When a disaster strikes, access to fresh food and cooking facilities disappears in an instant. This is where disaster relief meal kits become absolutely essential. They are pre-packaged, shelf-stable food supplies designed for rapid deployment, providing critical nutrition when it's needed most. These kits range from simple ready-to-eat meals to more advanced self-heating options for the toughest conditions. The goal is always the same: deliver safe, sustaining calories to affected people, fast.

Designing Meal Kits That Actually Work in the Field

The foundation of any successful disaster response is a thoughtfully designed meal kit. It’s so much more than just calories in a box; it’s a lifeline for survival and comfort in the immediate aftermath of a crisis. Getting these kits right requires a careful balance of nutrition, logistics, and compliance to ensure they're effective when the stakes are highest.

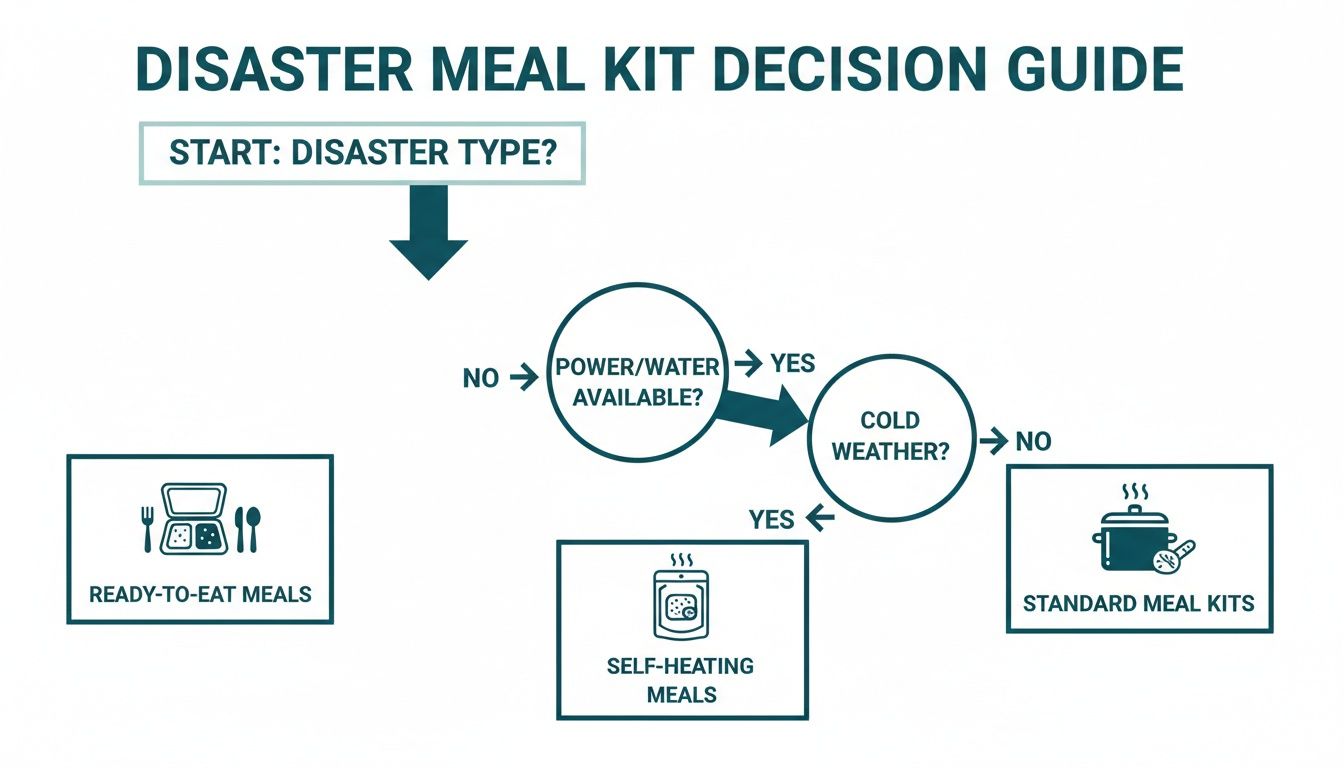

Right out of the gate, you face a major decision: do you go with ready-to-eat (RTE) or self-heating meals? This choice is dictated entirely by the operational environment of the disaster.

Ready-to-Eat vs. Self-Heating Kits

Ready-to-eat meal kits are the undisputed workhorses of disaster relief. They require no external heat source, no water, and no special equipment. This makes them perfect for scenarios where infrastructure is completely wiped out, like after a hurricane or a major earthquake. Their simplicity means anyone can get the nutrition they need immediately, which is vital in that critical first 72-hour window.

Self-heating kits, on the other hand, offer the incredible morale boost of a hot meal. This is a game-changer in cold-weather emergencies like winter storms or blizzards. The integrated flameless ration heater provides warmth and a sense of normalcy, but it's important to remember that this feature adds weight, cost, and a bit more complexity to each kit.

So, how do you decide? Think about the conditions on the ground.

This flowchart really simplifies the decision. When power and water are out, ready-to-eat kits are your go-to. Self-heating options are best reserved for those cold environments where warmth is just as critical as calories.

To make the comparison even clearer, here's a quick breakdown of the two main types of disaster meal kits.

Ready-to-Eat (RTE) vs Self-Heating Meal Kits

| Feature | Ready-to-Eat (RTE) Kits | Self-Heating Kits | Best Use Case |

|---|---|---|---|

| Preparation | None needed; open and eat | Activate heater with a small amount of liquid | RTE: First 72 hours, widespread infrastructure failure. Self-Heating: Cold weather, prolonged power outages. |

| Logistics | Lighter, simpler, lower cost per unit | Heavier, more complex, higher cost | RTE: Large-scale, rapid deployments. Self-Heating: Targeted relief for vulnerable populations in cold climates. |

| Morale | Provides basic sustenance | Hot meal provides significant psychological comfort | RTE: Mass feeding operations. Self-Heating: Improving well-being during stressful, cold emergencies. |

| Equipment | No external equipment required | Flameless ration heater included in the kit | RTE: Situations with no power, water, or supplies. Self-Heating: When a warm meal is a priority for health and morale. |

Ultimately, the choice between RTE and self-heating kits depends entirely on the specific disaster scenario, logistical capabilities, and the primary needs of the affected population.

Building a Compliant and Resilient Supply Chain

Beyond just the type of meal, sourcing high-quality, durable components is absolutely non-negotiable. Every single item in that box must meet stringent shelf-life standards, typically 24-36 months, to allow for pre-positioning and long-term storage. The packaging has to be tough enough to withstand rough handling, airdrops, and exposure to the elements without compromising food safety.

Navigating the web of compliance is just as crucial for agencies and their partners. You have to be aware of regulations like:

- The Older Americans Act (OAA), which sets specific nutritional guidelines for meals served to seniors.

- Buy American Provisions, mandating the use of domestically sourced food and components for federally funded programs.

- CACFP/SFSP guidelines for any kits intended for children, ensuring they meet established nutritional benchmarks.

This regulatory landscape ensures the food provided is not only safe but also appropriate for the people being served. Building a supply chain that can meet these standards while also scaling rapidly during a surge in demand is a massive logistical challenge. The global emergency food kit market was valued at USD 1.59 billion in 2024 and is projected to hit USD 2.90 billion by 2035, reflecting a clear trend toward higher-quality, nutrient-fortified meals even in crisis scenarios.

A Lesson from the Field: During one response, a batch of donated granola bars melted into an unusable sticky mess because the packaging wasn't rated for the high heat inside a storage container. This taught us a critical lesson: every single component, down to the wrapper, must be stress-tested for real-world disaster conditions.

A successful kit is one that considers the entire journey, from procurement to consumption. When you're designing kits, especially those with any perishable items, you have to understand the risks of reefer breakdown during transport. Even shelf-stable items can be compromised by extreme temperature swings. For more specialized needs, it’s also worth looking into how themed meal kits can support diverse communities with culturally relevant food, which can dramatically enhance their effectiveness and acceptance.

Agile Development for Rapid Disaster Response

Traditional product development cycles don’t work in a crisis. An agile approach is essential, enabling real-time adaptation of disaster relief meal kits as conditions evolve. This isn't about creating one perfect kit; it’s about building a flexible system designed for rapid iteration and deployment. True agility means maintaining a core, universally accepted kit while having a modular inventory of supplemental items ready to deploy at a moment's notice.

Umoja's Lessons from the Field: The Modular Approach

Experience taught us that a one-size-fits-all strategy fails to meet specific community needs. During one response, we received feedback that our standard can openers were difficult for seniors with arthritis. Within 48 hours, our procurement team sourced easy-twist models, and our kitting line integrated them into all outgoing kits. This small adjustment significantly improved accessibility and dignity for a vulnerable group.

Our biggest breakthrough has been developing pre-kitted supplemental modules. Instead of managing dozens of unique kit configurations, we maintain a standard core kit and pre-pack separate modules for diabetic, low-sodium, infant, or culturally specific needs. This allows us to customize an entire truckload just hours before deployment, precisely matching the demographic needs of an affected area with incredible speed.

This modular system is the cornerstone of our agile product development. It allows us to respond to real-time intelligence from the ground without redesigning our entire workflow.

Umoja’s Step-by-Step Emergency Protocol

Our protocol is built for speed, clarity, and adaptability. It’s a living system we refine after every activation.

Hours 0-3: Immediate Needs Assessment

The moment a disaster is confirmed, our logistics leads connect with partners on the ground. We focus on three core data points: the affected population's demographics, the status of critical infrastructure (power, water), and any immediate, specific dietary needs (infants, seniors, medical conditions). This initial intelligence dictates the precise ratio of core kits to supplemental modules required.

Hours 3-6: Parallel Supply Chain Activation

Our Warehouse Management System (WMS) provides a live inventory of all components. Simultaneously, our procurement team activates our emergency vendor list, contacting pre-vetted suppliers to secure any critical items flagged in the needs assessment. Running these tasks in parallel eliminates critical wait times and accelerates our readiness.

Hours 6-12: Kitting Line Mobilization

We activate a pre-planned kitting line designed for maximum throughput. Each station has clear visual instructions, minimizing training time for volunteers. Our trained supervisors oversee the line, ensuring quality control and tracking component lot numbers for complete food safety and traceability.

Hours 12-24: Dynamic Logistics and Deployment

While kits are being assembled, our logistics team finalizes transport. They confirm primary, secondary, and tertiary routes, coordinate with multiple carriers, and prepare all shipping documentation. This proactive planning anticipates roadblocks and ensures we have viable contingency routes mapped before trucks ever leave the warehouse.

This agile protocol allows us to shape our disaster relief meal kits to meet the true, evolving needs of a community, transforming a simple box of food into a powerful and responsive relief tool.

Developing a First 72 Hours Deployment Strategy

In a crisis, the first 72 hours are a dead sprint. Success isn't about improvising on the fly; it’s about activating a battle-tested strategy that moves with purpose and speed. This is where a truly agile deployment model becomes your single greatest asset, turning your warehouse from a static depot into a dynamic launchpad for immediate relief.

This agility is baked in long before a storm ever makes landfall. It starts with a clear-eyed assessment of your operational capabilities and the hard-won lessons from past events. A plan that looks perfect on paper can completely fall apart when faced with impassable roads or downed communication networks. Our entire approach is built on flexibility, ensuring our disaster relief meal kits get where they need to go, no matter what.

The goal is to marry structure with adaptability. You need a clear, sequential plan, but one with the built-in flexibility to pivot based on what’s actually happening on the ground. It’s a disciplined process that anticipates points of failure and has contingencies ready before they're even needed.

Umoja's Lessons from Rapid Response

Our experience in the field has taught us one thing above all else: you can never over-prepare for that initial deployment push.

During one coastal hurricane response, our primary distribution hub was completely cut off by flooding within 12 hours. Because we had pre-staged assets at a secondary inland location, we were able to reroute trucks and keep the meal kits moving with minimal delay. That event cemented our belief that decentralized, pre-positioned assets are a non-negotiable part of any serious deployment strategy.

Our Critical Finding: The single biggest point of failure in the first 72 hours is transportation. Establishing clear primary, secondary, and even tertiary transport routes—and having agreements with multiple carriers—is the difference between a successful deployment and a warehouse full of supplies that can't reach anyone.

This is why we treat logistics planning with the same urgency as kit assembly. We map out potential staging areas, identify vetted local transport partners, and establish communication protocols that don't rely on cellular networks. This groundwork is what enables a truly nimble response when every single minute counts.

Step-by-Step Emergency Protocols

To put these lessons into action, we've developed a set of emergency protocols that guide our team from the moment an alert is issued. Think of it less as a rigid checklist and more as a flexible framework for moving assets swiftly and intelligently.

-

Asset Pre-Positioning: Based on seasonal risk assessments (like hurricane season on the Gulf Coast), we move a calculated inventory of disaster relief meal kits to strategically located partner warehouses. This simple step can shave days off of transit times when a disaster is imminent.

-

Load Plan Activation: We maintain pre-built load plans for different truck sizes and disaster scenarios. A "First-72-Hour" plan for a flood zone will prioritize ready-to-eat meals and bottled water, while a cold-weather plan will feature more self-heating kits. This removes the guesswork from the high-stress deployment phase.

-

Real-Time Route Mapping: Our logistics team uses live traffic and infrastructure data to map the safest, most efficient routes. We identify potential chokepoints and brief drivers on alternative paths before they leave the warehouse, empowering them to make smart decisions on the ground.

-

Communication Redundancy: We set up multiple lines of communication with our field teams and transport partners, including satellite phones and radio channels. This ensures that even if primary systems fail, we maintain command and control over the entire deployment.

This structured, adaptive approach is critical for any organization involved in large-scale disaster response. The North American emergency food market commands a dominant 41.3% share of the global market, a figure driven by the proven need for rapid, effective food distribution. During Hurricane Katrina, ready-to-eat meals made up over 50% of all food aid, highlighting their logistical superiority in a crisis. This is a clear indicator that preparedness and efficient supply chains are what truly make a difference on the ground.

Executing an Agile Response in a Crisis

In the middle of a disaster, the best-laid plans can fall apart in minutes. Roads get washed out, supply lines break, and a community's needs can shift with every passing hour. This is exactly where a rigid, top-down strategy crumbles and an agile, adaptive one saves the day.

Running an agile response doesn’t mean you throw your plan out the window. It’s about having a system built for rapid change. It's the art of balancing a clear, established protocol with the flexibility to pivot based on what you’re hearing from the ground. This mindset turns a static supply chain into a living, breathing response engine, making sure the right aid gets to the right people when they need it most.

The Power of Rapid Feedback Loops

The absolute cornerstone of agility is communication. You have to establish a direct, constant feedback loop between your logistics hub and the teams in the field. It’s non-negotiable. This constant flow of information allows you to modify disaster relief meal kits and shipping plans on the fly, reacting to what’s actually happening, not what you assumed would happen.

For example, during a tornado response, initial reports didn’t flag the large number of families with infants in temporary shelters. But feedback from a field partner quickly alerted us to a critical need for baby formula and food. Because our system was designed for this, our procurement team was able to source and dispatch these specific items on the very next truck, folding them right into our distribution.

Umoja’s Hard-Won Lesson: Never assume the initial plan is the final plan. The most valuable asset in any disaster is real-time intelligence from the ground. Building a protocol that not only accepts but expects to be modified is the key to an effective response.

This constant cycle of listening, adapting, and executing is what separates a good response from a great one. It’s a candid, real-world approach to innovating under the most extreme pressure.

Umoja’s Emergency Protocol: A Step-by-Step Guide

Our experience has helped us forge an emergency protocol that blends structure with the need for on-the-fly decision-making. It’s a framework that allows us to move with speed and precision, from the initial alert to final deployment.

Phase 1: Activation and Assessment (Hours 0-4)

The moment a crisis is confirmed, our response team activates. The first move isn’t to start packing boxes; it's to gather intelligence. We immediately connect with on-the-ground partners to get answers to critical questions:

- What is the estimated number of people affected?

- Is there access to clean water and power?

- Are there immediate, specific needs (e.g., infant supplies, medical dietary requirements)?

This rapid assessment directly informs our initial deployment strategy and ensures we aren’t sending the wrong resources.

Phase 2: Procurement and Kitting Mobilization (Hours 4-12)

With initial data in hand, two things kick off at once. Our procurement team contacts pre-vetted emergency suppliers to lock down any high-demand items we just identified. At the exact same time, we mobilize our kitting line, often staffed by dedicated volunteers.

We learned the hard way that complexity is the enemy of speed. Our kitting stations are designed with simple, visual instructions, which means a new volunteer can be up and running in minutes. This parallel processing—procuring and kitting simultaneously—dramatically compresses our response timeline. In past efforts, this has allowed us to stand up a fully operational kitting line in under 24 hours, a critical capability when every hour counts.

Phase 3: Logistics Pivot and Deployment (Hours 12-24)

While kits are being assembled, our logistics team is in constant motion. They are not just booking trucks; they are war-gaming the transit itself. Primary routes are mapped out, but more importantly, so are secondary and tertiary routes in case of blockages.

During one wildfire response, the main highway into an affected town was suddenly closed. Because our logistics team had already mapped an alternative route on smaller service roads and briefed the driver on the backup plan, the shipment of disaster relief meal kits was only delayed by a few hours, not days. This kind of proactive planning is what agile deployment is all about. This mindset transforms logistical challenges from showstoppers into solvable problems, ensuring aid keeps flowing.

From Data Logs to Debriefs: Sharpening Your Next Response

When the last truck of disaster relief meal kits finally pulls away, the work isn't over. In many ways, it’s just beginning. The data collected during the chaos of a response is where the real learning happens—transforming from simple records into your single most valuable asset for the next time.

This is the point where we move beyond gut feelings and anecdotal evidence. Solid data allows you to pinpoint exactly what worked, what broke down, and where the bottlenecks were. It's the only way to build a cycle of continuous improvement that makes each response faster, smarter, and more impactful than the last.

The Metrics That Actually Matter

When you're swimming in data, it’s easy to get lost. You need to focus on a handful of crucial metrics that tell the real story of your operation. These are the numbers that will form the backbone of your after-action reports and your internal debriefs.

- Kits Distributed Per Day: This is your gut check on speed and efficiency. It tells you how well your last-mile distribution network is performing under pressure.

- Logistical Cost Per Meal: This one is all about stewardship. By tracking transport, warehousing, and labor costs against the meals delivered, you can find real opportunities to make every dollar go further.

- Populations Served: Who did you actually reach? Documenting demographics—like the number of children, seniors, or those with specific medical or dietary needs—is critical for tailoring future meal kits and deployment strategies.

Tracking these KPIs isn't just about making charts for a PowerPoint presentation. It's about understanding the real-world friction in your system and finding ways to smooth it out before the next crisis hits.

Turning Numbers into Action

The true value of this data comes out in the post-event debrief. This is where your team comes together—logistics, field ops, procurement—to have an honest conversation about the numbers and the stories behind them. The goal is to get from "what happened" to "how we make sure that doesn't happen again."

For example, if your data shows a stubbornly high cost-per-meal, the debrief might uncover that your team relied on a single, congested transport route. The fix? An actionable plan to map out and pre-approve secondary and tertiary routes for all future deployments.

Or maybe feedback from shelters reveals that a particular item in your kits consistently went uneaten. That's a direct signal to refine your pack list, cut waste, and better meet the actual needs of the people you're serving.

This cycle of action, data collection, and refinement is what separates good organizations from great ones. With the global emergency food market projected to grow by USD 5,376.7 million between 2025 and 2029, driven largely by climate-related disasters, operational excellence is no longer optional. You can explore detailed emergency food market analysis from Technavio to get a deeper sense of these trends.

A Lesson from Our Debriefs: After one response, our data showed a significant number of our disaster relief meal kits were delivered a full day later than projected. The debrief traced the delay back to a single distribution hub that became overwhelmed. Our solution was to create a new SOP for activating multiple, smaller staging areas simultaneously, decentralizing our logistics to build resilience.

To help structure this process, we've found it incredibly useful to standardize the metrics we track and report on. A consistent framework ensures that no critical piece of information gets lost in the shuffle and allows for easier comparison between different response efforts over time.

Essential Post-Disaster Reporting Metrics

Here is a summary of the key performance indicators (KPIs) we recommend tracking during and after a disaster relief operation. This framework provides the data needed for effective reporting and robust future planning.

| Metric Category | Key Performance Indicator (KPI) | Purpose of Tracking |

|---|---|---|

| Distribution Efficiency | – Kits Distributed Per Day/Week – Average Delivery Time from Hub to Field |

Measures the speed and throughput of the last-mile logistics network. |

| Cost Management | – Logistical Cost Per Meal – Warehousing Cost as % of Total |

Identifies opportunities for financial efficiency and better resource allocation. |

| Inventory & Supply Chain | – Inventory Accuracy Rate – Order Fill Rate |

Assesses the reliability and accuracy of warehousing and supply chain operations. |

| Beneficiary Impact | – Number of Individuals Served (by demographic) – % of Kits Meeting Specific Dietary Needs |

Ensures the response is effectively reaching and meeting the needs of the target population. |

| Operational Performance | – Volunteer/Staff Hours Per 1,000 Kits – Vehicle Utilization Rate |

Gauges the efficiency of labor and asset deployment during the response. |

By treating every deployment as a chance to learn and systematically upgrading your SOPs based on hard data, you build a more agile, resilient, and effective disaster relief program. This isn't just about improving operations; it's about delivering help faster and more effectively to people when they need it most.

Common Questions from the Field

When you're in the thick of a disaster response, theory goes out the window. Logistics managers and emergency teams on the ground need straightforward answers to tough questions. Here are a few of the most frequent ones we hear, based on our years of experience.

How Do We Handle Common Dietary Restrictions?

This is a huge one, and planning for it upfront is non-negotiable. The best approach we've found is to make your standard disaster relief meal kits as universally friendly as possible right from the start. That means deliberately sourcing components that avoid common allergens like tree nuts and dairy.

For everything else, you'll want a smaller, separate inventory of specialized kits. Think gluten-free, low-sodium, or diabetic-friendly options. The critical part? These kits have to be aggressively labeled—bold, clear, impossible to miss—so there are no mix-ups in the chaos. You don't send these out blindly; they're deployed based on specific requests from field teams who know the actual needs of a particular shelter or community.

What's the Single Biggest Logistical Mistake to Avoid?

Easy. Putting all your eggs in one basket by relying on a single distribution point. It's the most common and damaging mistake we see. A single blocked road, a power grid failure, or a security issue at that one hub, and your entire relief effort grinds to a halt. You've created a critical point of failure.

A much more resilient strategy is to build a decentralized distribution model from day one. That means pre-identifying and vetting multiple secondary, and even tertiary, staging areas before a disaster ever hits. Working with smaller, dispersed hubs gives you agility. It lets you reroute supplies and keep aid flowing even when your primary location gets knocked out.

Our Field Insight: In one response, our main warehouse was completely cut off by flash flooding. We were able to divert incoming trucks to a pre-arranged partner facility 50 miles away and kept operations running with almost no delay. That decentralized model is now a core part of our protocol. It's a lifesaver.

How Can We Best Use Volunteers for Kitting Operations?

Volunteers are the heart and soul of so many relief efforts, but their energy needs to be channeled effectively. To get the most out of them, set up a simple, highly visual assembly line. Each station should have its own clear instructions—use pictures and minimal text showing exactly what goes into the box at that specific step.

Here's the real pro-tip: pre-pack the component boxes for each station before your volunteers even walk in the door. It's a small step that eliminates a massive amount of confusion and keeps the line moving. Your trained staff shouldn't be on the line; they should be floating, acting as supervisors, doing quality control, and keeping morale high. This structure keeps things efficient and accurate, even with a large group of well-intentioned but untrained people.

What's a Realistic Shelf Life for These Meal Kits?

You should be aiming for a minimum shelf life of 24 to 36 months for a standard disaster relief kit. But getting there isn't about just picking a date. The whole kit is only as good as its shortest-dated component, so it's a constant balancing act.

This means you have to be meticulous about sourcing. Items like water pouches and canned goods can last for years and can be bought well in advance. But things like energy bars, crackers, or fruit cups have much shorter windows. You'll need a rock-solid first-in, first-out (FIFO) rotation system in your warehouse to make sure the final assembled kit hits your target without any waste.

At Umoja Health, we build compliant, agile, and effective food programs for disaster response because we've been there. Our team can help you design and deploy disaster relief meal kits that actually work in the real world. Contact us to learn how we can support your preparedness efforts.