When a crisis hits, theory goes out the window. All that matters is the ticking clock of real-world logistics. For emergency food distribution services, an operational plan isn't a nice-to-have; it's the only way to move from abstract ideas to getting food into the hands of people who need it. This playbook is our boots-on-the-ground perspective, built from Umoja's experience organizing and scaling massive food responses.

The Reality of Emergency Food Response

In the chaos following a disaster, the first few hours are absolutely critical. The difference between an effective response and a failed one almost always comes down to how solid your plan was before the emergency.

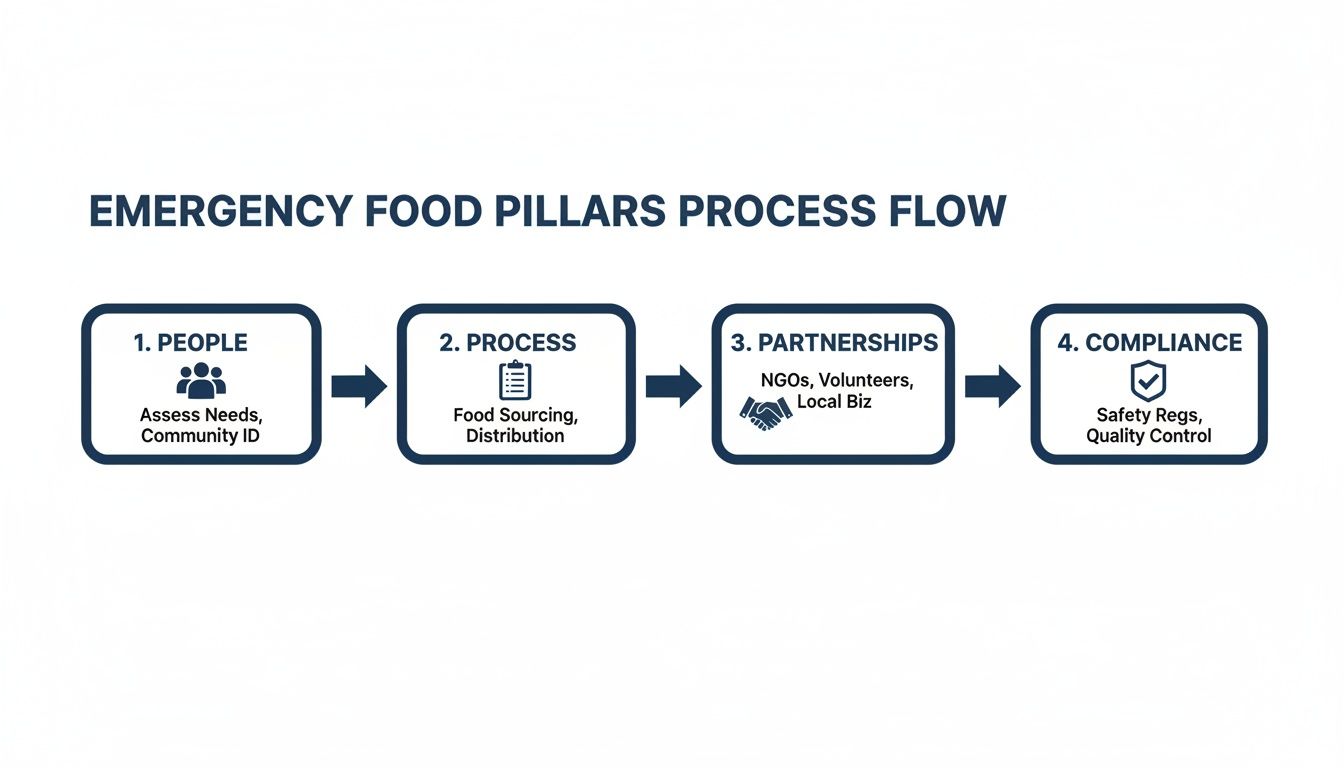

It's not just about having a warehouse full of food. It's about a system ready to activate at a moment's notice—a system that gets the four core pillars of a successful operation right: people, process, partnerships, and compliance. Without that clear framework, even the most well-intentioned efforts will buckle under the immense stress of a real-world crisis.

Here at Umoja, our experience in the field has taught us that a successful response is built long before the disaster ever strikes. It’s about creating a living document that anticipates needs and outlines clear, actionable steps for everyone, from logistics chiefs to the volunteers on the ground.

The Four Pillars of a Successful Operation

An effective emergency food strategy rests on four interconnected pillars. If one is weak, the whole structure is at risk.

- People: You need a pre-identified rapid-response team, trained volunteers, and crystal-clear leadership roles. Who makes the final call on inventory? Who manages volunteer check-in? These questions must be answered before the phones start ringing.

- Process: This is your tactical playbook. It has to cover everything from activating your program and setting up a command center to managing inventory and figuring out that tricky last-mile delivery. Clear Standard Operating Procedures (SOPs) are what prevent confusion when stress is sky-high.

- Partnerships: No one can do this alone. Strong, pre-negotiated relationships with government agencies, Community-Based Organizations (CBOs), and suppliers are absolutely vital. These partnerships create a coordinated response, not a competitive one.

- Compliance: This is the bedrock of a sustainable and auditable program. From sticking to Buy American clauses in government contracts to following strict cold-chain rules for perishable goods, compliance ensures safety, equity, and accountability.

A detailed operational plan is what transforms chaos into a coordinated effort. It ensures that when a community is at its most vulnerable, your organization can deliver life-sustaining food with efficiency and dignity.

This guide is built for the program administrators, food bank managers, and logistics chiefs on the front lines. We'll break down each of these pillars into concrete actions you can put into practice right away.

For a deeper look into the operational challenges and successes of actual emergency food provisioning, check out these real-world examples of feeding efforts during hurricane relief. By understanding these core components, you can build a more resilient system.

Learn more about how Umoja Health helps government agencies and community partners prepare for and execute effective disaster response operations.

Your Zero-Hour Mobilization Plan

When an emergency alert hits, the clock starts. Those first few moments of a crisis are no time for strategy sessions or debates; they demand immediate, decisive action. This is where your zero-hour mobilization plan comes in—it's the trigger that shifts your entire operation from standby to active deployment.

It's all about having a pre-defined protocol that everyone on your rapid-response team knows inside and out. This lets you move people and assets within minutes, not days. At Umoja, we see this as the foundational sprint that sets the pace for the entire marathon of disaster response.

The urgency here is driven by a stark reality. Globally, we've seen a 20% surge in acute food insecurity since 2020, with conflict and climate change cranking up the pressure in hotspots worldwide. This sharp increase highlights just how critical efficient emergency food distribution services are. For a deeper dive, the latest World Bank food security update lays out these escalating challenges in detail. A well-rehearsed plan is what ensures this global need is met with an effective, local response.

Assembling Your Rapid-Response Core

Your very first move is to get your rapid-response team assembled. This is not the moment to be figuring out who’s in charge. Your plan needs a crystal-clear roster with primary and secondary contacts for every key role.

- Logistics Chief: This person is your quarterback. They’re the one triggering pre-negotiated contracts with suppliers and 3PL partners, confirming warehouse readiness, and overseeing the initial truck load-outs.

- Communications Lead: They get a command center up and running, manage all communications (internal and external), and keep every stakeholder in the loop with consistent updates.

- Volunteer Coordinator: This individual activates the volunteer call list, sets up a check-in point (whether that’s physical or virtual), and starts assigning initial tasks like kitting or site setup.

These roles must be empowered to make decisions on their own within their defined areas. Micromanagement in a crisis creates bottlenecks, and bottlenecks cost precious time.

A successful mobilization isn't just about having people—it's about having people who know exactly what to do the second they get the call, without needing to ask for permission.

This process flow diagram breaks down the four pillars that have to be activated in tandem for a cohesive, effective response.

As you can see, activating people, refining processes, leveraging partnerships, and ensuring compliance are all happening at once. They're simultaneous actions, not sequential steps.

Initial Load-Out Strategy: RTE vs. Self-Heating

With your team activated, the next critical decision is what goes on the first trucks out the door. This choice hinges entirely on the scenario you're facing on the ground. For the first 72 hours, your two primary options are Ready-to-Eat (RTE) meals and self-heating meals.

RTEs are invaluable when infrastructure is completely wiped out. Picture the immediate aftermath of a hurricane—power is down, clean water is scarce. RTEs require zero preparation and can be distributed fast to dazed and displaced populations. They're also typically lighter and easier to transport in bulk.

Self-heating meals, on the other hand, offer a huge psychological benefit: a hot meal. In a winter storm power outage or for first responders working in the cold, that hot meal is a massive morale booster. They're heavier and a bit more complex, but their value in certain contexts is immense. Your plan has to lay out clear criteria for which to deploy and when.

For instance, our internal protocol for a coastal flood response prioritizes 70% RTE and 30% self-heating on the initial trucks. The RTEs provide broad, immediate coverage, while the self-heating meals are earmarked for shelters and response teams who need that extra boost.

Here’s a quick tactical comparison to help guide your load-out decisions in those critical first hours.

First 72-Hour Load Plan Comparison: RTE Vs. Self-Heating Meals

| Factor | Ready-to-Eat (RTE) Meals | Self-Heating Meals |

|---|---|---|

| Best Use Case | No power, no clean water, widespread infrastructure damage (e.g., Cat 5 hurricane, major earthquake). | Cold weather events, power outages where water is available, feeding first responders and shelter populations. |

| Logistics | Lighter weight, more units per pallet. Simpler to store and distribute. | Heavier and bulkier due to heating element. Requires user instruction. |

| Prep Needed | None. Open and eat. | Minimal. Activate heating element with water/saline packet. |

| Morale Impact | High (provides immediate calories and relief). | Very High (provides comfort of a hot meal in a crisis). |

| Cost Per Meal | Lower. | Higher due to technology. |

| Shelf Life | Typically 3-5 years. | Typically 2-3 years. |

Ultimately, the right choice depends on a rapid assessment of the disaster zone. Having clear, pre-defined load plans based on likely scenarios in your region will save you from having to make these calls from scratch when every second counts.

Tactical Planning for Mixed Truckloads

No single product can meet every need. The most effective emergency food distribution services rely on smart, mixed truckloads that balance nutrition, ease of use, and shelf stability. Think of a well-planned mixed truck as a self-contained, mobile solution.

Your checklist for a mixed truckload should always include:

- Core Calories: A solid base of either RTE or self-heating meals.

- Hydration: Bottled water is absolutely non-negotiable.

- Snacks & Supplements: High-energy bars, crackers, and nutrient-dense items for kids and seniors.

- Shelf-Stable Staples: For longer-term needs, including items like shelf-stable milk, canned goods, and cereals.

By pre-kitting these items or having clear pallet configurations ready to go in your warehouse, you can load trucks faster and more efficiently. This approach ensures that from the moment those truck doors open, you're delivering a comprehensive solution that addresses the immediate and varied needs of a community in crisis.

Mastering the Supply Chain From Warehouse to Community

Effective emergency food distribution services don’t just appear out of thin air; they're the result of a meticulously planned logistics ballet. That journey from a warehouse pallet to a family's table is where good intentions become tangible, life-sustaining aid. This is the moment that requires a robust supply chain built to handle immense pressure and scale at a moment's notice.

Once you move past the initial deployment, the real work begins: establishing a sustainable, trackable flow of goods. This isn't a job for makeshift operations. Success hinges on partnering with a seasoned, FDA-registered Third-Party Logistics (3PL) provider who brings the infrastructure and compliance know-how to the table.

This need for sophisticated systems didn't develop overnight. It's been building for years against a backdrop of worsening hunger trends across North America. This reality underscores the urgent demand for scalable, compliant solutions—like Nutrition Security kits and Food-is-Medicine programs—designed to reach food banks, government agencies, and tribal communities nationwide.

The Power of Integrated Technology

When you're managing a large-scale response, technology becomes your central nervous system. Integrating systems like Electronic Data Interchange (EDI) and a Warehouse Management System (WMS) isn't a "nice-to-have"; it's completely non-negotiable for real-time tracking and scalability.

An EDI connection automates the flow of information between you, your suppliers, and your 3PL partner. That means purchase orders, shipment notices, and invoices are transmitted instantly, cutting out manual data entry errors and saving critical hours when every minute counts.

Meanwhile, a WMS gives you a real-time, bird's-eye view of every single item in the warehouse, from the moment it hits the receiving dock to its final shipment. This level of visibility is what allows logistics chiefs to make smart decisions on the fly, redirect shipments based on changing needs, and maintain a clear chain of custody for every box of food.

Smart SKU Management and Kitting

Let's be clear: not all food aid is created equal. Thoughtful SKU (Stock Keeping Unit) management and smart kitting strategies are absolutely essential for meeting diverse community needs with dignity and respect. This goes far beyond just handing out calories; it’s about providing the right food.

- Culturally Relevant Foods: A standard-issue box might not meet the dietary or cultural needs of the community you're serving. Proactively sourcing and kitting culturally connected foods—like masa and beans for Hispanic communities or specific grains for immigrant populations—shows respect and ensures the food will actually be eaten.

- OAA-Compliant Senior Boxes: Seniors have specific nutritional needs defined by the Older Americans Act (OAA). Kitting these boxes requires careful component selection to create balanced, low-sodium, and easy-to-prepare meals that genuinely support their health.

- Multi-Day Meal Kits: For programs like CACFP or SFSP Rural Non-Congregate, multi-day kits are a lifeline. These boxes must contain all required meal components, including shelf-stable milk, offering a complete nutritional solution for several days at a time.

A key part of this is creating volunteer-friendly Standard Operating Procedures (SOPs) for kitting. Simple, visual instructions for assembling different kits ensure consistency and speed, even when you're working with a new or inexperienced workforce.

Navigating Critical Compliance Details

In the world of food distribution, compliance is safety. A single misstep can have devastating consequences, making rigorous adherence to regulations a core operational function. You absolutely have to partner with a 3PL that lives and breathes these rules.

The supply chain is more than just trucks and boxes. It's a system of trust built on a foundation of technology, precise inventory management, and unwavering compliance with food safety regulations.

Here are a few compliance areas that demand your full attention:

- Allergen-Segregated Storage: Peanuts, dairy, soy, and other common allergens must be stored in designated, physically separate areas within the warehouse to prevent cross-contamination. A robust WMS is your best friend here, helping enforce and track these critical protocols.

- Cold-Chain Rules: Items like shelf-stable milk might not need constant refrigeration, but they do have specific temperature thresholds. They can't be stored in extreme heat. Your 3PL must monitor and log warehouse temperatures to protect the cold chain and ensure product integrity.

- Managing Shelf Life: Every food item has an expiration date. A "First-In, First-Out" (FIFO) or "First-Expired, First-Out" (FEFO) inventory system, managed through the WMS, is crucial. It ensures older stock gets used first, which minimizes waste and prevents the distribution of expired goods.

Mastering the supply chain also means proactively strengthening your supply chain with logistics support to head off critical disruptions before they happen. An effective operation requires a seamless fusion of physical infrastructure and digital oversight.

Getting Compliance and Partnerships Right

To run successful emergency food distribution services, you absolutely need two things: rock-solid compliance and strong partnerships. Think of these not as bureaucratic hoops to jump through, but as the very foundation of your program. They are the guardrails that keep your operations safe, equitable, and sustainable over the long haul.

From a boots-on-the-ground perspective, compliance is all about integrity. It’s what governs how you source food, how you keep it safe, and who you can serve. Partnerships, on the other hand, are your force multipliers—they give you reach and expertise you simply can’t build on your own. At Umoja, we’ve learned these two are inseparable. You can’t scale one without the other.

Making Sense of the Rules

The world of regulatory compliance can feel like a maze, but it’s manageable when you break it down into specific, actionable pieces. It’s less about memorizing rulebooks and more about weaving compliant workflows into your day-to-day operations. When you do that, you're not just preventing costly mistakes; you're ensuring you are always audit-ready.

A classic example, and a critical one, is the Buy American provision baked into government contracts. This clause mandates that food products must be grown, sourced, and manufactured right here in the U.S. The best way to handle this is to build the requirement directly into your procurement process from the start.

Here’s some straightforward contracting language you can adapt:

"Pursuant to the Buy American Act, all agricultural commodities and food products delivered under this contract must be of domestic origin and processed in the United States, its territories, or possessions, unless a specific waiver has been granted. Supplier must provide documentation certifying the origin of all products upon request."

This kind of clear, direct language shifts the burden of proof to the supplier and creates the paper trail you need. It’s a simple but incredibly powerful tool for staying compliant.

Building Workflows for Different Program Needs

Every program has its own unique set of compliance hurdles. A WIC mobile shopping and home delivery service, for instance, demands a pretty sophisticated approach to inventory. Your system needs to handle what we call "inventory-aware substitutions." If a specific brand of WIC-approved cereal is out of stock, your platform has to be smart enough to automatically suggest a compliant alternative, not just any other cereal.

Likewise, if you’re running a non-congregate rural meal program, you have to nail the parent pick-up process. You need a consistent, documented way to verify who is picking up the meals and confirm how many eligible children they're collecting for. This could be a simple sign-in sheet or a digital app, but whatever you choose, it must be consistent and trackable.

Here are a few more real-world compliance checkpoints to consider:

- Food-is-Medicine: These programs live and die by their outcomes. For a diabetes program, you'll need to track metrics like A1C levels. For hypertension, it’s blood pressure. This data is what proves the program's value to your healthcare partners.

- Parent Pick-Up (Rural Non-Congregate): You need clear rules for proxy pick-ups. It’s common for a parent to ask a neighbor to grab their meals. To allow this without opening the door to fraud, you need a simple, documented authorization process.

- WIC Home Delivery: Your delivery team needs strict protocols, especially when milk is involved. The workflow has to allow for no-contact delivery while still protecting the cold chain.

Forging Partnerships That Amplify Your Impact

Let’s be honest: no single organization can solve hunger alone. Strategic partnerships are what allow you to fill critical service gaps, build local trust, and truly amplify your impact. For any emergency food distribution service, these collaborations are non-negotiable.

Community-Based Organizations (CBOs) are your eyes and ears on the ground. When you partner with local churches, food pantries, and community centers, you gain immediate access to distribution points that are already trusted by the people you want to serve. This local knowledge is invaluable for understanding real-time needs and overcoming distribution barriers.

Working with Tribal programs demands a partnership built on mutual respect for sovereignty and a deep cultural understanding. Collaborating directly with tribal governments ensures the food you provide is not just nutritious but also culturally connected and distributed in a way that aligns with their community’s values.

Finally, partnerships with healthcare plans are opening up exciting new avenues for Food-is-Medicine programs. A managed Medicaid plan might fund a 12-week grocery box program for members with diabetes. They'll rely on you to handle the food sourcing, kitting, and home delivery. It’s a symbiotic relationship where they can address the social determinants of health, and you can focus on your core mission of feeding people.

Executing Flawless Last-Mile Distribution

Let's be honest: the final mile is where your entire operation either succeeds or fails. You can have the most meticulous supply chain, flawless compliance checks, and perfect warehouse logistics, but none of it matters if the food doesn't actually reach the people who need it.

This last step is the most personal and visible part of emergency food distribution services. It’s the handshake, the doorstep drop-off, the human connection. It demands nothing less than flawless execution.

Success here isn’t about a one-size-fits-all approach. It's about building flexible, well-rehearsed workflows that can adapt to different situations. The two models that form the backbone of last-mile distribution are home delivery and centralized parent pickup sites. Each serves a unique purpose and requires its own operational playbook.

The need for these refined models is only getting sharper. For instance, recent analyses project a rising need for emergency food across the globe, with North America seeing significant growth fueled by increased disaster awareness. This global picture makes it clear just how vital efficient, scalable last-mile solutions are. For a deeper dive into these trends, you can review the latest food assistance outlook brief.

Perfecting Home Delivery Workflows

Home delivery is an absolute lifeline, especially for homebound seniors, families who don't have transportation, and people living in remote rural areas. It's also a logistical puzzle that demands tight coordination to be both efficient and secure.

First off, smart route planning is non-negotiable. If you're dealing with hundreds or thousands of addresses, using route optimization software is the only way to go. This tech is a game-changer—it groups stops geographically, slashes drive time, and gives drivers turn-by-turn directions. The impact on fuel costs and delivery times is massive.

Next, you need a rock-solid proof-of-delivery protocol. A simple photo of the box on the doorstep, timestamped and geotagged, has become the industry standard for no-contact drop-offs. This small step protects your organization from claims of non-delivery and creates a clean audit trail for every single kit.

Finally, managing no-contact drop-offs is all about clear communication. Automated text messages are critical here. One text should go out when the delivery is on its way, and another should confirm it’s been dropped off. This simple workflow ensures people can retrieve their food promptly and safely.

Designing Dignified Pickup Sites

For serving a large number of people in a concentrated area, nothing beats the efficiency of a centralized pickup site. The secret to getting it right is creating a process that is not just fast, but also treats every single person with dignity and respect.

It all starts with site selection. Partner up with trusted local institutions—think schools, churches, or community centers. These spots are familiar to residents and usually have the infrastructure you need, like big parking lots and a built-in network of volunteers.

The goal of a pickup site should be to make receiving help as easy and dignified as possible. A well-managed traffic flow and compassionate volunteers can transform a stressful experience into a positive one.

One of the biggest operational hurdles is managing traffic flow. A well-designed drive-thru model with clear signage, dedicated lanes, and volunteers directing cars can prevent gridlock before it starts. Don't forget about walk-up participants; they need a separate, safe, and clearly marked line to keep things orderly.

Volunteer coordination is the human element that makes it all click. Appoint a volunteer lead to run a quick pre-event huddle. They can assign roles—check-in, traffic control, loading boxes—and field any questions. Giving volunteers vests, water, and clear instructions empowers them to serve with confidence and empathy. You can see more about how we build our kitting programs to be volunteer-friendly and operationally tight.

Sample CACFP Multi-Day Kit Pack List (5-Day)

Sometimes, a concrete example is the best tool for planning. To help guide your menu development and procurement, here’s a detailed sample of a compliant, shelf-stable 5-day meal kit for CACFP programs, a common request in large-scale emergency food distribution services.

This table breaks down how to build a kit that's nutritious, compliant, and easy for families to use.

| Component | Item Example | Quantity | Compliance Notes |

|---|---|---|---|

| Breakfast Cereal | Individual Bowl Packs (Whole Grain) | 5 | Must meet USDA whole-grain rich criteria. |

| Shelf-Stable Milk | 8 oz UHT Milk Boxes (1% Low-Fat) | 5 | Critical for CACFP compliance; cold-chain rules for storage must be followed. |

| Lunch Protein | Canned Tuna or Chicken | 3 | Paired with whole grain crackers for a complete meal component. |

| Lunch Alternative | Shelf-Stable Hummus Cups | 2 | Provides a vegetarian option and variety. |

| Fruit | Individual Fruit Cups (in 100% juice) | 5 | Must be packed in juice, not syrup, to meet nutritional standards. |

| Vegetable | Individual Vegetable Cups | 5 | Provides essential nutrients and meets meal pattern requirements. |

| Snack | Whole Grain Crackers | 5 packs | Serves as a versatile component for lunch or a separate snack. |

This sample list acts as a practical template for sponsors. The final piece of the puzzle is having reporting templates to track these kits and gather feedback, which allows you to constantly improve your last-mile execution.

Putting It All Together: Your Blueprint for a Resilient Response

Building a truly effective emergency food distribution service is never about just one thing. It's about how four critical pieces lock together: your people, process, partnerships, and compliance. We’ve walked through the operational nuts and bolts, but real resilience is born from how seamlessly these elements work in concert.

Think about it. A well-drilled rapid response team is only as good as the mobilization plan they’re running. A sophisticated supply chain will quickly grind to a halt without compliant processes and the strength of pre-vetted 3PL partnerships backing it up.

Every single step is linked. From the zero-hour calls you make in the first 72 hours to that final, dignified hand-off during a last-mile home delivery, the chain is only as strong as its weakest link.

This playbook is designed to give you actionable steps, not just high-level theory. Our experience at Umoja has taught us that preparedness isn’t a binder on a shelf; it’s an active, living thing. It means having clear workflows for everything—from sorting mixed truckloads of RTE and self-heating meals to running a smooth parent-pickup site—all while keeping a sharp eye on regulatory demands.

The real goal here is a proactive, scalable system that meets community needs with dignity and absolute efficiency. When you get the planning right, you build a response that doesn't just react to a crisis—it’s already waiting for it.

Use these strategies to stress-test and sharpen your own operations. When you build on these foundational pillars, you empower your organization to deliver life-sustaining food when it matters most. You become a reliable lifeline for the communities you serve. That level of readiness is the true measure of a resilient emergency food response.

On-the-Ground Questions, Answered

When you're in the thick of planning an emergency food distribution, a lot of specific, practical questions come up. We've been there. Here are some of the most common challenges we see and how we recommend tackling them.

How Should We Really Manage Distribution in Rural Areas?

Getting food to families in rural areas, especially for programs like SFSP Rural Non-Congregate, is a unique logistical puzzle. Forget a one-size-fits-all approach. The most effective strategy we've seen is a hybrid model.

It starts with partnering with trusted local entities. Think post offices, community centers, even local churches. These become your "mini-hubs" for the last mile. From there, you can coordinate home delivery routes using 3PL partners who actually know the backroads. For those places where delivery just isn't feasible, you need well-communicated, scheduled parent pickup windows at these hubs. The key here is to make sure your kits are entirely shelf-stable; it simplifies everything for your partners and the families receiving them.

What's the Best Way to Handle Dietary Restrictions?

This is where proactive planning is non-negotiable. Don't wait until you're on-site to figure this out. Your procurement strategy should intentionally include a variety of culturally connected SKUs from the very beginning. Then, use a simple intake form—either during pre-registration or at the pickup site—to flag major allergens and dietary needs.

We've found that pre-kitting specific boxes for common needs, like an "Allergen-Free Box," is a game-changer. It dramatically cuts down wait times and, most importantly, keeps people safe.

If you’re working with a 3PL, make sure their Warehouse Management System (WMS) can track and segregate these specialized kits. It’s the only way to ensure the right box gets to the right person without chaos.

How Can We Nail Buy American Compliance on a Tight Timeline?

Compliance isn't something you can figure out in the middle of a crisis. It all comes down to your supplier relationships. You need to be working with vendors who specialize in compliant sourcing and can provide the paperwork without a hassle. The best practice is to have pre-vetted supplier lists with Buy American compliant products ready to go before disaster strikes.

When you're issuing purchase orders, the Buy American clause must be explicitly included. Require your suppliers to certify compliance in writing. This documentation isn't just a formality; it's critical for any audits down the road. If you're in a pinch and need something last-minute, your protocol should be to prioritize compliant products first and rigorously document any exceptions if a compliant option simply isn't available.

Ready to build a more resilient and compliant food distribution program? Umoja Health provides the expertise and logistical support to help you scale your operations with confidence. Visit https://umojahealth.com to learn how we partner with organizations like yours.