess of acronyms and fine print. A project-based approach cuts through the chaos. It lets you build clear protocols for documentation, sourcing, and reporting, which makes being "audit-ready" a normal part of your day-to-day—not a frantic rush to a deadline.

Take the Buy American provision. Proving compliance requires more than just good intentions; it demands painstaking record-keeping that can trace every single product back to its domestic origin. A project manager would set up a dedicated workstream for this, complete with checklists for the procurement team and verification steps for the warehouse crew. The result? Every component in a meal kit is documented and ready for scrutiny.

It’s the same for Older Americans Act (OAA) nutrition guidelines or specific WIC food package rules. You need precise inventory control to get it right. This is where a solid project plan meets a warehouse management system (WMS), creating workflows that stop non-compliant items from being substituted and ensure every senior box or WIC package is assembled perfectly.

Compliance is a non-negotiable element of public trust. When managed effectively, it protects the program, its partners, and the vulnerable populations it serves, ensuring that funds are spent correctly and safely.

The Digital Guardian of Your Cold Chain

For anything perishable, keeping the cold chain intact is everything. It's helpful to think of the cold chain less as a physical space and more as a "digital guardian" that actively protects food from the moment it hits your warehouse to the second it lands on a participant's doorstep. Building and maintaining that guardian is exactly what effective commercial project management does.

This means setting up and watching critical control points across your entire logistics process. We're talking about clear temperature thresholds, strict protocols for pre-cooling refrigerated trucks, and an airtight plan for what to do when something goes wrong. And as you handle more data, understanding the rules around managing subprocessors becomes just as critical to protect data integrity right alongside product integrity.

A well-defined project plan for the cold chain always includes:

- Continuous Monitoring: Putting temperature loggers in storage areas and delivery vehicles to get real-time data and alerts.

- Exception Handling Protocols: A clear, step-by-step plan for when a temperature spike happens. Who needs to be notified? What's the immediate plan to check product safety? At what point is a product considered unsafe?

- Last-Mile Safeguards: Making sure delivery partners follow strict handling rules, like using insulated packaging and confirming that someone is there to receive perishable items promptly.

These protocols are non-negotiable for both food safety and your budget. They prevent the loss of expensive inventory and, most importantly, protect the health of your participants. For organizations needing to build these systems from the ground up, looking into specialized food-grade 3PL and kitting solutions is a smart move. You can learn more about comprehensive logistics solutions designed to tackle these exact challenges.

By treating compliance and cold chain control as dedicated project workstreams, you build a food program that’s resilient, trustworthy, and incredibly effective. It’s a proactive stance that ensures every meal you deliver is not only nutritious but also safe, compliant, and a true reflection of your organization’s commitment to doing things right.

Mapping Your Project From Procurement To Delivery

Every complex food program, no matter how intimidating it seems, can be broken down into a series of connected, manageable workstreams. The secret to successful commercial project management is seeing the entire journey—from sourcing raw goods to the final delivery—as one interconnected system. This mindset turns a daunting initiative into a clear, actionable roadmap.

When operations leaders can trace the full project lifecycle, they gain the power to spot potential bottlenecks before they cause delays. It also helps everyone understand how a decision in one phase will ripple through the next. Let's map this journey from strategic procurement all the way to the last mile.

Phase 1: Strategic Procurement

Long before the first box gets packed, the project lifecycle begins with strategic procurement. This is so much more than just buying food. It's about carefully sourcing components that meet strict compliance standards, like those for Older Americans Act (OAA) senior boxes, while staying on budget and navigating the realities of the supply chain.

A project manager’s first job here is to build a rock-solid procurement workstream. That means creating vendor scorecards, setting firm deadlines for purchase orders, and having contingency plans ready for inevitable stockouts. Every single item has to be tracked against program requirements to guarantee full compliance right from the get-go.

Phase 2: Volunteer-Friendly Kitting Workflows

Once all the components are in the warehouse, the project moves to the next critical phase: kitting. This is where individual items are assembled into finished meal kits or pantry boxes. The efficiency of this stage can make or break your timeline, especially if you're relying on community volunteers.

Good project management here is all about designing workflows that are simple, repeatable, and as error-proof as possible. Think clear standard operating procedures (SOPs), visual packing guides, and quality control checkpoints. For organizations aiming to master this stage, looking into specialized kitting programs for food security can offer a goldmine of best practices for boosting both speed and food safety.

The goal is to make the assembly process so intuitive that a first-time volunteer can be nearly as effective as a seasoned team member. This minimizes errors, maximizes throughput, and keeps morale high.

Phase 3: Technical Integration and Logistics

With the kits assembled, the project shifts into a more technical gear: logistics and data management. This is where a seamless connection between your systems and your third-party logistics (3PL) partner is non-negotiable. The two core technologies that make this happen are Electronic Data Interchange (EDI) and a Warehouse Management System (WMS).

- EDI Integration: Think of this as the digital handshake between your ordering system and your 3PL’s warehouse. It automates the flow of information—from inbound receipts to outbound shipping notices—which kills manual data entry and slashes the risk of human error.

- WMS Integration: A solid WMS gives you real-time visibility into inventory levels, order status, and lot tracking. This is absolutely critical for managing expiration dates, executing a recall if needed, and ensuring every order is accurate.

The project manager's role is to oversee this technical integration, making sure data flows cleanly and that both systems are configured to handle the program’s specific needs, like cold chain temperature monitoring or allergen segregation.

Phase 4: Last-Mile Delivery Challenges

The final—and often most complex—stage is last-mile delivery. Getting a perfectly packed, compliant box to a participant’s doorstep brings its own unique set of challenges, especially for programs like the Rural Non-Congregate Summer Food Service Program (SFSP). In these scenarios, delivery routes can be long and addresses remote.

Effective commercial project management means planning this final step with meticulous care. This workstream requires tight collaboration with delivery partners to optimize routes, set up clear communication protocols for drivers, and create backup plans for failed delivery attempts. For perishable items, it also means guaranteeing cold chain integrity is maintained right up to the moment of delivery.

By mapping out each of these distinct but connected phases, program leaders get a complete, holistic view of the entire operation. This clarity is what allows them to allocate resources effectively, anticipate challenges, and ensure that every single step—from procurement to a participant's front door—is executed with precision and care.

Measuring Success with the Right KPIs and Timelines

In the world of commercial project management, there's an old saying: "If you can't measure it, you can't manage it." This is especially true for food programs. Without clear goals and solid metrics, even the most well-intentioned initiative can get derailed, leading to budget blowouts and a failure to show any real impact.

Success isn't just about counting the total number of meals delivered. It’s about the precision, efficiency, and rock-solid reliability of your entire operation from start to finish.

To truly understand what's working, you have to look beyond simple tallies. Real success is defined by Key Performance Indicators (KPIs) that paint a complete picture of your program's health. These numbers provide the hard data needed to prove your effectiveness to stakeholders—from state vendor managers to health plan directors—and help you make smart, data-driven decisions that improve service over time.

A critical first step is knowing how to develop key performance indicators that genuinely reflect your project's goals.

Core KPIs for Food Program Management

To get meaningful insights, your team should lock in on a handful of crucial KPIs that track efficiency, accuracy, and financial stewardship. These metrics turn abstract goals into tangible targets that drive accountability across the board.

Here are the big three:

- On-Time In-Full (OTIF) Rate: This measures the percentage of orders delivered on the correct date with all the right items in the right quantities. An OTIF rate of 98% or higher is the gold standard and signals a highly reliable supply chain.

- Order Accuracy Rate: This KPI zeroes in on what’s inside each package. It tracks the percentage of orders shipped without any errors like missing items, incorrect substitutions, or damaged goods. It’s a direct measure of your quality control during kitting and fulfillment.

- Cost-Per-Meal/Kit: This one is straightforward: divide the total program cost by the number of units delivered. This gives you a clear financial benchmark, which is essential for budget forecasting, showing fiscal responsibility to funders, and spotting opportunities to save money.

These KPIs are the bedrock of an effective reporting system. They allow you to create dashboards tailored to different stakeholders. For instance, a state administrator might focus on compliance and OTIF rates, while your internal operations lead will be watching order accuracy and kitting cycle times like a hawk.

By tracking the right metrics, you move from simply running a program to strategically managing an investment in community health. Data becomes your most powerful tool for continuous improvement and proving your impact.

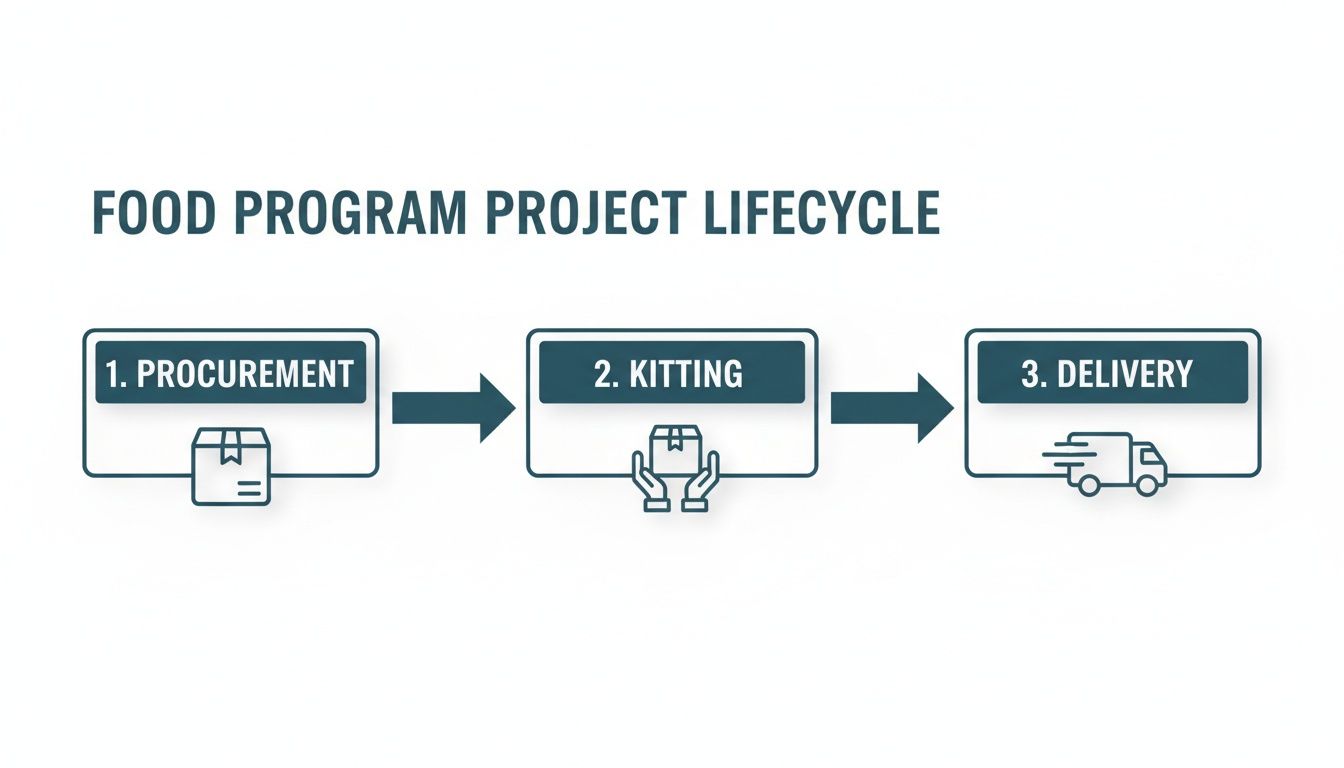

The visual below maps out the typical project lifecycle for these food programs. It shows how each stage—procurement, kitting, and delivery—has to be managed tightly to hit those critical KPIs.

This flow makes it clear that success is a chain reaction. A delay in procurement directly messes with the kitting schedule, which then torpedoes your on-time delivery rates. It's all connected.

Now, let's break down those essential KPIs in a bit more detail.

Essential KPIs for Food Program Project Management

Tracking the right data is the only way to know if your food security initiative is truly succeeding. The table below outlines the core metrics, what they measure, and why they are so critical for demonstrating impact and driving operational improvements.

| KPI | What It Measures | Why It Matters |

|---|---|---|

| On-Time In-Full (OTIF) Rate | The percentage of orders delivered on the correct date, with the correct items and quantities. | This is the ultimate measure of reliability. A high OTIF rate builds trust with participants and stakeholders, proving your supply chain is dependable. |

| Order Accuracy Rate | The percentage of orders shipped with zero errors (e.g., no missing items, wrong products, or damage). | This directly reflects the quality of your fulfillment process. High accuracy reduces waste, prevents participant complaints, and protects your program's reputation. |

| Cost-Per-Meal/Kit | The total program cost divided by the number of units delivered. | This is your core financial health metric. It’s crucial for budgeting, securing funding, and identifying opportunities to make your program more efficient. |

| Participant Satisfaction Score | Feedback collected from participants regarding their experience with the program, often on a scale of 1-10. | This tells you if the program is meeting the needs of the people it's designed to serve. It provides qualitative data to complement your operational metrics. |

| Inventory Turnover Rate | How many times inventory is used and replaced over a specific period. | This KPI helps you manage perishable goods effectively, minimize waste from expired products, and ensure you're not tying up capital in excess stock. |

| Compliance Adherence Rate | The percentage of operations that meet all regulatory requirements (e.g., Buy American, WIC, OAA). | For government-funded programs, this is non-negotiable. It ensures you maintain funding and avoid legal or financial penalties. |

By consistently monitoring these KPIs, you gain a 360-degree view of your program, enabling you to pinpoint weaknesses and build on your strengths.

A Sample 12-Week Launch Timeline

To put this into a real-world context, here’s a high-level, 12-week timeline for launching a new 'Food is Medicine' grocery program. Think of it as an adaptable roadmap for your own initiatives.

Phase 1: Foundation and Planning (Weeks 1-4)

- Week 1: Finalize the project charter, get sign-off from all key stakeholders, and define your core KPIs.

- Week 2: Lock in the governance framework and confirm everyone's roles and responsibilities. No ambiguity allowed.

- Week 3: Complete vendor selection for both food procurement and your 3PL logistics partner.

- Week 4: Finalize the menu or box contents and build out the initial budget and risk register.

Phase 2: Setup and Integration (Weeks 5-8)

- Week 5: Kick off EDI/WMS integration with your 3PL partner and start the procurement process.

- Week 6: Develop and document all kitting SOPs and create your quality control checklists.

- Week 7: Configure the reporting dashboards and thoroughly test the data flow for all your KPIs.

- Week 8: Conduct a small pilot run of the entire kitting and delivery process with a test group.

Phase 3: Launch and Optimization (Weeks 9-12)

- Week 9: Begin full-scale participant enrollment and start the first wave of food deliveries.

- Week 10: Monitor KPIs in real-time and hold daily check-ins to jump on any issues immediately.

- Week 11: Gather initial feedback from participants and make any necessary adjustments to delivery schedules or communication.

- Week 12: Hold a post-launch review meeting, document all lessons learned, and start refining your processes for the next cycle.

This structured timeline ensures all the critical tasks get done in a logical order, turning what could be a chaotic launch into a manageable and measurable project.

Frequently Asked Questions

When you start moving toward a more structured approach, a lot of practical questions pop up. This section gives you direct, real-world answers to the most common questions we hear about bringing commercial project management into food programs. The goal is to help you clear the usual hurdles and get moving.

How Can We Adopt This Without a Large Budget?

You can absolutely embrace the principles of commercial project management without buying expensive software. The secret is to focus on the process first, and the tools second. Kick things off by creating a clear project charter—a simple document that defines the scope, goals, and who is responsible for what.

Then, use free or existing tools to map out a master timeline highlighting your critical milestones. Imagine a CACFP sponsor managing 50 sites. A shared project plan that details menu deadlines, procurement schedules, and delivery windows can slash errors and keep service on track, all without needing a dedicated project manager or a fancy software subscription.

What Is the Most Critical Document to Start With?

Without a doubt, the single most important document is the Project Charter (sometimes called a Statement of Work or SOW). Think of this as your project's constitution. It's the ultimate source of truth when disagreements or confusion inevitably come up.

This foundational document has to outline clear objectives (like "deliver 10,000 OAA-compliant senior boxes in Q1"), define the project's scope, identify every key stakeholder, and get a formal sign-off. For something like a WIC home delivery pilot, the charter would lock in eligible ZIP codes and approved food substitution rules, preventing costly misunderstandings later on.

This one document aligns everyone on the "what" and the "why" before a single box is packed. It’s the bedrock of successful commercial project management, turning ambiguity into a shared, agreed-upon mission.

How Should Our Plan Account for Supply Chain Risks?

A strong project plan doesn't just hope for the best; it anticipates disruptions from day one. Your first step should be a thorough risk assessment to pinpoint potential nightmares, like a major supplier recall, a crippling blizzard, or unexpected freight delays.

For each high-probability risk, you need a specific mitigation plan. This isn't about being pessimistic—it's about being prepared. Your plan might include:

- Pre-qualifying backup suppliers for critical food items.

- Building a two-week buffer into your procurement timeline.

- Negotiating standby agreements with a secondary logistics provider for emergencies.

This level of foresight is what separates successful programs from struggling ones. In fact, poor project execution is incredibly costly. It's estimated that organizations lose roughly 9–11% of every dollar invested in projects due to benefit shortfalls or cost overruns. For food programs, that translates directly into fewer families served.

Despite the high stakes, only about 23% of organizations use dedicated project management software, with most still trying to run complex initiatives on spreadsheets. Learn more about these project management statistics to see why a structured approach matters.

At Umoja Health, we provide the tools, culturally connected foods, and logistical expertise to help you run compliant, efficient, and impactful food programs at scale. Discover how our end-to-end solutions can transform your operations by visiting us at https://umojahealth.com.